Vegetable processing

Vegetable processing technologies featuring precision, uniformity and efficiency.

Optimize vegetable processing with our machinery for precision sorting, uniform cooling and perfect drying.

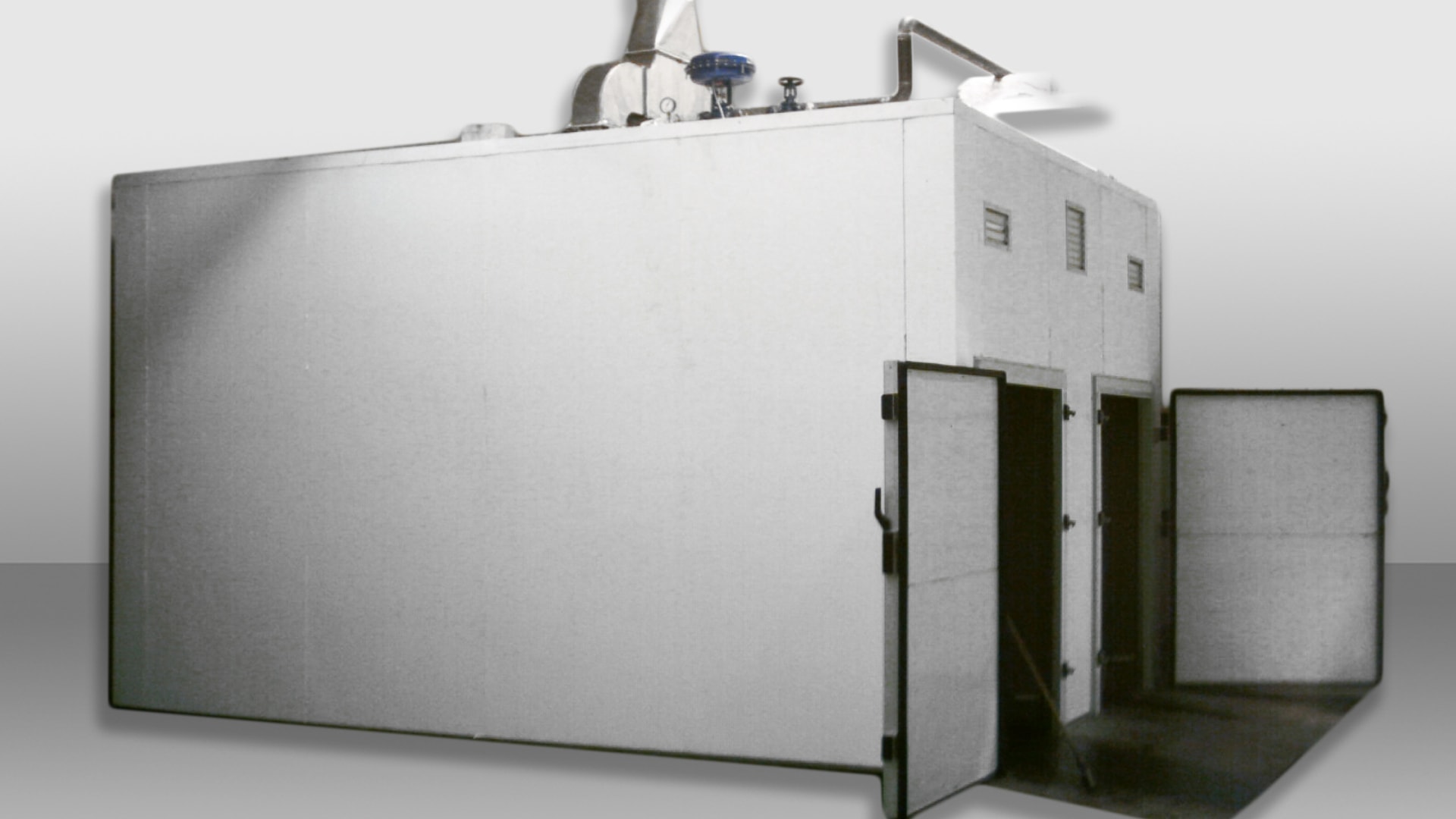

Traydry-SLX

-

Industries:

- Vegetables

Benefits

4 models (2-12 trolleys) offer flexibility, matching varied production needs efficiently.

Optimized design enhances drying efficiency, minimizing energy consumption for sustainable operation.

Consistent results across models ensure high-quality dried vegetables, meeting industry standards reliably.

Features

Features

- Optimize drying with programmable airflow inversion for uniform conditions and consistent result

- Suitable for sticky products, the design reduces the risk of sticking, ensuring an efficient and smooth drying process

- Customize drying cycle from 10 to 24 hours for flexibility in meeting diverse drying needs

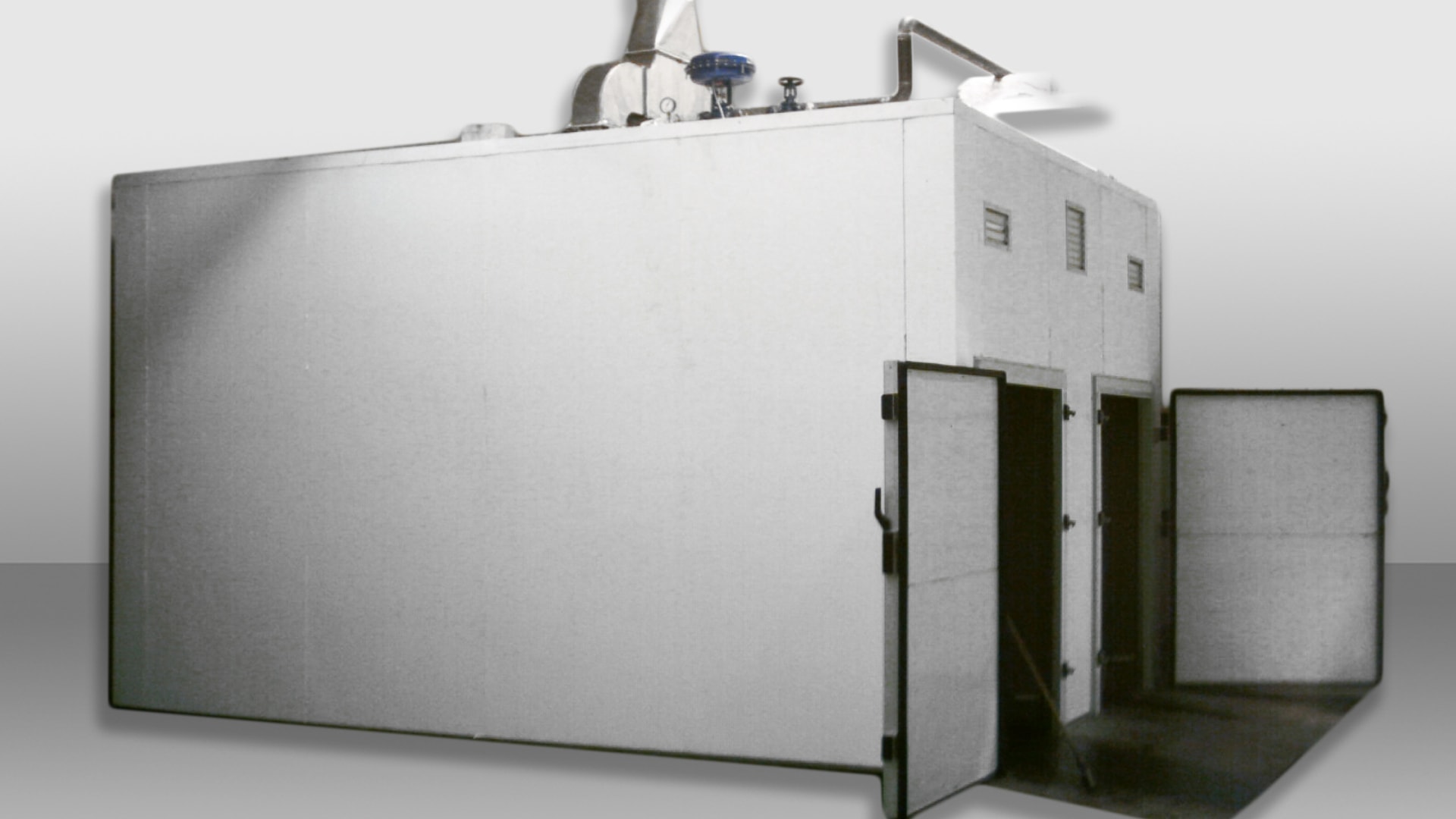

Traydry-LXC

-

Industries:

- Vegetables

Benefits

Increases production capacity with 3 to 5 sections for rapid, continuous drying.

Three models adapt to varying capacities, ensuring versatility in drying applications.

Medium to high-capacity dryer optimizes energy use, guarateeing sustainable and cost-effective operations.

Features

Features

- Ease of washing optimizes maintenance, ensuring impeccable hygienic conditions

- Gentle low temperature heat treatment preserves the quality of products during the drying process

- Designed for sticky products, the design minimizes sticking for an efficient and smooth drying process

Mecdry MD

-

Industries:

- Fruits

- Vegetables

Benefits

High-speed heat treatment and independently regulated stages ensure effective drying for optimal fruit and vegetable quality.

The modular design and adjustable speed maximize productivity, improving overall drying efficiency.

Low energy consumption thanks to isolated belt connection sections and exhaust air humidity control.

No possibility of product contamination thanks to the lubrication-free conveyor system.

Features

Features

- High mechanical reliability of the conveyor

- Proprietary software for automatic belt tension adjustment

- Heating power from 500 to 7,000 kW

- Ideal for high-moisture plant products

Dosaform

-

Industries:

- Vegetables

-

Min. Capacity:

- 3,500 Kg/h

-

Max Capacity:

- 5,000 Kg/h

Benefits

3 functions in a single and compact machine: dewatering, portioning and cutting.

Designed for easy wash-up thanks to complete and easy opening.

The machine can adjust the forming speed and pressure according to product needs.

Features

Features

- State-of-the-art self-adjusting cutting system with minimal wear for enhanced performance

- Precision control of forming pressure through electronic systems for optimal and consistent results

- Gentle piston feeder designed to minimize damage to leaves, ensuring delicate handling of the material

- High-speed hydraulic pistons

Aquasort

-

Industries:

- Vegetables

-

Min. Capacity:

- 2,000 Kg/h

-

Max Capacity:

- 6,000 Kg/h

Benefits

Aquasort ensures accurate leaf vegetable separation, enhancing product quality and market appeal.

Swift cooling post-sorting preserves freshness, extending shelf life for improved product longevity.

Aquasort minimizes water usage during the process, promoting sustainability and reducing environmental impact.

Features

Features

- Achieving efficient dispersion of blanched leaves within a water flow to guarantee uniform cooling

- A precise inspection facilitated by a thin layer of leaves on the sorting belt

- Maximum operational efficiency, designed to maximize efficiency when processing leafy greens

- Ease of maintenance with components designed for easy servicing, ensuring continuous plant operation

Airseparators

-

Industries:

- Vegetables

-

Min. Capacity:

- 2,000 Kg/h

-

Max Capacity:

- 6,000 Kg/h

Benefits

Streamlined leaf separation, ensuring top-quality produce for further processing.

Rapid automated sorting, reducing labor costs and handling large vegetable volumes.

Consistent, accurate sorting enhances product quality and meets industry standards.

Features

Features

- Leaf grading based on size

- “Single leaf” product dispersion

- Aerodynamic selection (based on product shape)

No machine found. Please use fewer filters.