Sterilizers and Pasteurizers

Explore our range of sterilizers and pasteurizers with different technologies adapting to specific products.

Our sterilizers offer various technologies, some of which are patented, suitable for specific application sectors (such as liquid or semi-liquid foods and viscous foods).

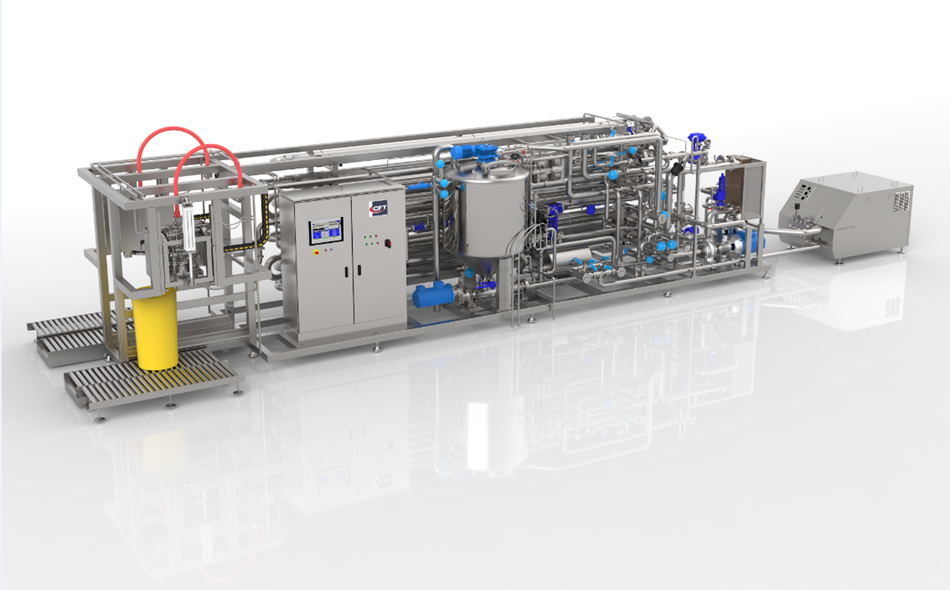

Stematic Long Run

-

Industries:

- Milk & Dairy

-

Max Capacity:

- 40,000 Kg/h

-

Technology:

- Heat exchanger

Benefits

The organoleptic characteristics of the product are perfecly preserved.

The machine can also process very viscous products such as creams and bechamel.

Products can be heated up to over 150 ° C

Features

Features

- Ability to reach very high temperature (over 150°c)

- Ability to process viscous product

- Short product residence time at the sterilization temperature

Olimpic TC

-

Industries:

- Ketchup, Sauces, Jams

- Tomato

-

Viscosity:

- High Viscosity

-

Min. Capacity:

- 4,000 Kg/h

-

Max Capacity:

- 16,000 Kg/h

-

Technology:

- Heat exchanger

Benefits

The revolutionary patented heat exchanger ensures hygienic design eliminating stress from thermal expansion.

Easy and fast maintenance, with no need for the full extraction of the inner bundle.

Washing times are short, thanks to an integrated backflush mechanism implemented in the cycle.

Features

Features

- Maximum thermal exchange efficiency

- Process uniformity

- Product viscosity up to 10,000 cp

Olimpic SR

-

Industries:

- Fruit

- Ketchup, Sauces, Jams

- Tomato

- Vegetables

-

Viscosity:

- High Viscosity

-

Min. Capacity:

- 5,000 L/h

-

Max Capacity:

- 40,000 Kg/h

-

Technology:

- Heat exchanger

Benefits

Hygienically designed in accordance with 3-a sanitary standards.

Sterilizer frame outfitted with two hoists for streamlined maintenance of seals and blades.

The Olimpic SR series provides reliable mechanical heat transfer, ensuring durability in food processing.

Ideal for challenging food products, ensuring thorough pasteurization and sterilization.

Features

Features

- Product viscosity: from 100 to 20,000 cp

- Product pressure: up to 20 bar

- Automatic cycle for descaling heat exchangers water jackets

- Different sizes available, with exchange surface: from 0.86m2 up to 1.5 m2

Olimpic P Plates

-

Industries:

- Beverage

- Milk & Dairy

-

Viscosity:

- Low Viscosity

-

Min. Capacity:

- 5,000 L/h

-

Max Capacity:

- 40,000 Kg/h

-

Technology:

- Heat exchanger

Benefits

Swift preheating, pasteurization, and cooling for liquid products, optimizing production timelines.

Plate heat exchanger ensures precise temperature control, preserving taste and nutritional value.

Maximum thermal exchange efficiency and process uniformity.

Features

Features

- High modularity / expandability

- Maximum thermal exchange efficiency

- Process uniformity

Olimpic FT

-

Industries:

- Beverage

- Ketchup, Sauces, Jams

- Milk & Dairy

-

Viscosity:

- Low Viscosity

-

Min. Capacity:

- 4,000 Kg/h

-

Max Capacity:

- 24,000 Kg/h

-

Technology:

- Heat exchanger

Benefits

Ensures aseptic sterilization, safeguarding low and medium viscosity food products from contaminants.

Energy savings, up to 80%, are achieved through an intermediate loop system (product/water/product) or product-to-product tubular exchangers.

Washing times are short, thanks to an integrated backflush mechanism implemented in the cycle.

Features

Features

- The special design reduces product losses from the water/product interface, enhancing cost-effectiveness and resource efficiency

- Use of positive displacement pumps for mass transfer

- Combination with all the CFT aseptic fillers. or with CFT piston fillers in pasteurizer version

Olimpic Cube

-

Industries:

- Fruit

- Ketchup, Sauces, Jams

- Tomato

- Vegetables

-

Viscosity:

- High Viscosity

-

Min. Capacity:

- 1,000 Kg/h

-

Max Capacity:

- 10,000 Kg/h

-

Container:

- Bags

-

Technology:

- Heat exchanger

Benefits

Revolutionary patented heat exchanger technology ensures a hygienic design, eliminates stress from thermal expansion, and enables complete drainability.

Versatile processing capabilities extend to a wide range of products, with a special emphasis on efficiently handling highly viscous substances.

Cutting washing times with an integrated backflush mechanism in the cycle.

Features

Features

- Able to fill 220-liter bags through 1-inch or 2-inch spouts

- Able to fill from 5 up to 20 kg bags through optional kit

- The technology reduces stress from thermal expansion, enhancing equipment durability

- The design promotes complete drainage, reducing contamination risks and enhancing cleaning efficiency

Ohmic Sterilizer

-

Industries:

- Fruit

- Ketchup, Sauces, Jams

- Vegetables

-

Viscosity:

- Low & High Viscosity

-

Min. Capacity:

- 500 Kg/h

-

Max Capacity:

- 12,000 Kg/h

-

Technology:

- Electricity

Benefits

Sterilization through electricity provides efficient and fast heating and cost savings.

Preservation of food colour, taste and texture

implying fast product heating (6°C/s)

Features

Features

- High modularity / expandability

- Empower operators with an intuitive system for efficient parameter control, enhancing user experience

- Heats any food type effortlessly, showcasing an unmatched versatility

Aseptic Flash Cooler

-

Industries:

- Tomato

-

Viscosity:

- High Viscosity

-

Max Capacity:

- 40,000 Kg/h

Benefits

Exceptional efficiency with up to 40,000 kg/h in processing capacity, ensuring rapid production for your operations.

Rapid sterilization and cooling ensure the integrity of dense high-flow food products.

Optimized design reduces energy consumption, enhancing sustainability while delivering efficient treatment.

Features

Features

- Versatile processing handles high viscosity, Bostwick value < 2

- Extended cycles surpass other sterilizers, ensuring unmatched reliability in production

- Automatic flow control in the buffer tank ensures stability and reduces interruptions

- Complete process monitoring with the ability to record data

No machine found. Please use fewer filters.