Fruit processing lines

Machines and complete lines for fruit processing designed to preserve the organoleptic features of fresh fruits.

Our technologies for fruit processing help you to achieve unrivaled quality while obtaining the highest possible yield.

Our patented systems for extraction and enzymatic deactivation guarantee optimal production results.

Benefits

Extensive flexibility

Adjustable paddles pitch to adapt to most types of fruits and vegetables.

Rapid inactivation of enzymes

Few seconds from whole fruits to extracted and deactivated puree.

Excellent color

Optimal preservation of color of processed fruits (up to 25% better Hunterlab “L” value compared to peers).

Easy maintenance

Quick paddles replacement, easy and safe rotor extraction. Rotor with reversible direction of rotation to balance wear on paddles.

Rubber-free destoning system

Thanks to the new rubber-free destoning system, there is no traditional rubber roll, granting 100% food compliace and eco-friendly processing.

Receiving, Washing & Brushing

Receiving, Washing & Brushing

Sorting

Sorting

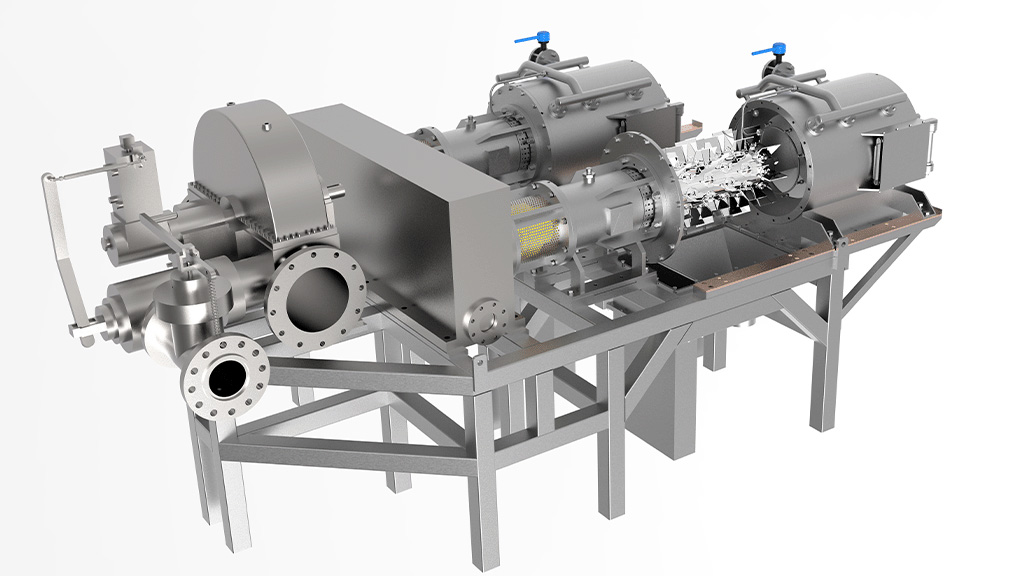

Extraction and Enzymatic inactivation system

Extraction and Enzymatic inactivation system

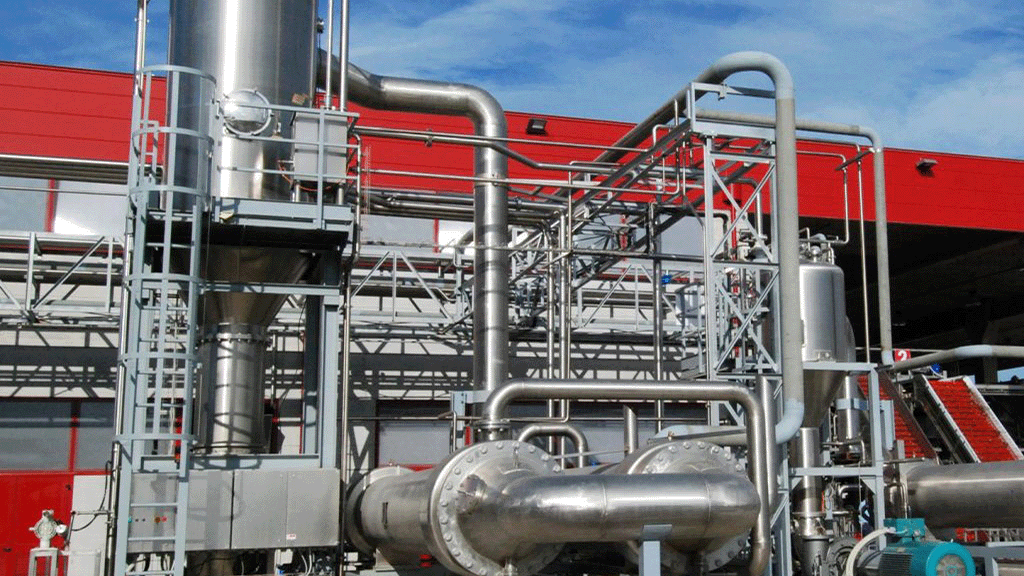

Concentration

Concentration

Sterilization

Sterilization

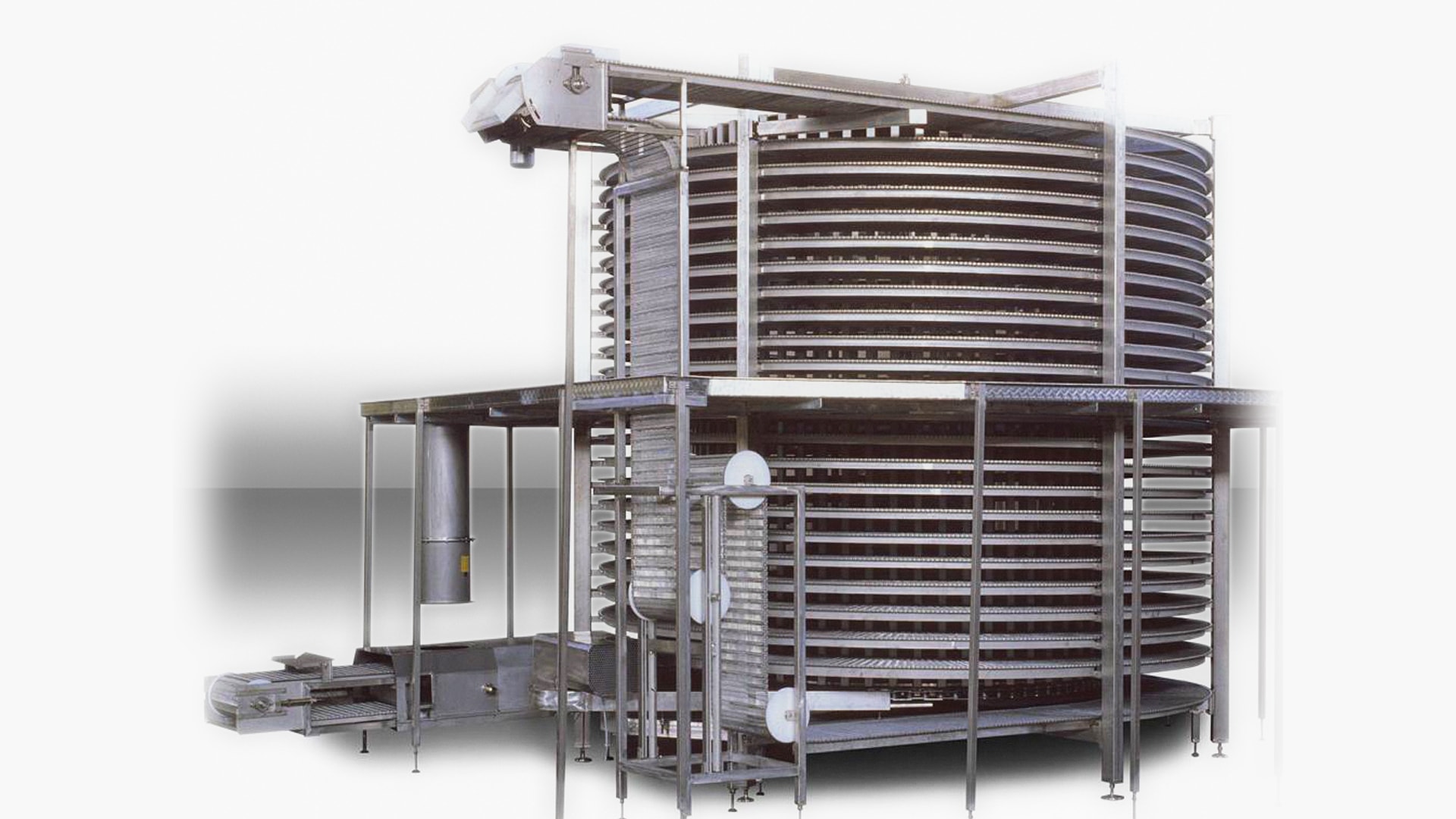

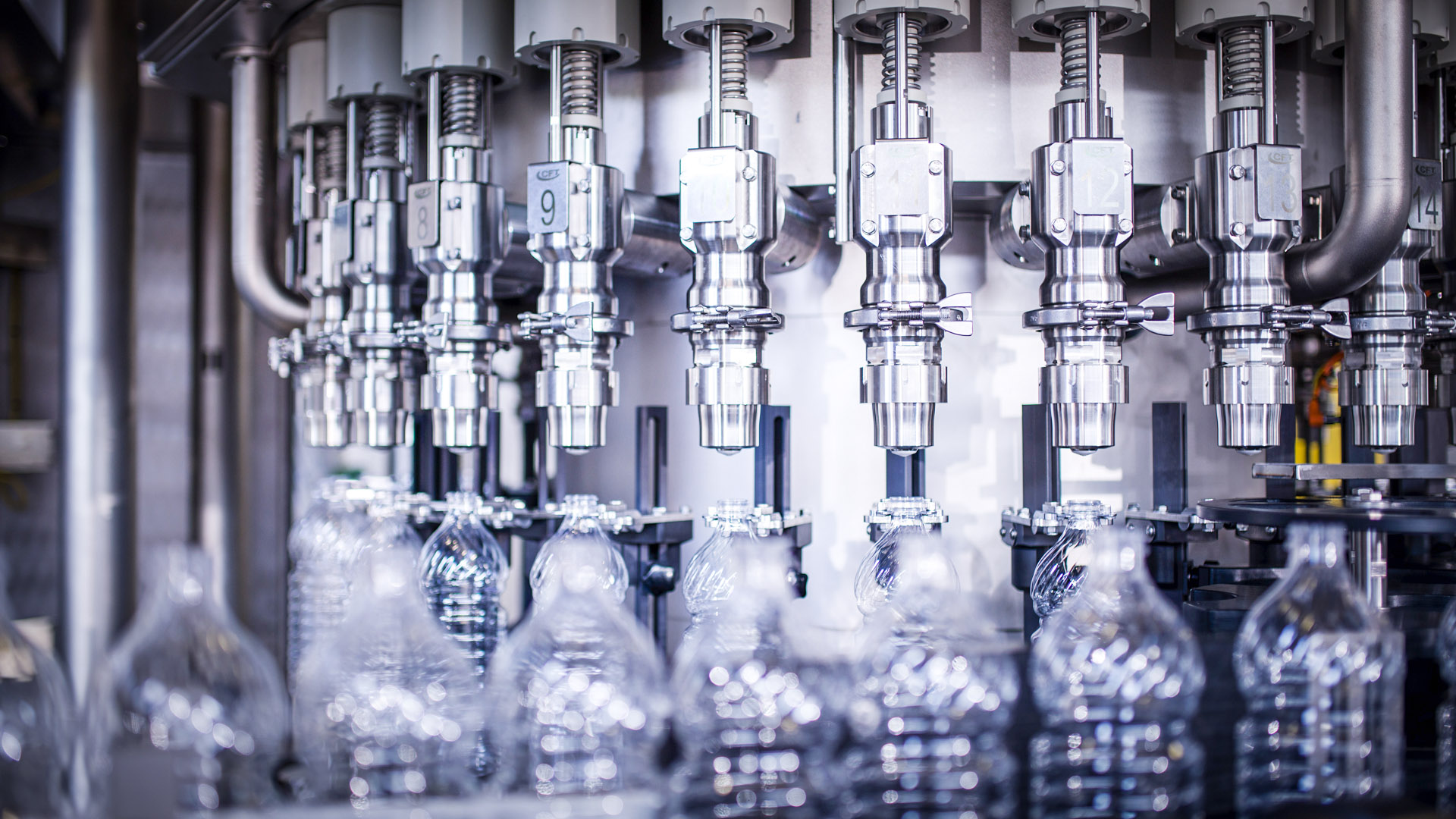

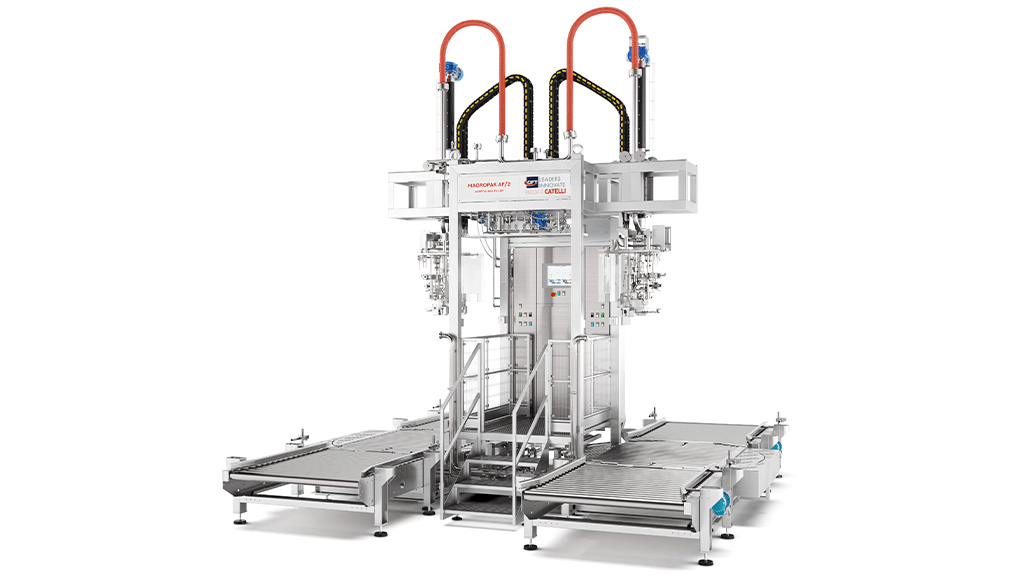

Aseptic filling

Aseptic filling

CIP unit & Tanks

CIP unit & Tanks

Receiving, Washing & Brushing

Receiving, Washing & Brushing

Fruit skin treatment

Fruit skin treatment

Sorting & Cutting

Sorting & Cutting

Extraction & Refining

Extraction & Refining

Enzymatic inactivation

Enzymatic inactivation