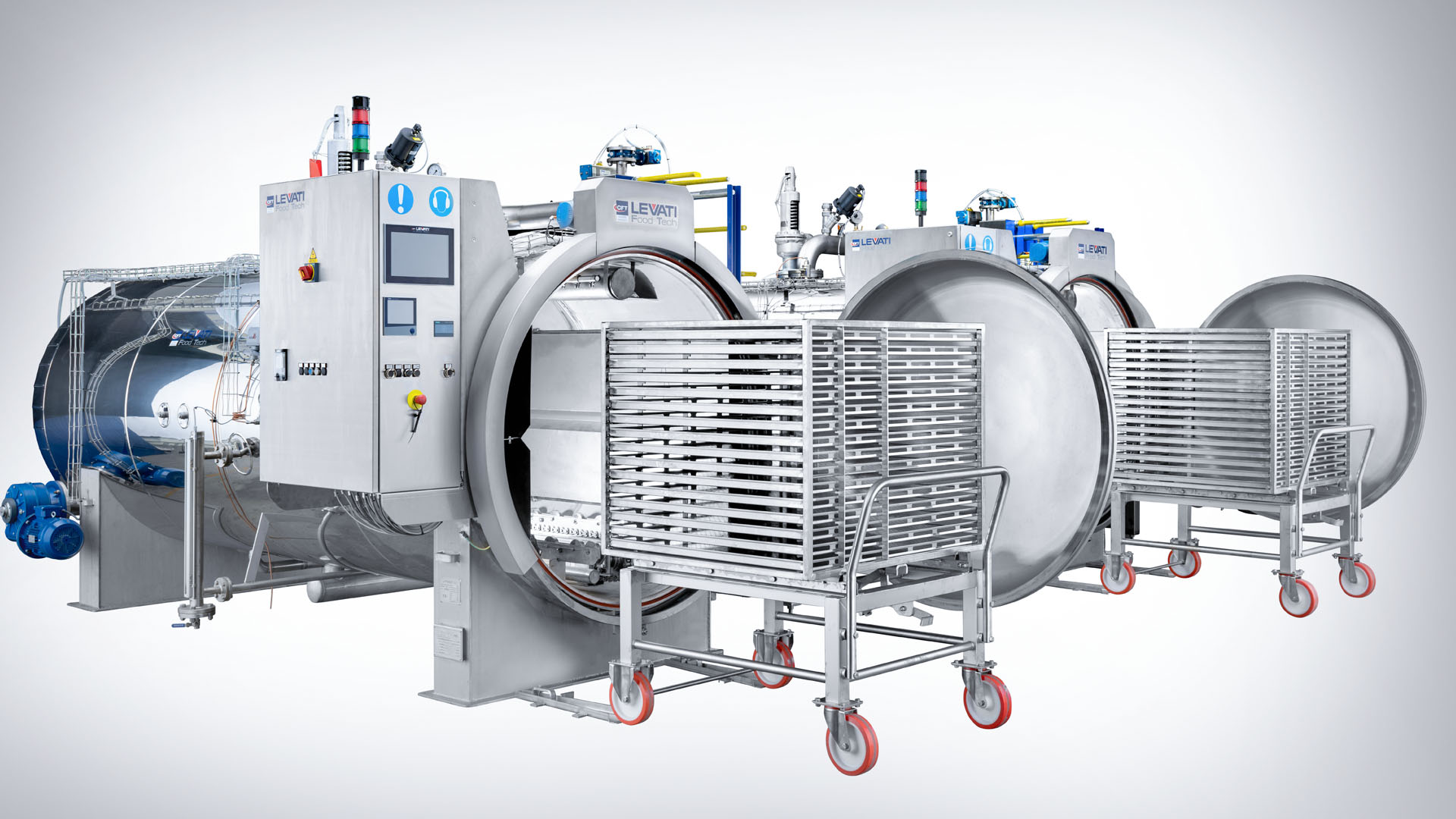

Batch retorts

Retorts for optimal sterilization and pasteurization of packaged foods.

We design a wide range of sterilization retort models to meet the highest food industry performances standards in terms of package integrity and respect of the organoleptic properties of the products.

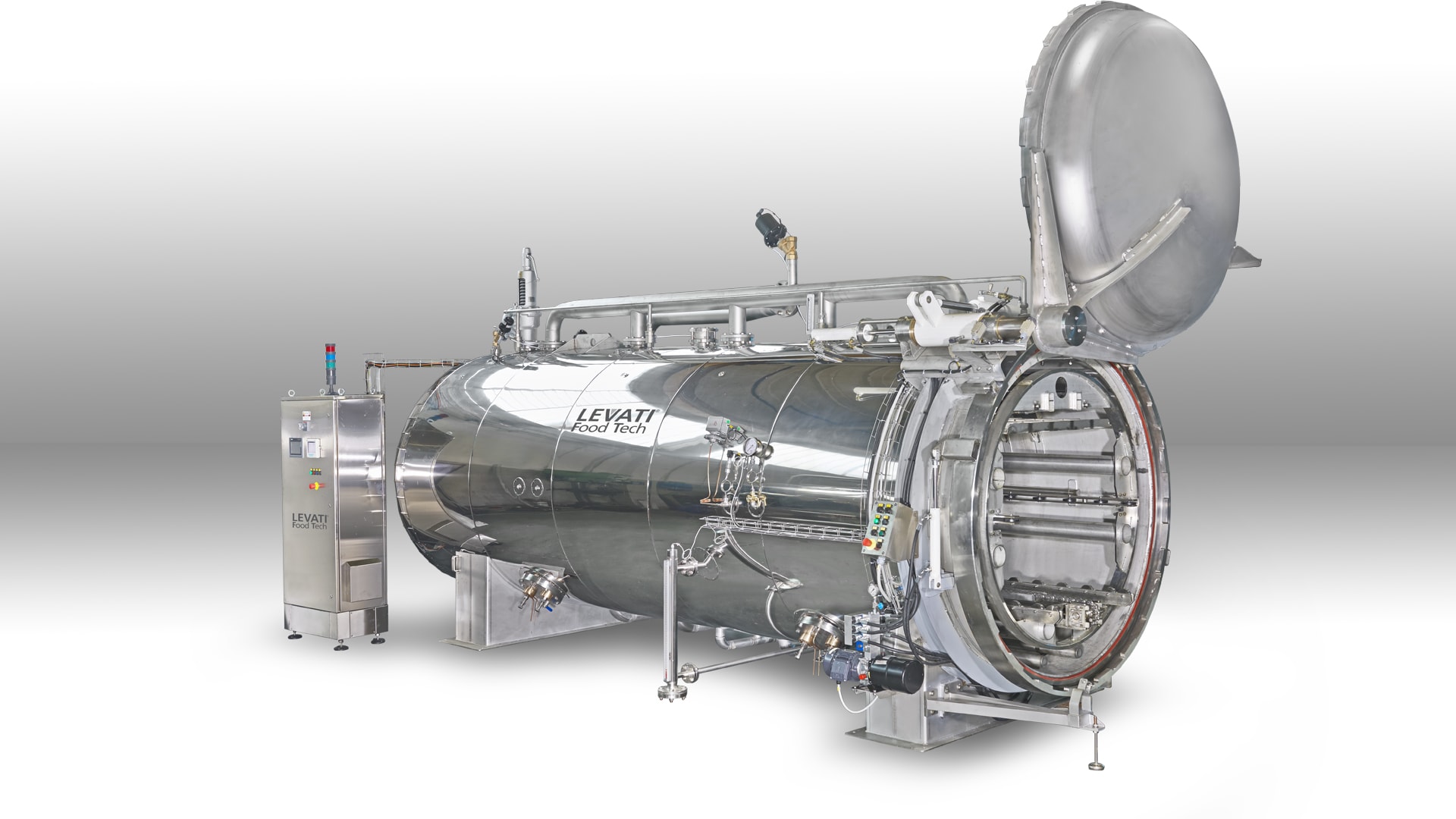

Prima Static Retort

-

Industries:

- Beverage

- Ketchup, Sauces, Jams

- Tomato

- Vegetables

-

Container:

- Cans

- Pouches

Benefits

This static retort can sterilize with saturated steam, water rain or steam air technologies.

No need for any hydraulic supply unit or oil pressure.

Highest operator safety and reduced wear and tear on main door seal.

Features

Features

- Steam, air and cooling water pipes constructed of stainless steel and located inside the retort

- Long gaskets duration thanks to the special locking system

- Non-return valves on air-steam-water inlets

Prima rotary retort

-

Industries:

- Beverage

- Ketchup, Sauces, Jams

- Tomato

- Vegetables

-

Container:

- Cans

- Pouches

- Trays

Benefits

No need for any hydraulic supply unit or oil pressure.

Accommodates to various sizes/types of containers, enhancing processing flexibility.

Uniform thermal heat distribution reduces sterilization time, significantly enhancing product quality.

The locking system ensures consistent pressure distribution around the door, unlike traditional systems that apply pressure to only 50% of the door's circumference.

Features

Features

- Modulated water rain cycle

- The locking system prevents external ring from seizing by eliminating rotation on the other two rings to lock and unlock the door

- Extended door gasket lifespan ensured by the complete absence of door rotation

No machine found. Please use fewer filters.