Peelers

Abrasive or steam peelers capable of processing a wide range of products.

Our peelers include advanced high vacuum technology, eliminating contact between product and water resulting in non-polluting liquid discharge.

Vesuvio Millenium

-

Industries:

- Tomato

-

Min. Capacity:

- 720 tons/day

-

Max Capacity:

- 2,200 tons/day

Benefits

Low heat penetration and delicate product handling preserve the original tomato consistency and sensory features.

Low peeling temperature (106-108 °C) minimizes energy consumption.

Minimal maintenance costs, ensuring economic operation.

Independent adjustment of water and steam temperature, heated water level, and dwell time enhances control.

Features

Features

- Pressurized chamber with a rotor for efficient and gentle peeling

- Effortless process management and control for enhanced operational efficiency

- Processes up to 90 t/h of fresh tomatoes efficiently, ensuring productivity

- Tailored to specific tomato characteristics, ensuring adaptability to production needs

- Dual steam and water peeling for optimized efficiency and performance

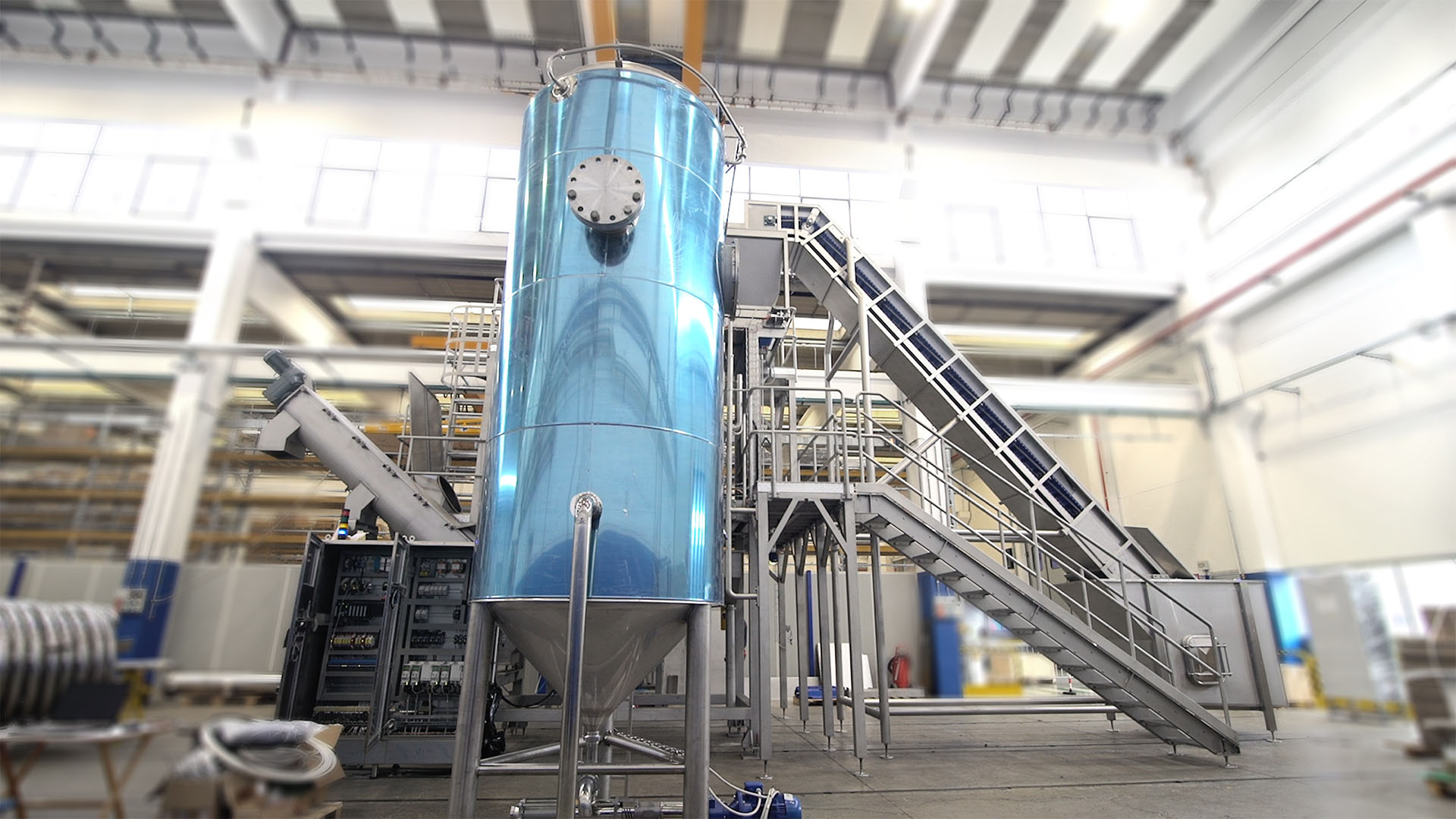

Tsp Peeler

-

Industries:

- Tomato

- Vegetables

-

Min. Capacity:

- 240 tons/day

-

Max Capacity:

- 1,500 tons/day

Benefits

High peeling efficiency achieved through a low product level and parallel steam flow.

Offers great flexibility and process control for customized peeling requirements.

Fully automatic with minimal operator intervention, enhancing efficiency.

Uniform heating due to heating vessel design and parallel steam flow.

Features

Features

- Utilizes a mono pump with a hopper for efficient recovery of juice

- Automatic washing system ensures cleanliness and hygiene

- Frame made of stainless steel or galvanized steel for durability and customization

- Electric control panel with a touch-screen monitor or PC for easy machine operation

- Handles different products such as tomatoes, carrots, and potatoes

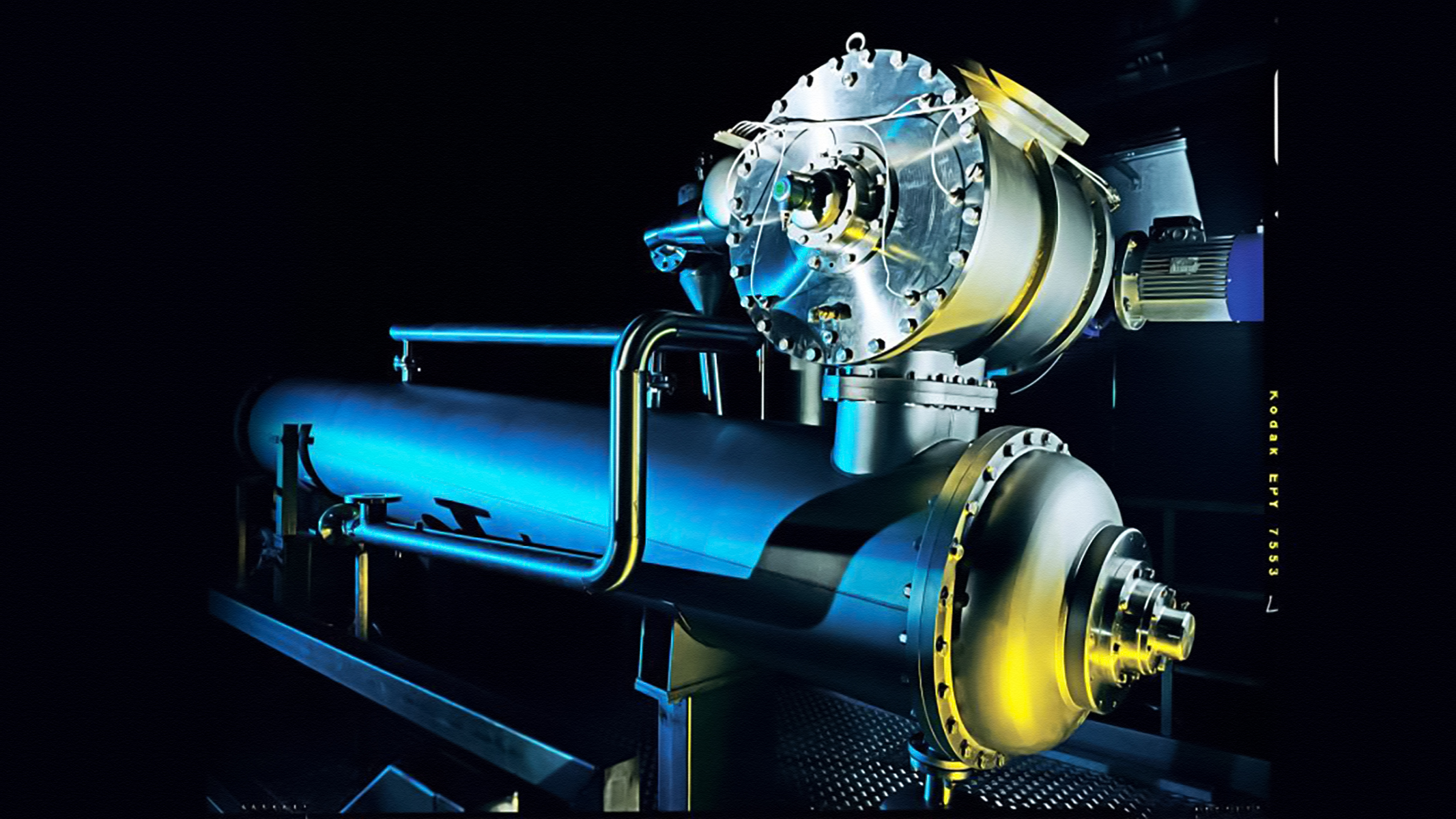

Steam Peeler Geyser

-

Industries:

- Vegetables

-

Min. Capacity:

- 48 tons/day

-

Max Capacity:

- 600 tons/day

Benefits

Steam peeling ensures quick and efficient removal of skin from carrots and potatoes, contributing to increased productivity.

Minimizes waste during the peeling process, optimizing the yield of usable produce.

Provides uniform peeling across different sizes and shapes of carrots and potatoes.

Steam acts as a natural sterilizing agent, contributing to improved hygiene and sanitation.

Features

Features

- Specifically engineered for carrots and potatoes peeling

- Special vessel design for optimal product mixing and perfect treatment

- Complete stainless-steel structure including pressure vessel

- Ability to prepare different kinds of final products

No machine found. Please use fewer filters.