Tomato processing line in Egypt

Together with Karry Food, we set a new benchmark

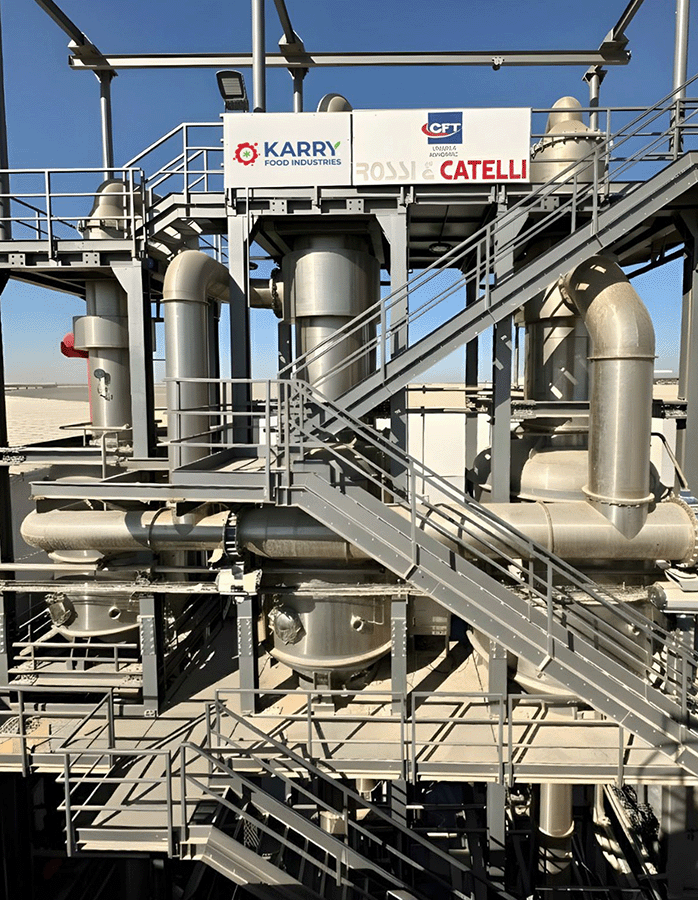

When in 2023 Karry Food Industries selected us to build its first tomato processing line, a partnership with unique potential was born—one destined to become a benchmark for the entire Egyptian market. A shared vision based on quality, high standards, and international ambition guided every phase of the project.

Today, this partnership reaches a new milestone: the second tomato processing line is officially up and running, introducing an unprecedented level of technology in terms of production capacity, performance, and process flexibility.

New national standard in tomato processing

With the start-up of the second line, Karry Food achieves a major production milestone for the Egyptian industry: 1,200 tons/day, the highest installed capacity currently operating in the country. This result raises the competitive bar across the sector and further strengthens the company’s position in the market.

We designed the line to deliver maximum flexibility while ensuring high performance, enabling the production of a wide range of products: from 10 Brix up to 36–38 Brix, including pizza sauce and high-Brix (HB) concentrates at 28–30 and 30–32 Brix. In every configuration, the plant guarantees excellent standards of color, consistency, and taste, keeping final product quality at the core of the process.

Our technology at the heart of the process

The tomato processing line integrates some of the most advanced solutions from the CFT portfolio, engineered to ensure maximum efficiency, operational reliability, and total hygiene throughout the entire production process. Advanced technologies working in synergy make tomato processing stable, controlled, and high-performing.

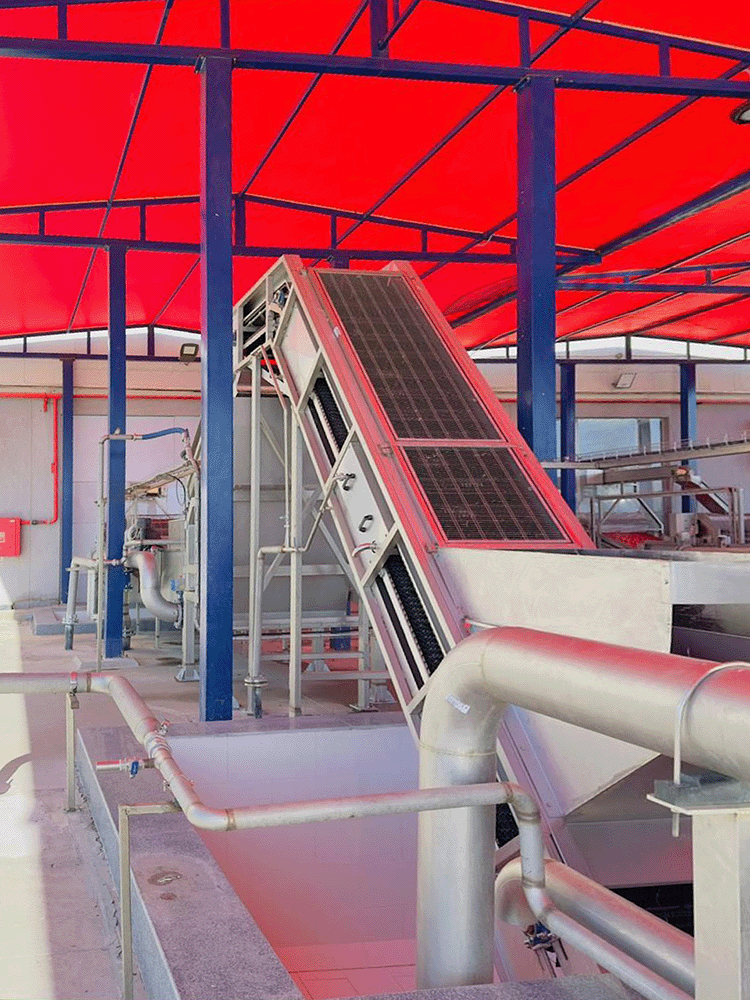

1. High-performance washing

-

- Double washing tanks equipped with two closed-loop filtration circuits

- Deep raw material cleaning, process continuity, and waste reduction

This initial stage configuration ensures optimal treatment of fresh product, supporting consistent quality right from the line intake.

2. Enzymatic inactivation and extraction – Eldorado and Giubileo

-

- Immediate enzymatic inactivation through the Eldorado inactivator

- Yield up to 98% thanks to the Giubileo extractor and refiner

- Bostwick value of 1.7 at 100°C

The stability and precision of this process eliminate the risk of burn-on and enable the production of superior-quality juice and pulp: higher viscosity, uniform structure, and a bright, vivid color.

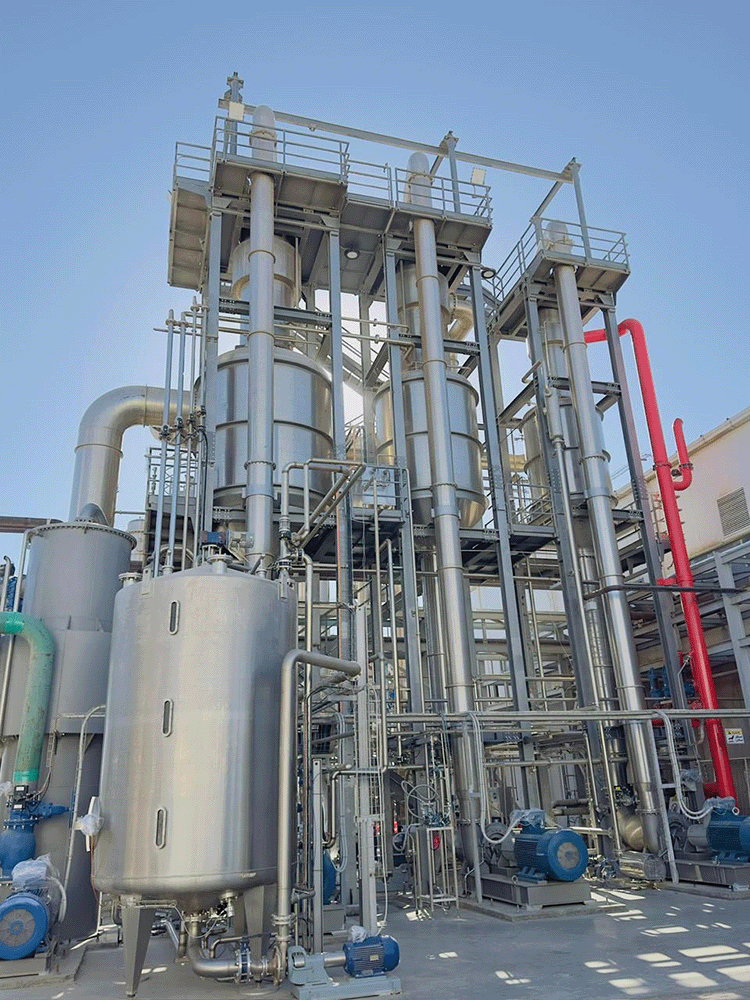

3. Evaporation – Venus: high performance even with high-viscosity products

-

- Innovative heat exchanger design, ideal for high-viscosity products

- Maximum color preservation and precise achievement of target Brix values

- No burn-on or fouling thanks to Rossi & Catelli circulation pumps

The Venus evaporator proves to be extremely efficient even under the most demanding operating conditions.

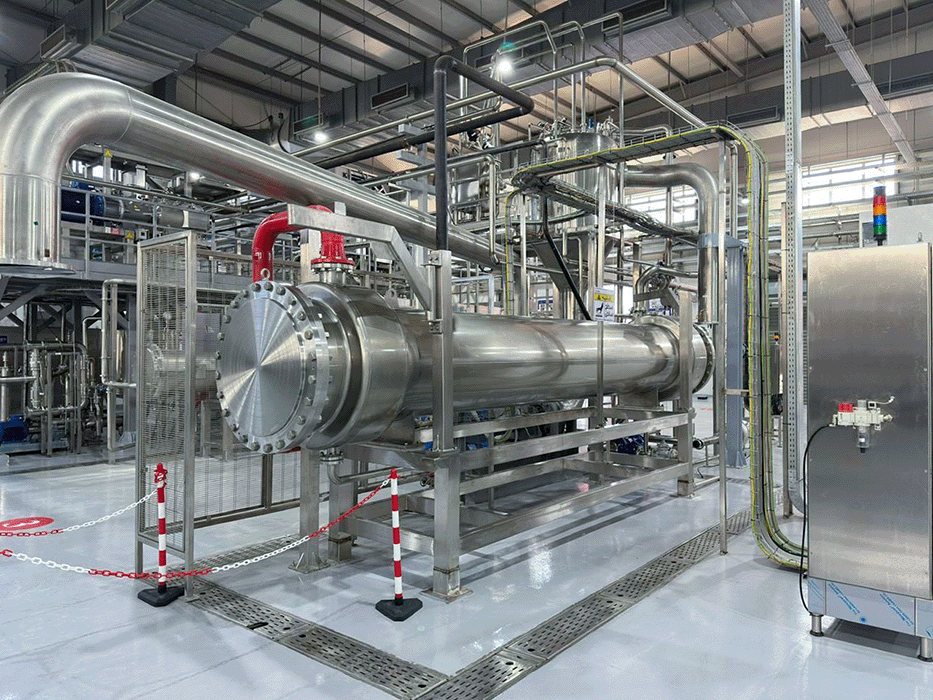

4. Sterilization – Olimpic TC

-

- Sterilizer with CFT patented ogive flange for high heat transfer coefficients and simplified maintenance

- Elimination of black spot risk

- Fully hygienic sterilization for a safe, high-quality final product

Thanks to the integration of these technologies, the plant becomes a new reference point for the Egyptian tomato industry, paving the way for more modern production and redefining market expectations. As stated by the customer itself: “A milestone achieved. A new standard set.”

The third line: from tomato processing to the retail market

The success of the second line has provided a decisive boost to Karry Food’s industrial development.

We are now engaged in the design of a third line dedicated to concentrate reprocessing and packaging in glass jars and cans for products such as tomato paste and ketchup.

This new line represents a highly strategic step: it will enable Karry Food to enter the B2C market with the launch of a new brand, complementing its industrial business with a competitive, high–added-value retail offering.

Digital Tomato™: the future integrated monitoring platform

With two processing lines and two packaging lines in operation, the next step will be the full digitalization of plant supervision. Our Digital Tomato™ platform will allow Karry Food to:

- Monitor production parameters in real time

- Optimize yields and consumption

- Prevent downtime through predictive maintenance

- Integrate all lines into a single intelligent control ecosystem

An evolution that will drive the plant toward a more data-driven management approach, transforming it into a true smart tomato factory.

One partner, from field to shelf

The Karry Food story demonstrates our value as a partner: a single point of reference capable of supporting the company across the entire supply chain—from raw material reception to Cold Break and Hot Break processes, from high-efficiency evaporation to sterilization and aseptic filling, all the way to recipe development, industrial kitchens, filling, and packaging for the retail market. Every stage benefits from advanced automation, supervision, and digitalization solutions.

Our collaboration with Karry Food is not merely technical, but a long-term strategic project. With the start-up of the second line and the future installation of the third, a center of production excellence is taking shape—one that will support Karry Food’s evolution from B2B to B2C and strengthen the positioning of Egyptian tomatoes on international markets.

A growth journey that we are proud to support with complete, integrated, and future-oriented solutions.