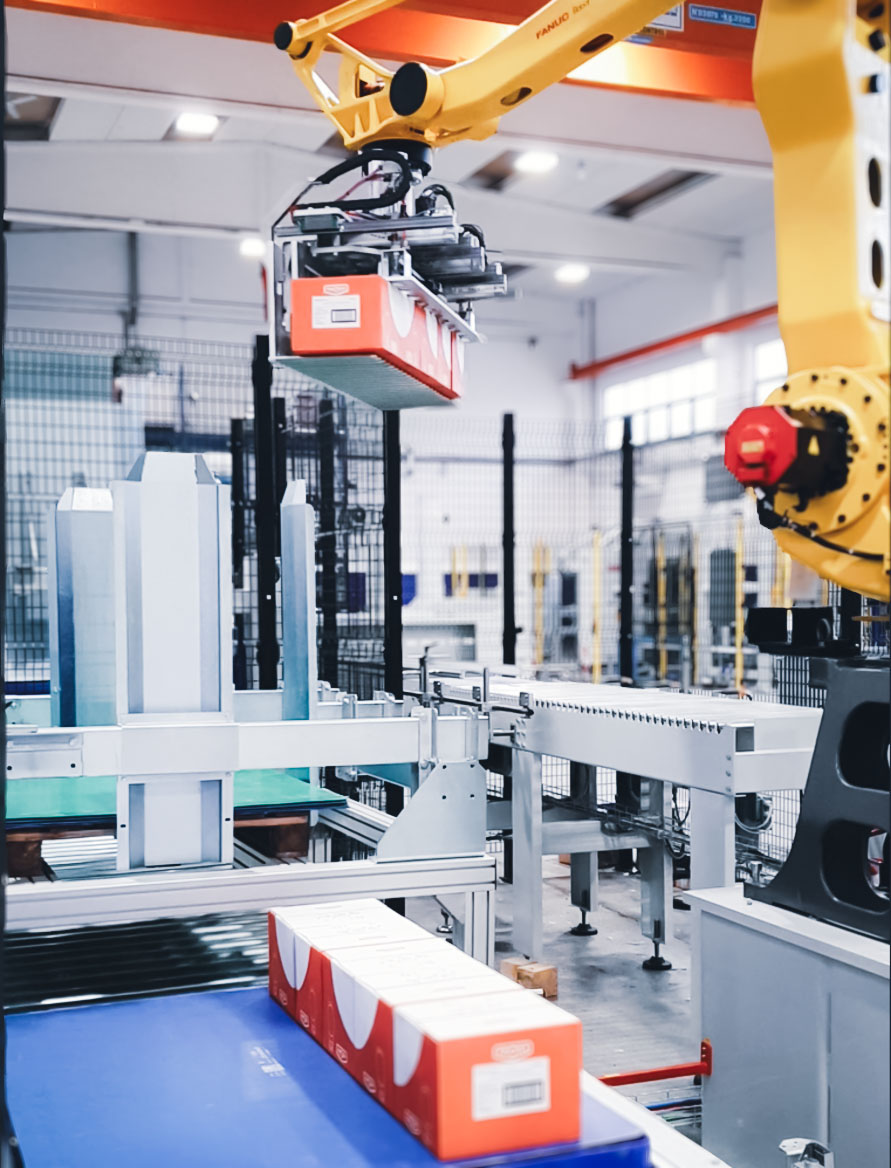

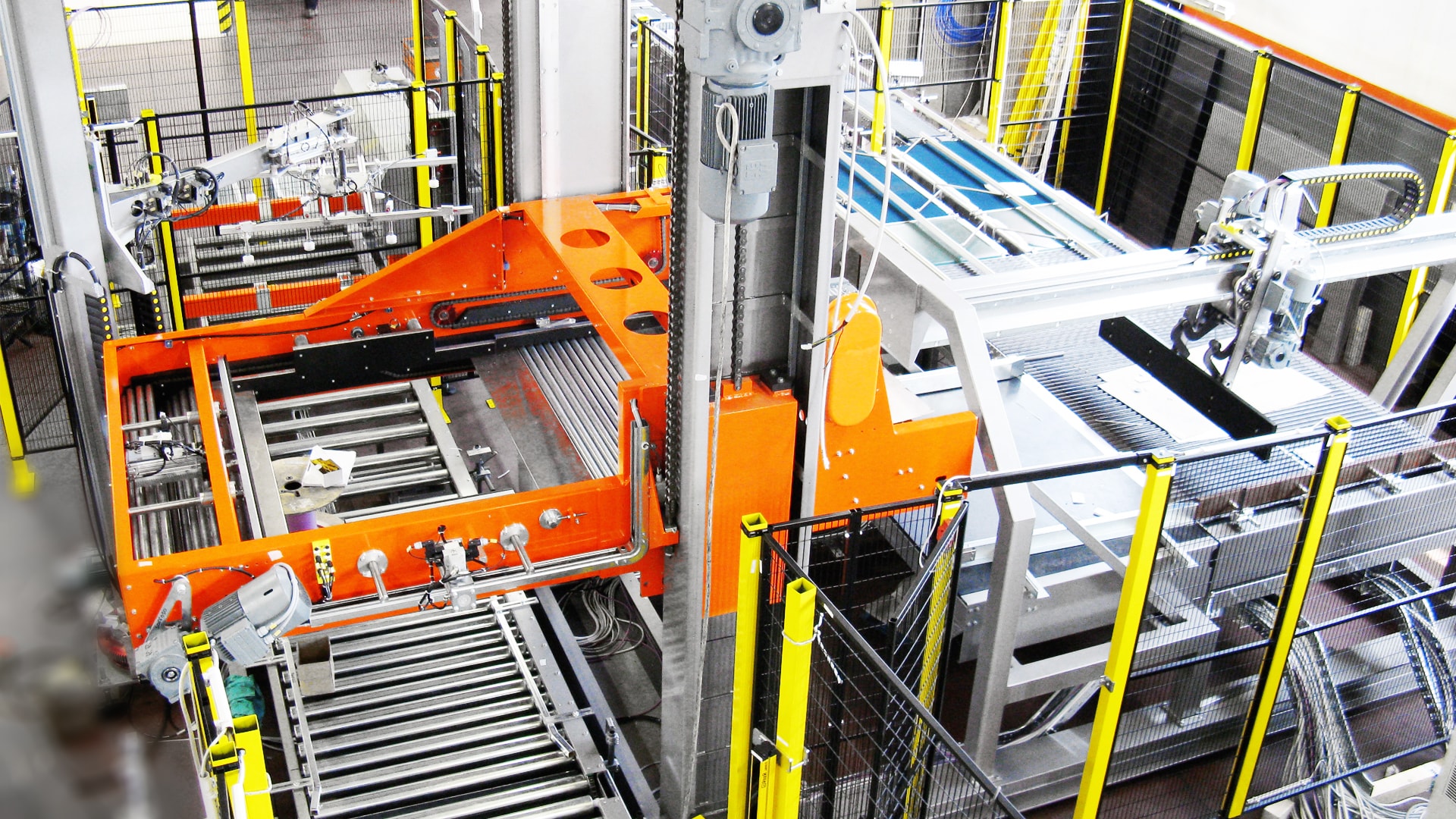

Palletizers

Robotic and traditional palletizers for many type of containers like pouches, cans, jars and bottles.

Our robotic and traditional palletizers can be easily integrated with existing processing and packaging lines, or combined with a complete CFT packaging or processing plant.

CFT 810

-

Industries:

- Beverage

- Edible Oil

- Fruit

- Ketchup, Sauces, Jams

- Milk & Dairy

- Other Foods

- Tomato

- Vegetables

-

Max Capacity:

- 4 cycles/min.

-

Container:

- Buckets

-

Technology:

- Robotic

Benefits

Ensuring accurate and consistent product placement, minimizing errors in logistics processes.

These robots seamlessly integrate with existing production lines, ensuring smooth workflow.

Both robotic palletizers and depalletizers enhance production rates by working without breaks.

Features

Features

- Vacuum grip head

- Lifting up to 200 kg

- Manageable sizes: from 6 to 30 liters

CFT 806

-

Industries:

- Beverage

- Edible Oil

- Milk & Dairy

- Other Foods

- Vegetables

-

Max Capacity:

- 4 cycles/min.

-

Container:

- Bundles

-

Technology:

- Robotic

Benefits

These robots seamlessly integrate with existing production lines, ensuring smooth workflow.

With minimal maintenance needs, these robots ensure consistent operation, minimizing downtime and maximizing output.

Both robotic palletizers and depalletizers enhance production rates by working without breaks.

Features

Features

- Single fork grip head

- Lifting up to 315 kg

- Up to 20 bundles per minute

CFT 805

-

Industries:

- Beverage

- Edible Oil

- Milk & Dairy

- Other Foods

- Vegetables

-

Max Capacity:

- 4 layers/min.

-

Container:

- Cans

- Jars (Glass)

- Tanks

-

Technology:

- Robotic

Benefits

These robots adapt to various package types, sizes, and weights, offering flexibility in logistics operations.

Ensuring accurate and consistent product placement, minimizing errors in logistics processes.

These robots streamline material handling, improving efficiency and reducing labor costs.

Features

Features

- Magnetic grip head

- Lifting up to 500 kg

- Flap insertion available as option

CFT 804

-

Industries:

- Beverage

- Edible Oil

- Milk & Dairy

- Other Foods

-

Max Capacity:

- 3 cycles/min.

-

Container:

- Bottles (Glass)

- Bottles (PET)

-

Technology:

- Robotic

Benefits

With minimal maintenance needs, these robots ensure consistent operation, minimizing downtime and maximizing output.

These robots adapt to various package types, sizes, and weights, offering flexibility in logistics operations.

These compact robotic systems optimize floor space, making them suitable for diverse warehouse layouts.

Features

Features

- Pneumatic bells grip head

- Lifting up to 315 kg

- Bottles centering device

CFT 803

-

Industries:

- Beverage

- Edible Oil

- Milk & Dairy

- Other Foods

- Vegetables

-

Max Capacity:

- 4 cycles/min.

-

Container:

- Cartons

- Tanks

-

Technology:

- Robotic

Benefits

Suitable for businesses of all sizes, robotic palletizers and depalletizers scale seamlessly to meet growing demands.

Tailorable programming enables these robots to adapt to specific production requirements and changing scenarios.

Advanced algorithms and sensors enhance precision, reducing the likelihood of errors in material handling.

Features

Features

- Lateral grip head

- Lifting up to 315 kg

- Up to 40 bundles per minute

CFT 801

-

Industries:

- Beverage

- Edible Oil

- Milk & Dairy

- Other Foods

- Vegetables

-

Max Capacity:

- 4.5 layers/min.

-

Container:

- Bundles

- Cartons

-

Technology:

- Robotic

Benefits

These robots streamline material handling, improving efficiency and reducing labor costs.

Ensuring accurate and consistent product placement, minimizing errors in logistics processes.

Both robotic palletizers and depalletizers enhance production rates by working without breaks.

Features

Features

- Carbon basket head

- Lifting up to 500 kg

- Up to 90 bundles per minute

- Low or high level entrance

CFT 701

-

Industries:

- Beverage

- Edible Oil

- Milk & Dairy

- Other Foods

- Vegetables

-

Max Capacity:

- 8 layers/min.

-

Container:

- Bundles

- Cartons

-

Technology:

- Non-robotic

Benefits

Provides a trustworthy and consistent performance over time.

Facilitates easy upkeep, minimizing downtime and costs.

Ensures durability and robustness for long-lasting operation.

Features

Features

- Double opening head

- Pallet max height 2,500 mm

- Discharge height: 500 mm

CFT 601

-

Industries:

- Beverage

- Edible Oil

- Milk & Dairy

- Other Foods

- Vegetables

-

Max Capacity:

- 3.5 layers/min.

-

Container:

- Bundles

- Cartons

-

Technology:

- Non-robotic

Benefits

Robust build withstands high loads for long-lasting performance.

Ensures consistent and reliable performance in various production scenarios.

Designed for simplicity in maintenance, minimizing downtime and upkeep costs.

Features

Features

- Double opening head

- Pallet max height 2,200 mm

- Entrance height 800 mm

CFT 506

-

Industries:

- Beverage

- Edible Oil

- Milk & Dairy

- Other Foods

- Vegetables

-

Max Capacity:

- 4.5 layers/min.

-

Container:

- Cans

- Jars (Metal)

-

Technology:

- Non-robotic

Benefits

These palletizers adapt to various packaging, ensuring efficient handling of diverse products.

Ensures rapid and efficient palletizing of full containers with a low-level discharge for convenience.

Incorporates a magnetic head for secure and precise handling of containers during the palletization process.

Features

Features

- Magnetic grip head

- Pallet max height 1,800 mm

- Discharge height: 1,000 mm

CFT 504

-

Industries:

- Beverage

- Edible Oil

- Milk & Dairy

- Other Foods

- Vegetables

-

Max Capacity:

- 4.5 layers/min.

-

Container:

- Cans

- Jars (Metal)

-

Technology:

- Non-robotic

Benefits

These machines deliver precise, repeatable results for consistent stacking patterns.

With its magnetic head, the machine adapts seamlessly to various packaging formats, enhancing versatility.

Featuring a magnetic head, this machine ensures swift and straightforward material manipulation.

Features

Features

- Magnetic grip head

- Pallet max height 1,800 mm

- Discharge height: 1,200 mm

No machine found. Please use fewer filters.