Choppers, Extractors, Refiners

Our range boasts some patented technologies, which enable the highest level of extraction and refining.

Our extraction technologies and enzymatic inactivation offer a yield and quality that distinguish our customers in the market.

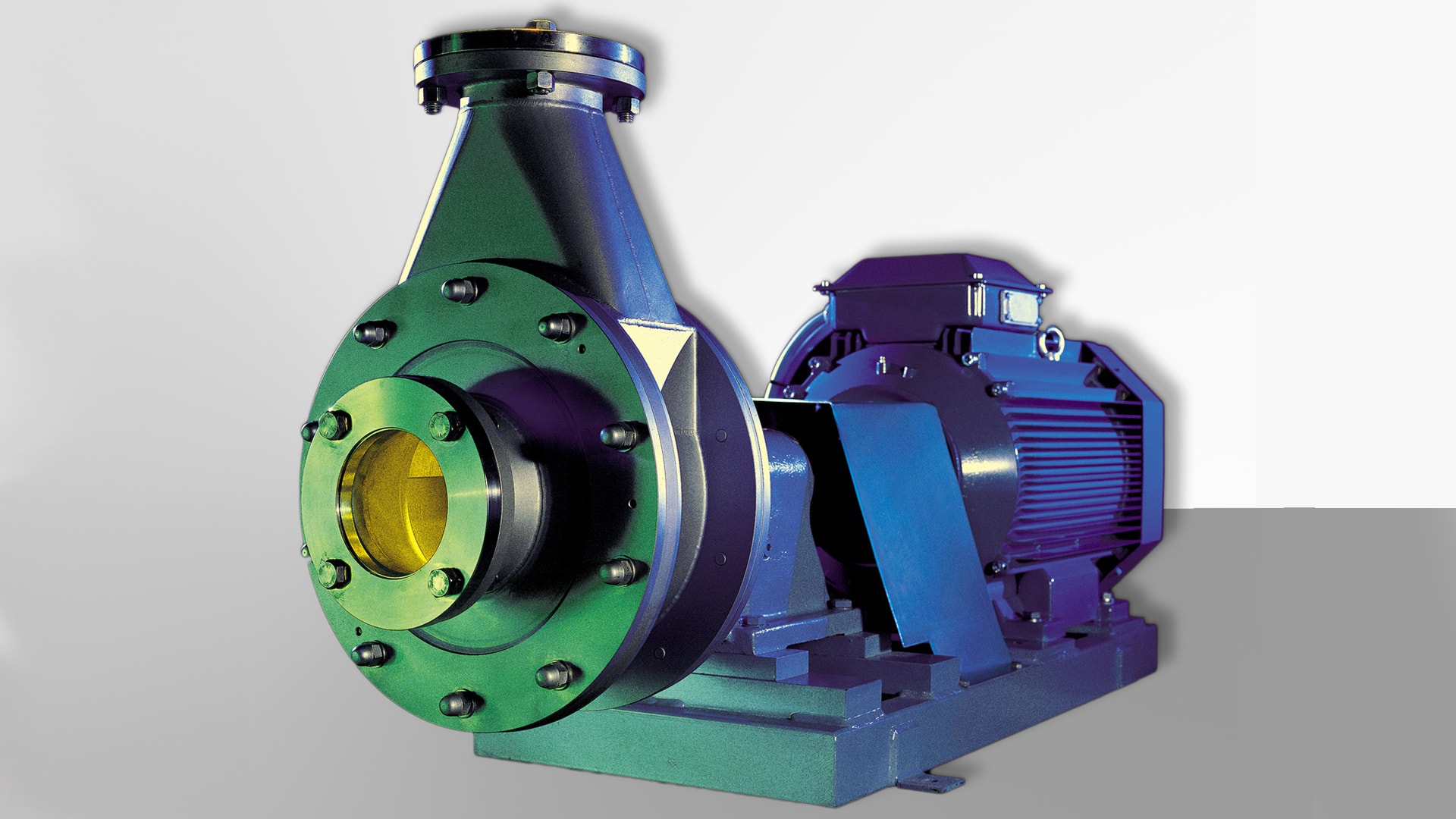

Pump PTR30

-

Industries:

- Fruit

- Tomato

- Vegetables

-

Max Capacity:

- Up to 1,500 tons/day

Benefits

Achieves uniform breakage of fruits for subsequent heating and refining.

Optimizing heating and refining process thanks to the uniformity of the chopped products being heated.

Suitable for processing tomatoes, stoneless fruits, and vegetables.

A very reliable service factor guarantees prolonged working cycles.

Features

Features

- Robust 30 kW motor for efficient and powerful operation

- Capacity of 60 tons per hour

- It can be placed in both Cold-Break and Hot-Break systems

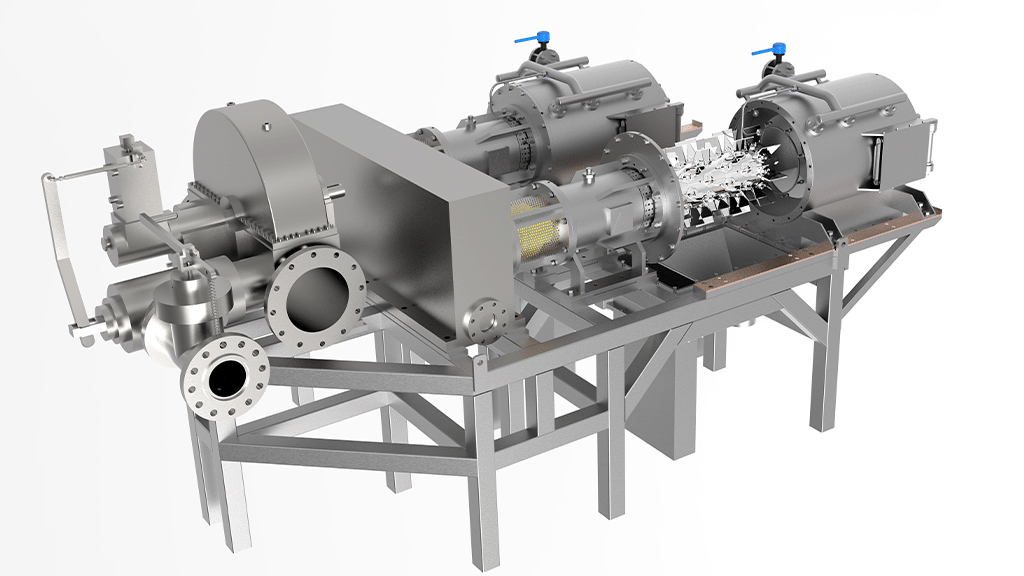

Giubileo

-

Industries:

- Fruit

- Tomato

- Vegetables

-

Min. Capacity:

- 48 tons/day

-

Max Capacity:

- 3,000 tons/day

Benefits

100% food compliant and eco-friendly thanks to the rubber-free destoning system which ensures product purity.

Achieving high yields with minimal waste (96% of finished product from apples with just 4% waste).

Prevents oxidation and preserves pure taste and color by removing peels, seeds and stems.

The innovative paddle pitch inclination adjustment parameter allows fine-tuning of the machine

Features

Features

- Array

- Array

- Pomace Humidity Reduction

- Array

- Available also in a compact version

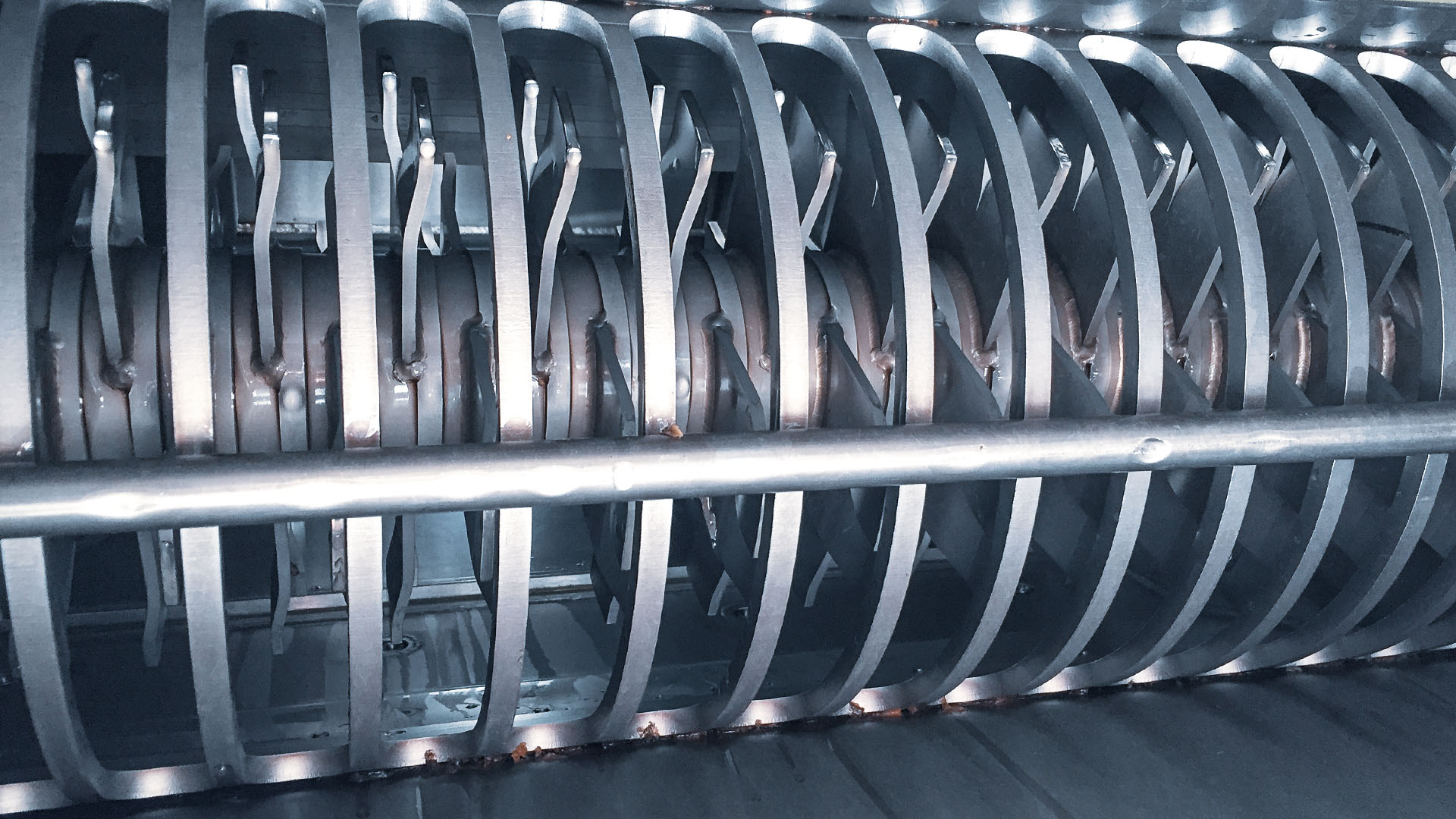

Crushing Mill

-

Industries:

- Fruit

- Tomato

- Vegetables

-

Max Capacity:

- Up to 1,000 tons/day

Benefits

High processing efficiency, enabling rapid and effective extraction of juices or pulps.

Flexibility in handling a variety of fruits and vegetables without compromising performance.

Minimum heat generation and mechanical stress during the crushing process contribute to superior product quality.

Minimizes the risk of rubber contamination, ensuring the purity of the final product.

Features

Features

- Durable materials and robust construction contribute to longevity and reduce frequent replacements

- Easy maintenance and cleaning

- Capacity up to 1,000 ton/day

No machine found. Please use fewer filters.