Digital Tomato™: one year later. The value born from data

One year ago, we brought Digital Tomato™ to life—our software for monitoring tomato production—embarking on a journey that has changed the way we observe and optimize the tomato processing process.

This IoT solution is designed to proactively monitor production assets, analyze performance, and support tomato processors in achieving more informed, efficient, and sustainable operations.

The project stems from a simple belief: in factories, knowledge is everywhere, but it often remains trapped inside machines.

Data reveals what the eye cannot see and, when correctly interpreted, becomes a fundamental lever to improve performance, efficiency, and product quality.

Today, after a full season of use, we can share how this approach has begun to transform tomato production lines. It is not just technology—it is a change in mindset.

Measuring to improve

Tomato processing requires a balance between raw material variability, operational continuity, and process precision. Small deviations can have significant consequences.

Digital Tomato™ was created to guide processors through a continuous improvement cycle, thanks to tomato production monitoring that enables them to:

- Measure performance,

- Identify deviations,

- Analyze them in depth,

- Apply corrective actions,

- Verify results.

A simple yet powerful method, transformed into a structured system through the combination of technology, process expertise, and the CFT method.

Today, analysis is supported by our engineers and technicians, while the future points toward advanced automation and artificial intelligence.

Where value is created: 5 key areas

Digital Tomato™ delivers an immediate and tangible impact across several production areas:

- Extract more, discard less

Extraction yield is often invisible to operators. Continuous monitoring makes it possible to quickly identify discontinuities and recover productivity. - Use energy more efficiently

Evaporators are among the most energy-intensive machines. Optimal regulation reduces the evaporation cost per ton of water removed. - Make machines truly available

The software identifies, analyzes, and classifies the main causes of downtime for each machine, enabling targeted and prioritized interventions. - Brix accuracy

Accurate measurement avoids unnecessary energy consumption and increases final yield. - Connecting process and quality

The integration of process data and laboratory data makes it possible to clearly visualize cause-and-effect relationships: parameters such as product temperature and residence time are directly correlated with final color, enabling improvements in product quality and increased yield.

Technological solution and CFT added value

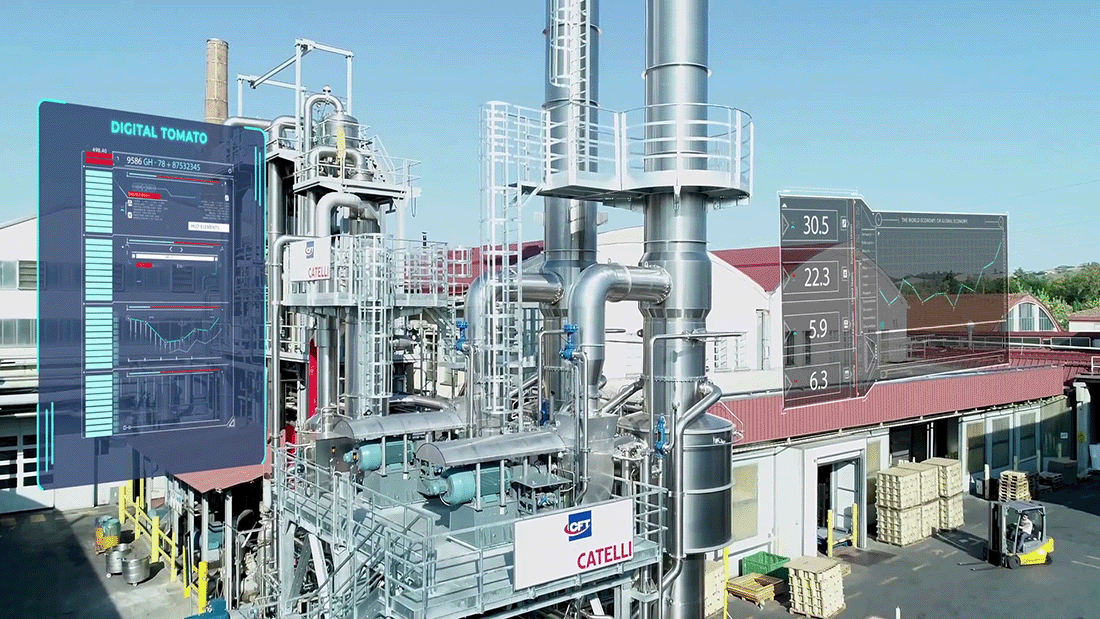

Digital Tomato™ includes two complementary interfaces:

- a simple and intuitive interface for operators, allowing immediate visualization of machine performance status and clearly highlighting deviations from the standard;

- a cloud platform dedicated to managers and production supervisors, featuring energy analyses, process trends, line comparisons, and campaign efficiency.

However, the true value of this technology lies in the service that accompanies it. Every week, the CFT team analyzes the collected data and shares observations and operational suggestions with the customer.

At the end of the season, our team of experts, together with the customer, reviews past performance and identifies potential areas for improvement to set objectives for the following season. This approach fits into a model that rewards the value generated, not merely the cost of the technology.

Digital Tomato™ therefore represents an ongoing collaboration between CFT and the customer: a journey in which data guides decisions, operators increase operational awareness, managers gain clearer insight, and the production line achieves higher levels of stability, efficiency, and sustainability.

Field results: figures from the latest campaign

The campaigns monitored this year have highlighted concrete results thanks to the use of Digital Tomato™, the software for monitoring tomato production. Below are some significant examples:

- Drum filling: precision that translates into value

Thanks to the implementation of a new software algorithm, developed based on the collected data, aseptic fillers improved average accuracy by 10%, without requiring operator intervention.

Across several production shifts, accuracy remained consistently below 100 grams, ensuring greater control and reduced waste. - Energy: optimizing what is already available

In one specific case, Digital Tomato™ detected abnormal energy consumption in the evaporation process.

Following an in-depth analysis, our team identified the possible causes and provided operational guidelines for resolution. The issue was quickly corrected, restoring operating costs to standard levels and avoiding hidden and prolonged extra costs. - More stable machines, more efficient lines

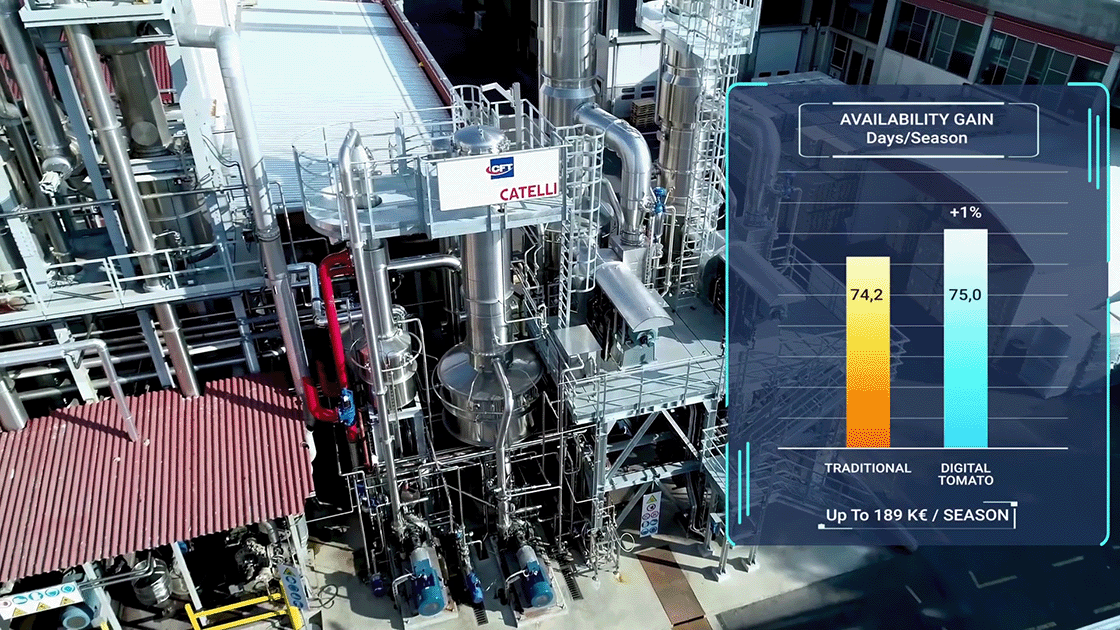

Digital Tomato™ contributed to an increase in plant efficiency thanks to more advanced and informed process control. The main improvements were achieved through the analysis of recurring anomalies responsible for frequent micro-stoppages.

In detail:

- Enzymatic inactivator availability: +2.1%

- Pre-concentrator availability: +4.3%

The overall result is an increase in the line’s average operational availability of +1%, translating into recovered production hours and higher productivity.

In all these cases, data tells what is happening, and our team of experts supports the customer in identifying the best direction, transforming information into concrete action.

Looking ahead: predictive intelligence

The direction is clear: tomato production monitoring software will no longer be limited to describing what happens but will increasingly be able to anticipate it.

This experience represents just a preview of what Digital Tomato™ is set to become: an ecosystem capable not only of identifying deviations but also of predicting machine behavior and implementing the most effective actions, making continuous improvement an increasingly proactive and automated process.

Moreover, this technology can also be applied to other food processing lines, further expanding the possibilities for industrial process optimization.

And this is only the first season.

The next promises even more value, more automation, and increasingly intelligent use of data.