Robotic handling

Custom-engineered robotic handling systems for trays, bins, kegs or other containers.

These robots can be programmed to be easily combined with complete processing or packaging lines in the fruit, vegetables and beverage industries.

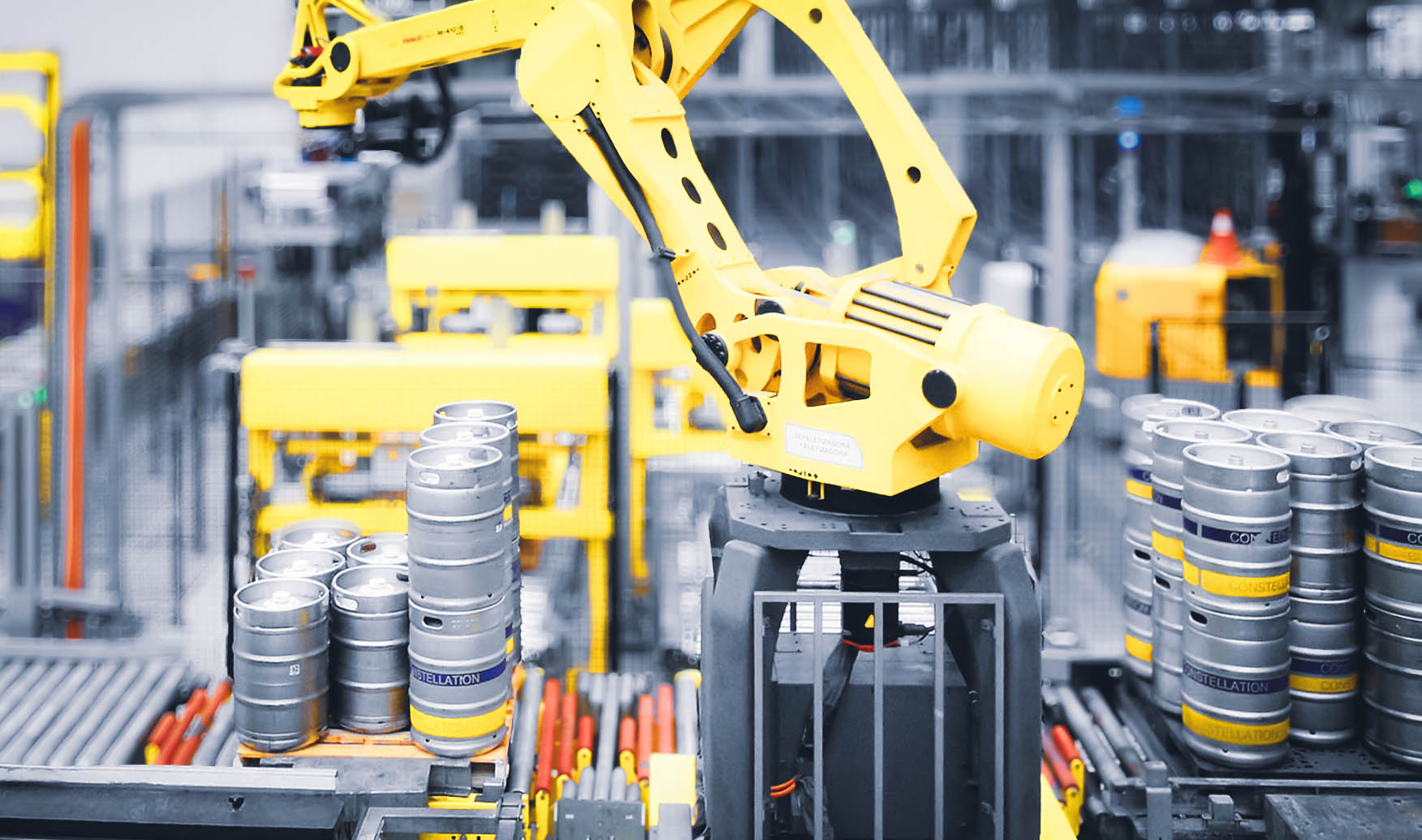

Robokeg

-

Industries:

- Beverage

- Ketchup & Mayonnaise

-

Max Capacity:

- 360 containers/hour

-

Container:

- Kegs

Benefits

The robot can be customized according to the line configuration and desired output.

Equipped with reliable components made by international brands, easy to install and replace in case of need.

Robots streamline keg handling, increasing overall efficiency in beverage manufacturing.

Automated keg handling by robots enhances workplace safety by minimizing manual lifting and movement.

Features

Features

- Automatic keg’s recognition system with 3d vision module

- Latest generation HMI module for system monitoring and configuration

- The handling grippers designed by CFT are universal for all kegs: no format change is necessary on the robot

- 6 axis robot

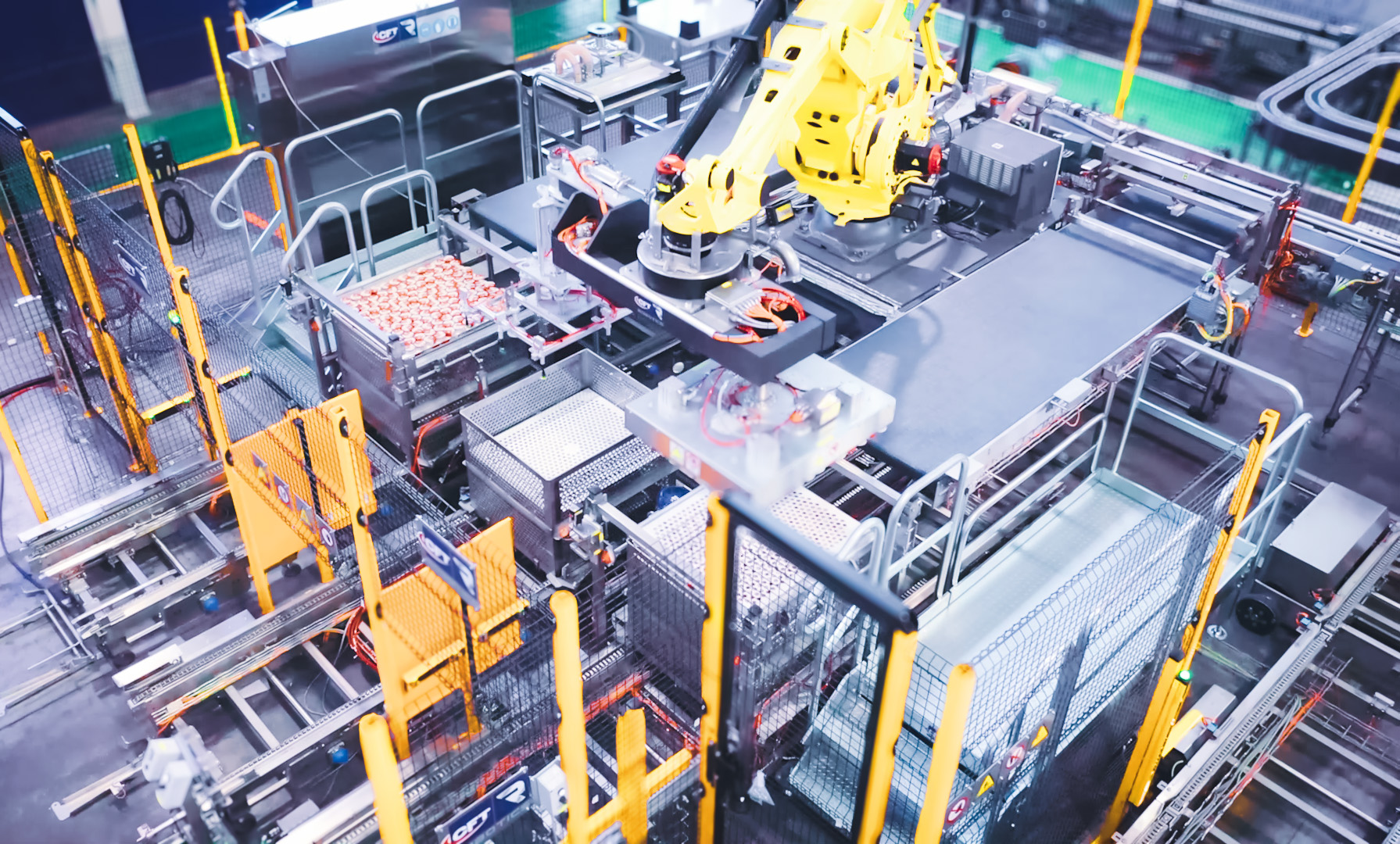

Loading/Unloading Robots

-

Industries:

- Baby Food

- Beverage

- Other Foods

- Pasta sauces

- Tomato

- Vegetables

-

Max Capacity:

- 160 containers/hour

-

Container:

- Cans

- Jars (Glass)

- Pouches

- Tin plates

Benefits

With advanced sensors and programming, these robots can handle delicate items with precision, minimizing the risk of damage.

Suitable for different kind of formats, these robots can be a smart solution for a Food, Pet Food or Beverage production line.

Equipped with reliable components made by international brands, easy to install and replace in case of need.

Suitable for a wide variety of packaging formats.

Features

Features

- Widely used in production lines that require autoclave sterilization

- Customized vacuum gripper

- 4 axis robot

Bins Dumper

-

Industries:

- Fruits

- Tomato

- Vegetables

-

Max Capacity:

- 80 containers/hour

-

Container:

- Bins

Benefits

The robot can feed multiple receiving tanks, based on specific recipe instructions.

Self-adjusting gripper based on the container dimensions.

Up to four bins can be stacked to optimize line feed.

Features

Features

- Line efficiency guaranteed by a constant supply of product

- Self-adapting gripping tool designed by CFT

- Effective handling with all types of bins with triple system including lifting forks and lateral and vertical pressers

- Payload: up to 1,000 kg

- 6 axis robot

No machine found. Please use fewer filters.