Dryers

Complete series of dryers, both batch and continuous belt type, to cover a wide range of fruits and vegetables.

This machine’s range includes different types of dryers, including spin and air dryers.

Air drying is obtained through the circulation of hot and dry air which extracts moisture from the product passing through it.

The hot and humid air is then partially extracted from the dryer, being replaced with hot dry air. The number of sections and number of conveyors (stages) is determined by the type of product and the working capacities required.

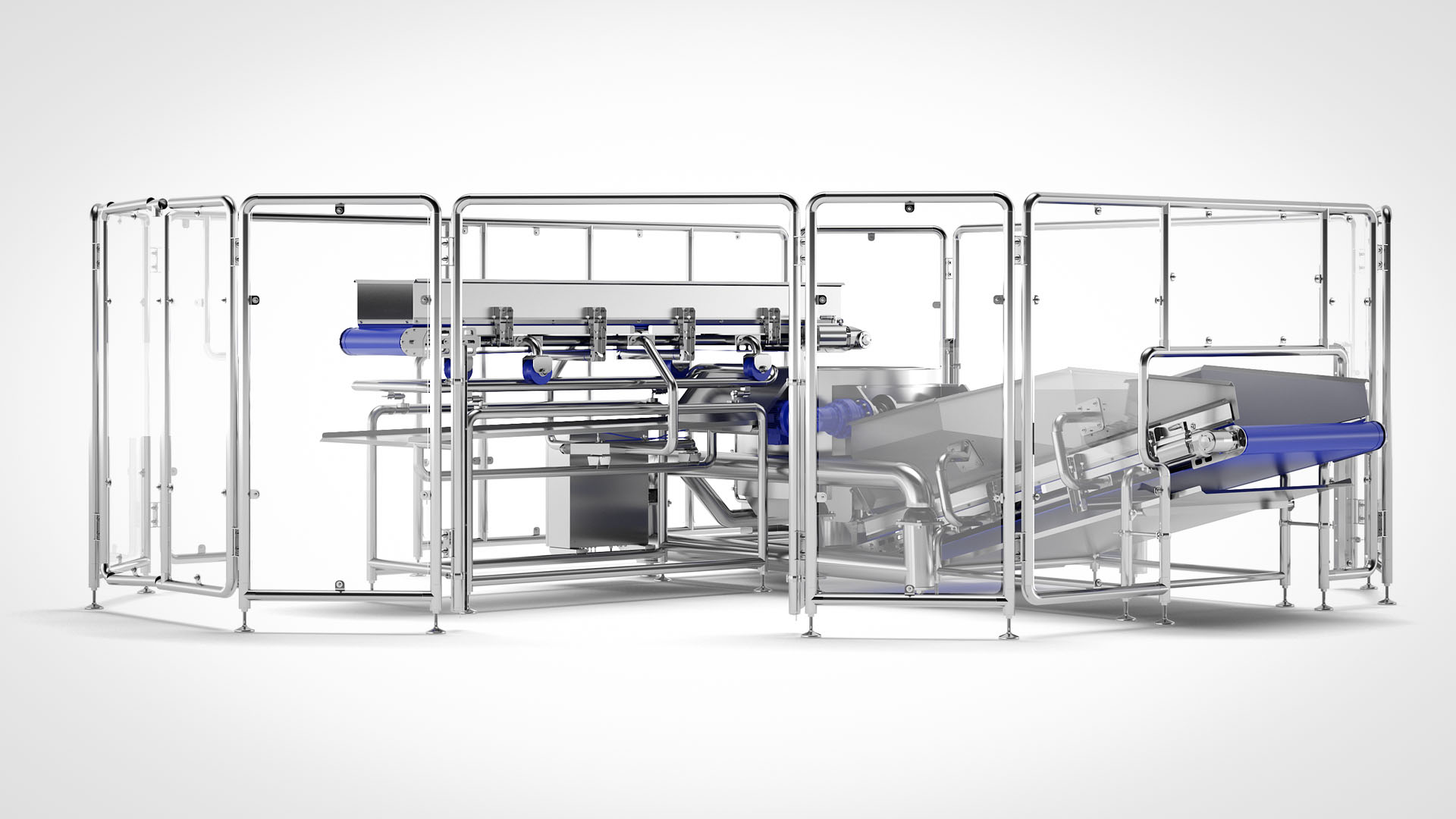

The C-600 spin dryer “Rotodry” has totally transformed the concept of this type of machine, while retaining the technological and operational characteristics of the product. The technical solutions focus on the possibility to access every part of the machine, thereby making cleaning and maintenance operations easier.

PRODUCTS: leaf vegetables, other vegetables

BENEFITS:

- High-cleaning power

- Comfortable working height

- Ease of inspection, the machine has safety barriers all around it where it can be accessed for cleaning and maintenance operations

- Exposed elements without crankcase

- Possibility to load the machine from the sides of the drum (optional)

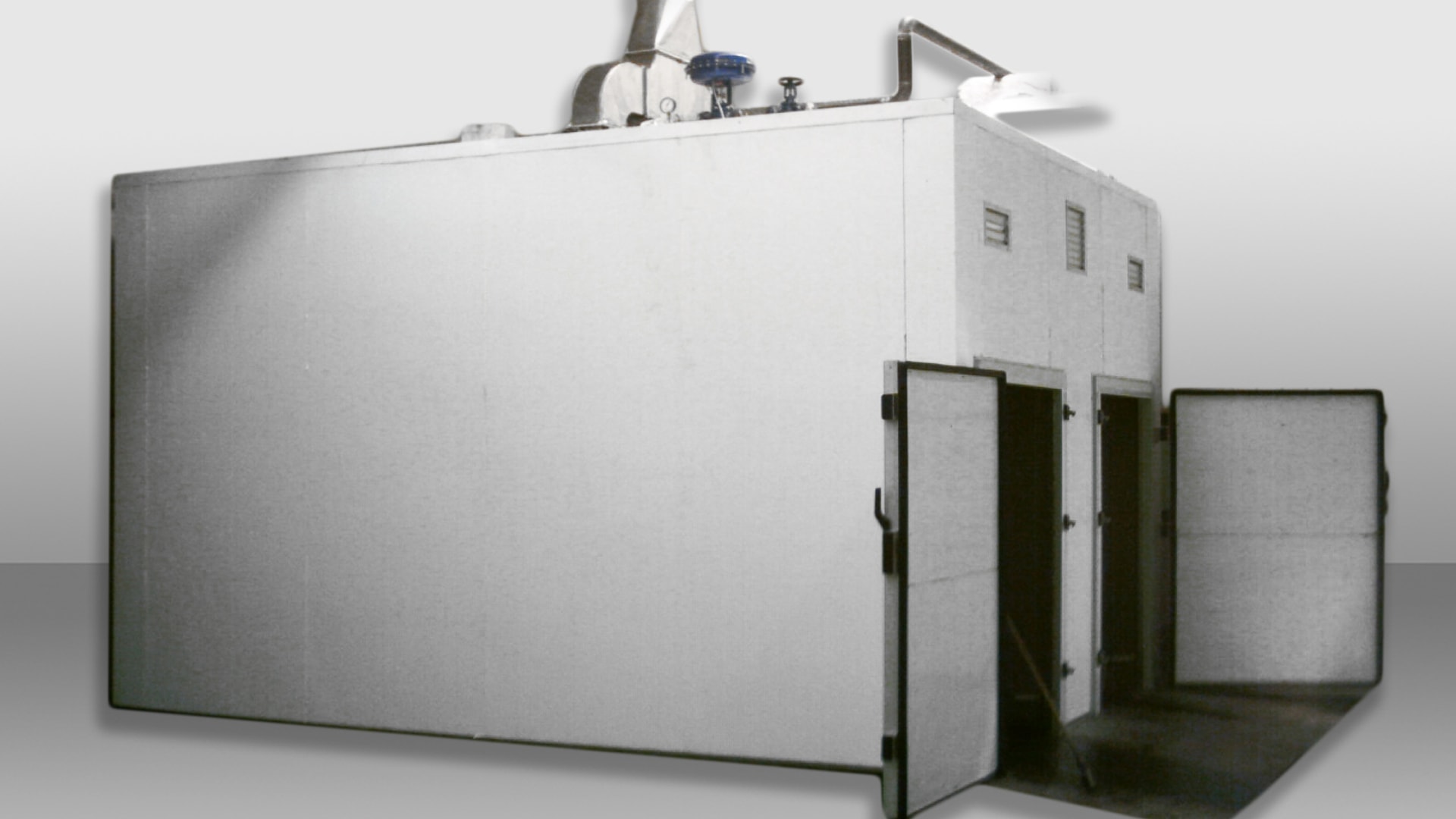

Traydry-S and Traydry-LX Batch

TRAYDRY-S and TRAYDRY-LX are available in 4 models ranging from 2 up to 12 trolleys, with increasing production capacity.

OVERVIEW

The product to be dried is spread (thin layer) on special trays that are manually loaded into stainless steel trolleys.

The trolleys are manually inserted into an insulated cabin: the doors are closed and a drying cycle begins.

A horizontal airflow hits the trays. Airflow direction is automatically reversed in order to obtain higher uniformity of drying conditions.

At the end of the cycle the trolleys are manually extracted from the cabin.

The models of the TRAYDRY-LX family have the following extra features with respect to the S family:

- time-temperature programming

- automatic moisture control of exhaust air

- air speed regulation

- PLC automation

- remote control

PRODUCTS: whole or diced/sliced fruits, whole or diced/sliced vegetables, whole leaf vegetables, aromatic and medicinal herbs

BENEFITS:

- Hygienic trays, easily washable

- Gentle, low-temperature heat treatment thanks to large drying surface

- Particularly suited for sticky products

- Homogeneity of drying conditions thanks to programmable airflow inversion

- High flexibility of operation

- Low cost of spare parts and maintenance activities due to utilization of high quality commercial components

- DRYING CYCLE TIME: from 10 up to 24 hours

Traydry-LXC

TRAYDRY-LXC is available in 3 models ranging from 3 to 5 sections, with increasing production capacity.

OVERVIEW

The product is spread (thin layer) on special trays that are loaded into stainless steel trolleys.

An automatic handling system:

- inserts trolleys with fresh product in one end of the insulated tunnel;

- pushes the entire “train” of trolleys;

- extracts the trolleys with dried product from the other end of the tunnel.

- The drying tunnel is divided in several sections lengthwise featuring independent air circulation, drying temperature, fresh air make-up. Airflow direction is automatically reversed in order to obtain higher uniformity of drying conditions.

PRODUCTS: whole or diced/sliced fruits, whole or diced/sliced vegetables, whole leaf vegetables, aromatic and medicinal herbs

BENEFITS:

- Hygienic trays, easily washable

- Gentle, low temperature, heat treatment thanks to large drying surface

- Particularly suited for sticky products

- Homogeneity of drying conditions thanks to programmable airflow inversion

- Low cost of spare parts and maintenance activities due to utilization of high quality commercial components

- NUMBER OF TROLLEYS: 24, 32, 40

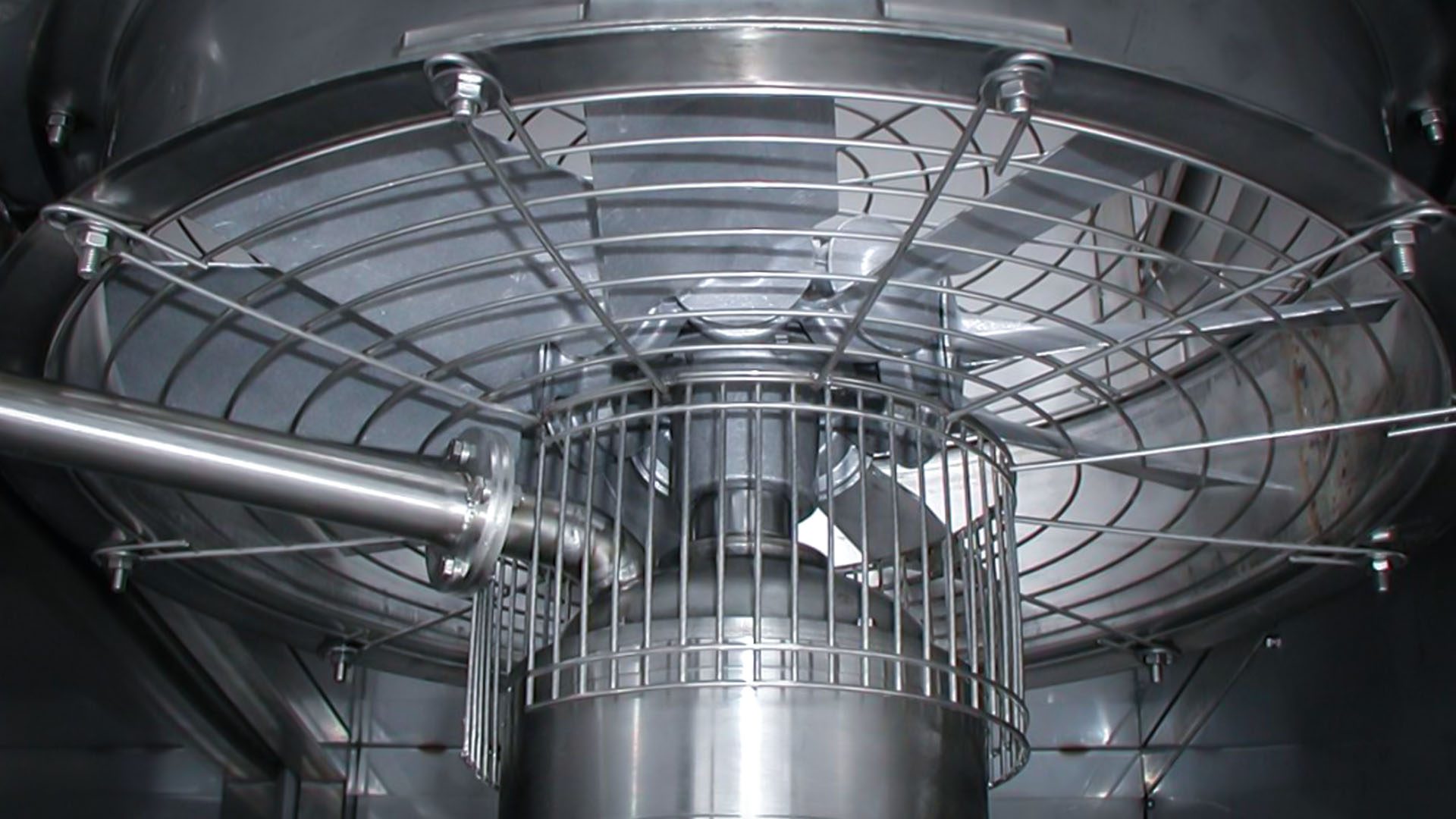

Mecdry MF

MECDRY MF is frequently used as a finisher, after a MECDRY MD dryer, for the equalization of the moisture level within the product.

OVERVIEW

The product to be dried is loaded, in a thick and adjustable layer, on a special heat-resistant linear conveyor. A vertical airflow (bottom-up or top-down) goes across the slats and the product layer. The conveyor system of MECDRY MF is made of several superimposed conveyors. Product is fed on the upper conveyor and falls on the lower conveyor at the end of each path. The speed of each belt is independently regulated, thus allowing for product accumulation.

The horizontal conveyors go across vertical drying sections, which have independent air circulation. Temperature and fresh air make-up are constant in all sections.

The number of sections and conveyors in a MECDRY MF is determined based on the product type and working capacities required.

PRODUCTS: whole or diced/sliced vegetables, whole leaf vegetables, whole or diced/sliced fruits, aromatic and medicinal herbs, suitable for finishing/equalization of partially dried product

BENEFITS:

- Low energy consumption thanks to moisture control of exhaust air

- Gentle, low-temperature heat treatment thanks to large drying surface

- Possibility to “equalize” moisture degree in finished product

- Compact construction

- All structures and conveyor belt made of stainless steel

- No possibility of product contamination thanks to lubrication-free conveyor system

- High mechanical reliability of conveyor

- Low cost of spare parts and maintenance activities due to utilization of high quality commercial components

- INPUT CAPACITY from 400 up to 1.000 KG/h

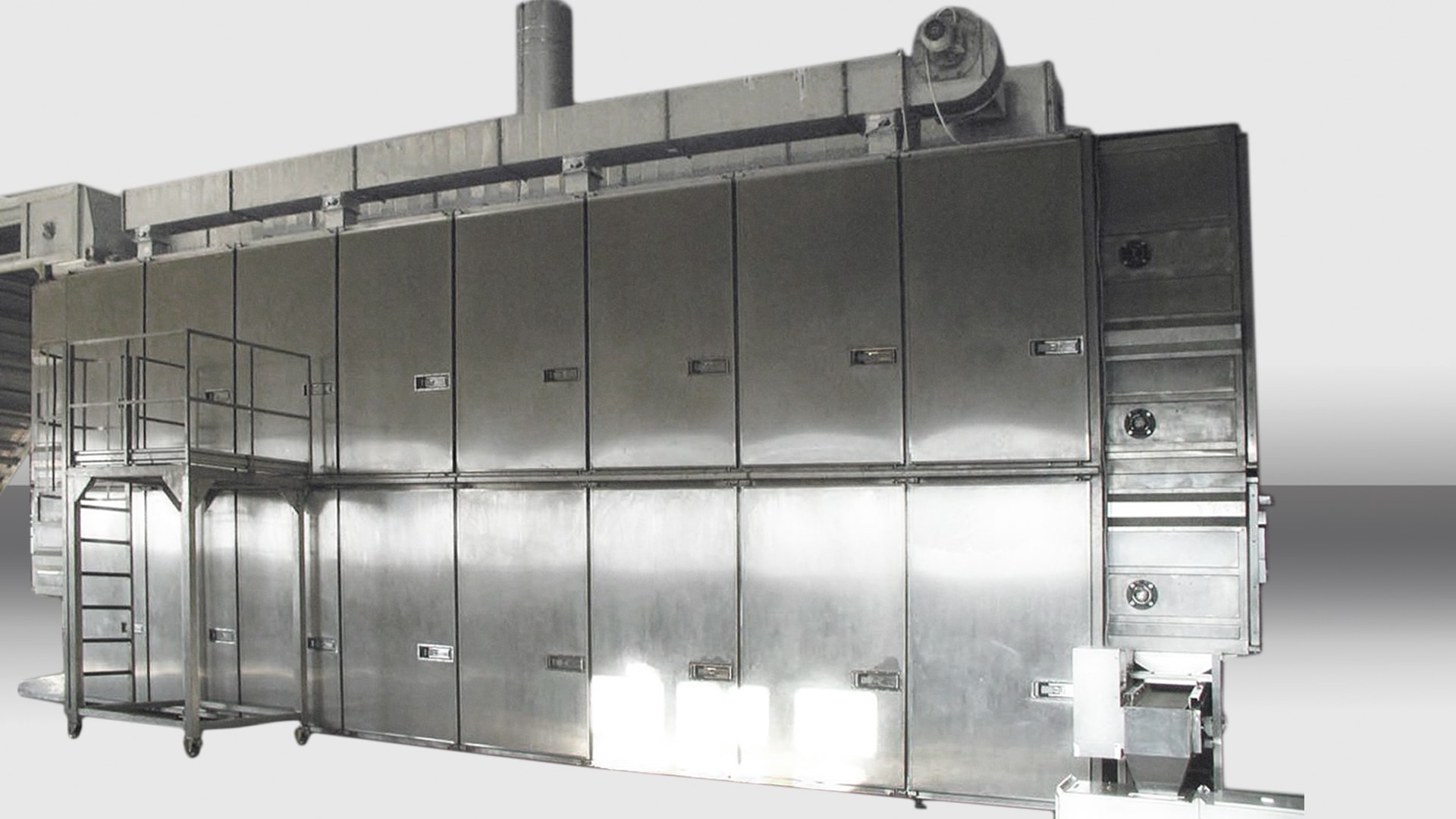

Mecdry MD

The transport system of MECDRY MD is made of one or more conveyors/stages whose speed is independently regulated, thus allowing for product accumulation. The conveyor goes through modular drying sections that have independent air circulation, air heating units, and fresh air make-up. The number of sections and number of conveyors (stages) in a MECDRY MD is determined on the base of product type and working capacities required.

PRODUCTS: whole or diced/sliced vegetables, whole leaf vegetables, whole or diced/sliced fruits, aromatic and medicinal herbs

BENEFITS:

- Low energy consumption thanks to insulated belt connection sections and moisture control of exhaust-air

- High speed heat treatment, particularly effective with high moisture vegetable products

- Modular construction, possibility to increase production capacity by adding new sections

- All structures and transport belt made of stainless steel

- No possibility of product contamination thanks to lubrication-free conveyor system

- High mechanical reliability of conveyor

- High speed heat treatment, particularly effective with high moisture vegetable products

- Low cost of spare parts and maintenance activities due to utilization of high quality commercial components

- HEATING POWER from 500 to 7000 kW