Aseptic fillers

This range of machines combines advanced technology with absolute sterilization in the packaging process.

With more than 300 aseptic fillers installed worldwide and more than 4 million bags filled, we are experienced and reliable suppliers.

Minipak

-

Industries:

- Fruits

- Milk & Dairy

- Tomato

-

Min. Capacity:

- 5 liters/bag

-

Max Capacity:

- 20 liters/bag

-

Container:

- Bags

Benefits

Highly flexible by allowing the use of a wide variety of closures currently available on the market.

Up to 500 bags per hour with low viscosity products.

Reduced footprint suitable for small-medium workshops.

Features

Features

- Speed up to 500 bags per hour with low viscosity products

- Filler suitable for small bags: 5-20 kg (11-44 lb)

- 1” integral passage dosing device for liquid or viscous foods and for products containing fibers or pieces

- Washing of the filling spout through steamjet/condensate

- Optional FDA validation test

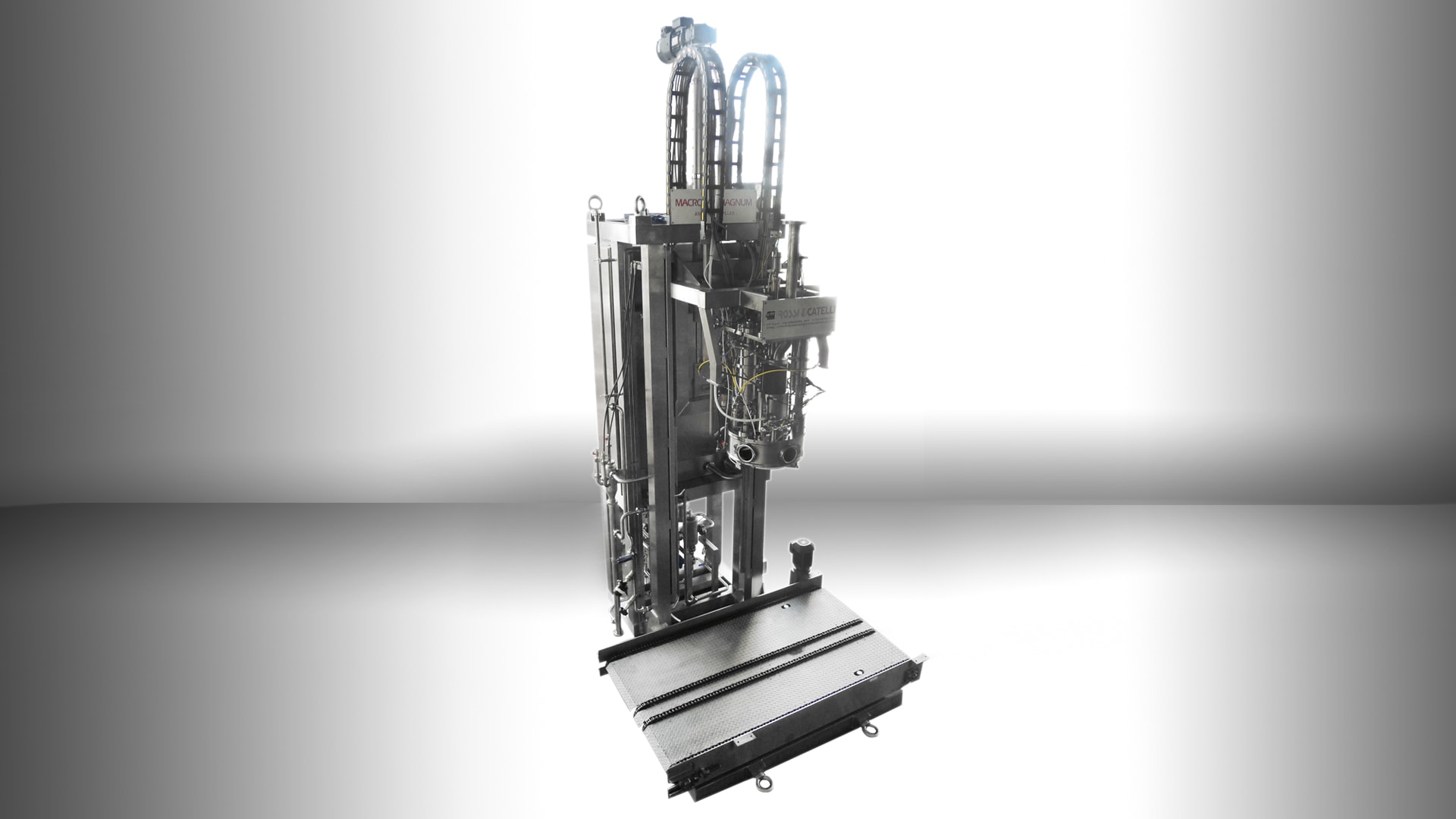

Aseptic Magnum

-

Industries:

- Milk & Dairy

- Tomato

-

Max Capacity:

- 1,000 liters/bag

-

Container:

- Bags

Benefits

Automatic control of the pressure exerted by the product in the bag.

The head translation from the bottom to the top of the container allows perfect filling of viscous products.

Remote monitoring system via VPN.

Features

Features

- 3” (inch) integral passage dosing device suitable for very viscous or fibrous products

- Filling of 4 drums on pallet with automatic translation and rotation through inverter

- Dosing device with axial seal system designed for products containing fibres

Macropak RVS

-

Industries:

- Fruits

- Tomato

- Vegetables

-

Min. Capacity:

- 5 liters/bag

-

Max Capacity:

- 200 liters/bag

-

Container:

- Bags

Benefits

Choose from small bags to drum bags, with various spout options.

The 2'' (inch) passage dosing device handles high flow rates, different viscous products, fibers and various formulations.

Steam washing and oil-free filling ensure a hygienic process.

Accurate weight control with load cells ensures consistent filling for quality and compliance.

Features

Features

- Filling head translation system through pneumatic cylinder

- Dosing device with axial seal system designed for products containing fibres

- Array

- Remote monitoring system via VPN

- FDA validation test

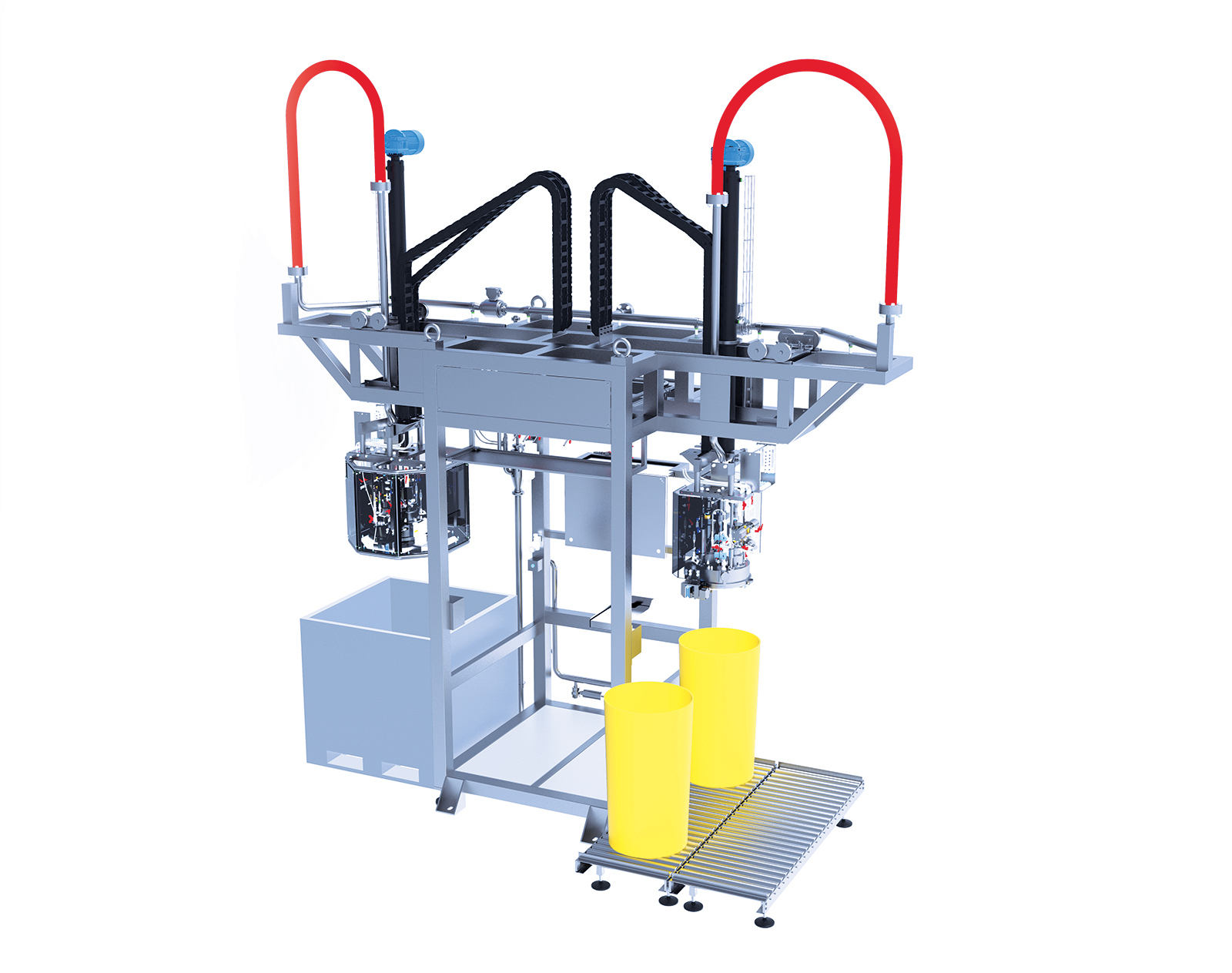

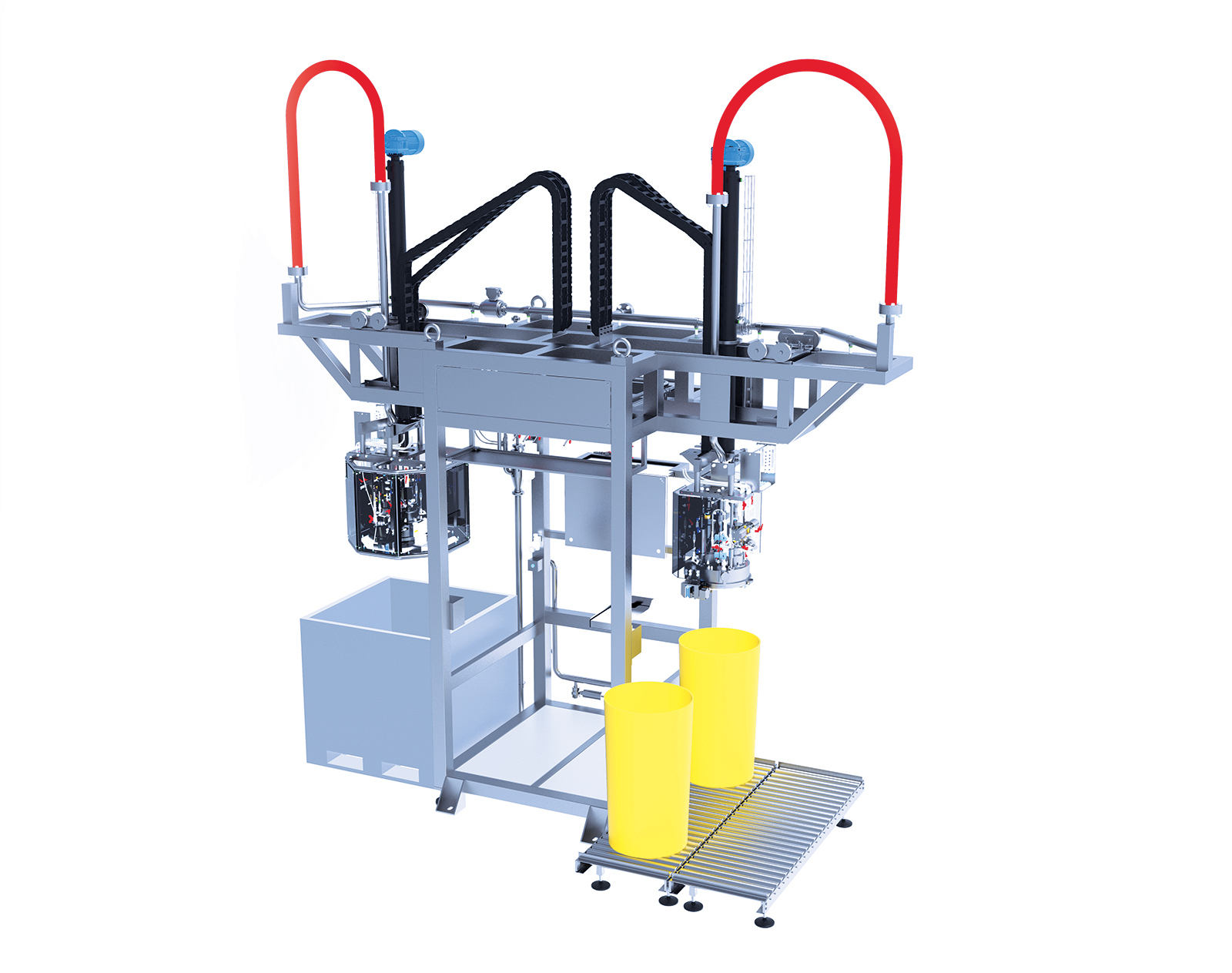

Macropak MF

-

Industries:

- Fruits

- Milk & Dairy

- Tomato

- Vegetables

-

Min. Capacity:

- 5 liters/bag

-

Max Capacity:

- 200 liters/bag

-

Container:

- Bags

Benefits

Choose from small bags to drum bags, with various spout options.

The 2'' (inch) passage dosing device handles high flow rates, different viscous products, fibers and various formulations.

Ensures aseptic conditions with spout washing through steam, maintaining product integrity.

Utilizes magnetic flowmeter for accurate dosing, enhancing overall process precision.

Features

Features

- Pressure control during filling

- Dosing device with axial seal system designed for products containing fibres

- Optional 1,000 L bags for bins

- Remote monitoring system via VPN

- FDA validation test

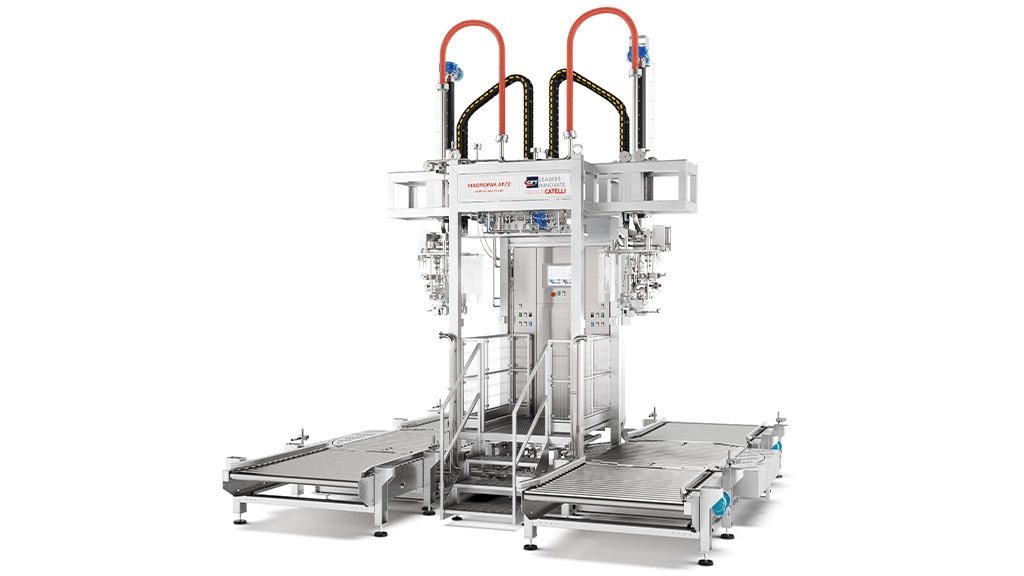

Macropak AF

-

Industries:

- Fruits

- Tomato

- Vegetables

-

Min. Capacity:

- 200 liters/bag

-

Max Capacity:

- 1,000 liters/bag

-

Container:

- Bags

Benefits

Adaptability to fill 3 different packaging formats, such as aseptic bags in bins, drums and pouches.

The 2'' (inch) passage dosing device handles high flow rates, different viscous products and fibers with ease.

Steam washing and oil-free filling ensure a hygienic process.

Accurate weight control with load cells ensures consistent filling for quality and compliance.

Features

Features

- Two-head design for efficient and versatile aseptic filling

- This model is also available with a single head (AF/1)

- Versatile for liquids, semi-liquids, highly viscous substances, and particulate-laden products

- 1,000 liters aseptic bags in bin, 200 liters aseptic bag in drums, 5-20 liters aseptic pouches

- Optional web fed kit for aseptic filling of 5L, 10L, or 20L pouches

- FDA validation test

Labopak

-

Industries:

- Fruits

- Tomato

- Vegetables

-

Min. Capacity:

- 5 liters/bag

-

Max Capacity:

- 20 liters/bag

-

Container:

- Bags

Benefits

Unmatched quality and performance at a competitive price.

High-level automation and process control ensure product consistency.

Cost-effective and low-maintenance equipment.

Features

Features

- Handles liquid, viscous, and particulate products with pH < 45

- Filler designed for 5-20 liter aseptic bags

- Optional magnetic or mass flowmeter for dosing

- Optional kit for filling products with ph > 4,5

No machine found. Please use fewer filters.