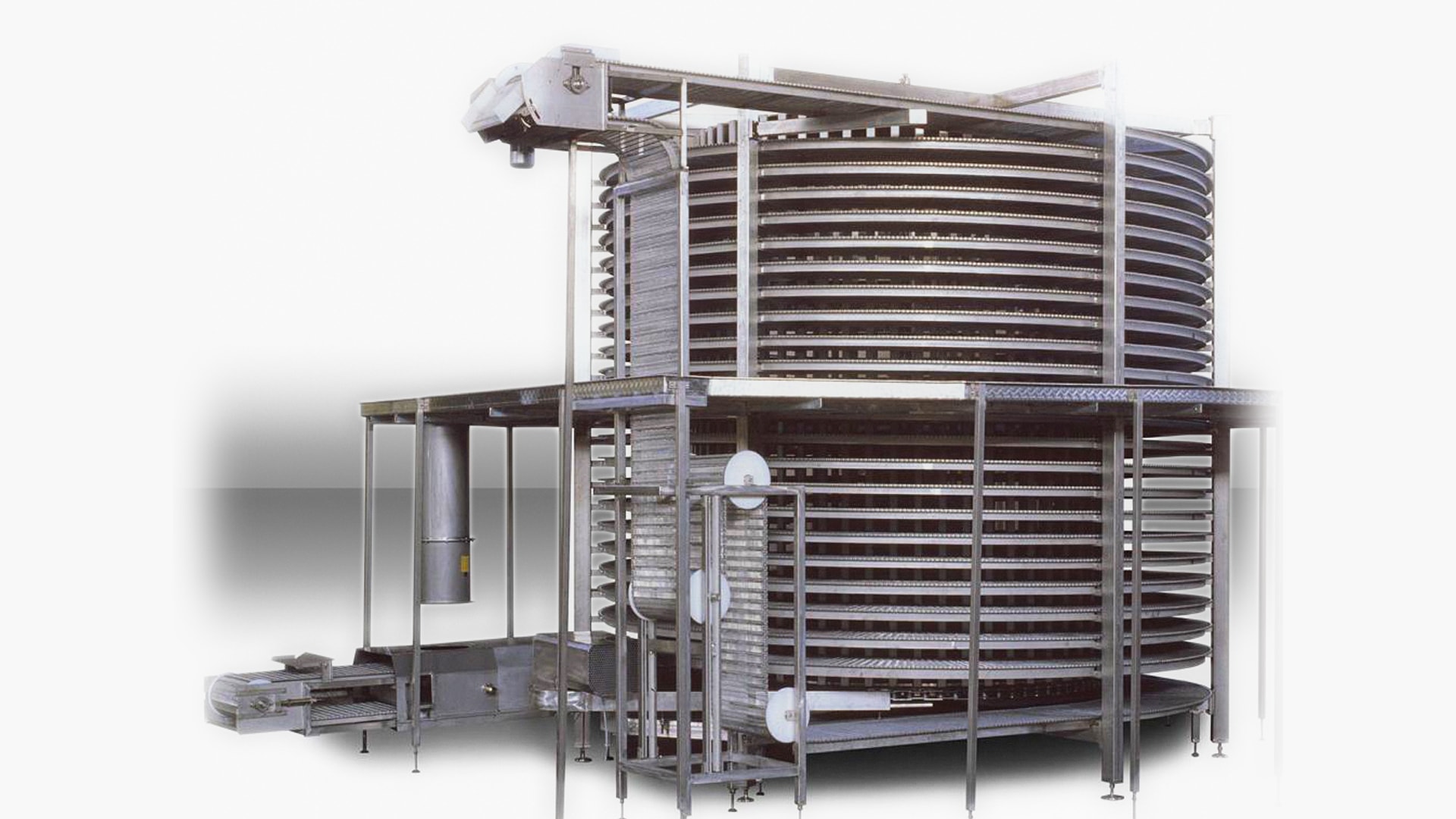

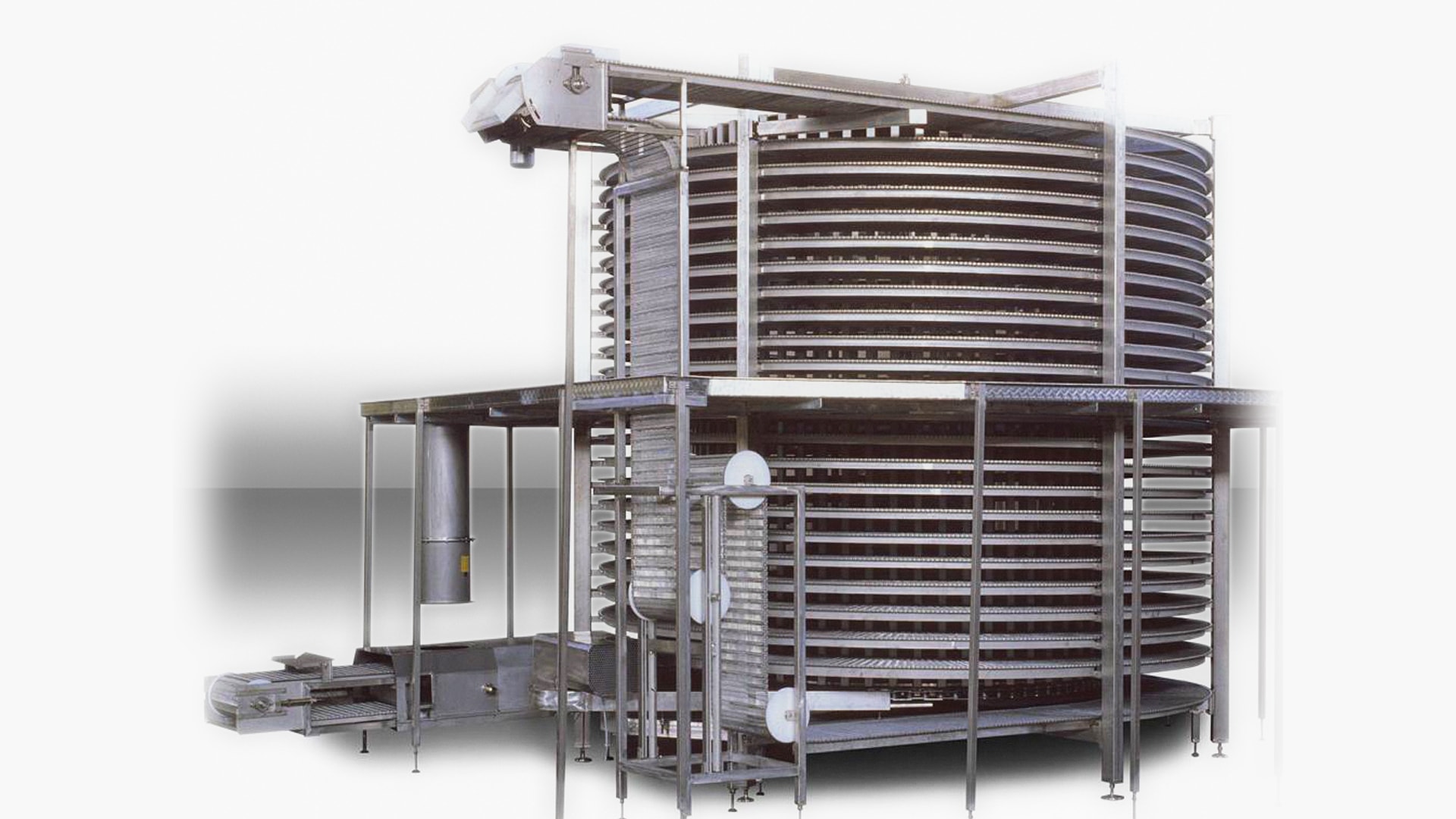

Spiral systems

Wide range of spirals capable of handling different packaged or loose food products.

Our range of spirals pasteurize, cool, refrigerate, cook and dry various food products. Each system is customizable to meet the customer’s technical specifications.

Spirafreeze

-

Industries:

- Fruits

- Ketchup, Sauces, Jams

- Vegetables

-

Technology:

- Air

Benefits

Ensures uniform freezing, maintaining product quality reducing human error.

Boosts production efficiency by eliminating the need for constant monitoring and intervention.

Reduces labor costs and increases operational cost-effectiveness.

Features

Features

- Enhance operations with a reliable spiral conveyor, minimizing downtime for increased overall efficiency

- Extended belt lifespan, optimal performance, enhancing conveyor system efficiency and cost-effectiveness

- Low cost of spare parts and maintenance activities due to high quality components

Mecspray MS-R/P

-

Industries:

- Beverage

- Ketchup, Sauces, Jams

- Other Foods

- Tomato

- Vegetables

-

Min. Capacity:

- 400 Kg/ora

-

Max Capacity:

- 10,000 Kg/ora

-

Technology:

- Water

Benefits

A water recovery and circulation system ensures limited water consumption.

No possibility of product contamination due to the lubrication-free conveyor system.

High mechanical reliability and stability of the spiral conveyor.

Increased heat exchange/production and reduced power consumption thanks to proprietary design of special nozzles for product agitation.

Features

Features

- Stainless steel structures for all water piping and spiral components, including the drum

- Proprietary software for automatic adjustment of belt tension, avoiding tipping

- Reduced belt wear and elongation due to low-tensioned drive system

- Adjustment of the dwell time/speed of the belt by means of variable frequency drives

Mecair MA-C Spiral Cookers

-

Industries:

- Ketchup, Sauces, Jams

- Tomato

- Vegetables

-

Min. Capacity:

- 400 Kg/ora

-

Max Capacity:

- 2,000 Kg/ora

-

Technology:

- Air

Benefits

No possibility of product contamination due to the lubrication-free conveyor system.

High mechanical reliability and stability of the spiral conveyor.

Thanks to a special horizontal air circulation system that ensures temperature uniformity on all the lanes of the belt.

The fast and uniform air/steam flow ensures effective cooking, preserving the quality of the product.

Features

Features

- Reduced belt wear and elongation due to low-tensioning drive system

- Proprietary software for automatic belt tension adjustment

- All spiral structures, including the drum, are made of stainless steel

- Cooking through direct injection of steam or dry hot air

- Customizable configuration

Mecair MA-R/P

-

Industries:

- Ketchup, Sauces, Jams

- Other Foods

- Tomato

- Vegetables

-

Min. Capacity:

- 400 Kg/ora

-

Max Capacity:

- 3,000 Kg/ora

-

Technology:

- Air

Benefits

The fast and uniform airflow ensures effective cooling/pasteurization, preserving the quality of the product.

High mechanical reliability and stability of the spiral conveyor.

Low power consumption due to horizontal airflow and evaporators with very wide fin spacing (coolers).

No possibility of product contamination thanks to the lubrication-free conveyor system.

Features

Features

- Reduced belt wear and elongation due to low-tensioning drive system

- Proprietary software for automatic belt tension adjustment

- All spiral structures, including the drum, are made of stainless steel

- Circulation fans positioned in a dry area to minimize clogging (coolers)

- Long operating cycles due to evaporators with wide and decreasing fin spacing

No machine found. Please use fewer filters.