Fillers

Our filling equipment is designed for food and beverage products, with performance up to 70,000 cph.

The quality of each filling machine can be tested in advance in our laboratory. Our performance monitoring softwares are essential for optimizing production.

Weightech E

-

Industries:

- Edible Oil

- Ketchup, Sauces, Jams

-

Min. Capacity:

- 3,000 containers/hour

-

Max Capacity:

- 45,000 containers/hour

-

Container:

- Bottles (Glass)

- Bottles (PET)

- Cans

-

Technology:

- Load Cell

Benefits

The same valve can fill formulated products like ketchup and mayonese, and edible oil.

Sauces, creams and edible oil are filled uniformly and with no product waste.

The load cell technology can feature different alghoritms to guarantee the best possible precision.

Features

Features

- Pressurization system for high viscosity products

- Tare function

- Certification of the weight of the product

- Filling valves controlled by PLC

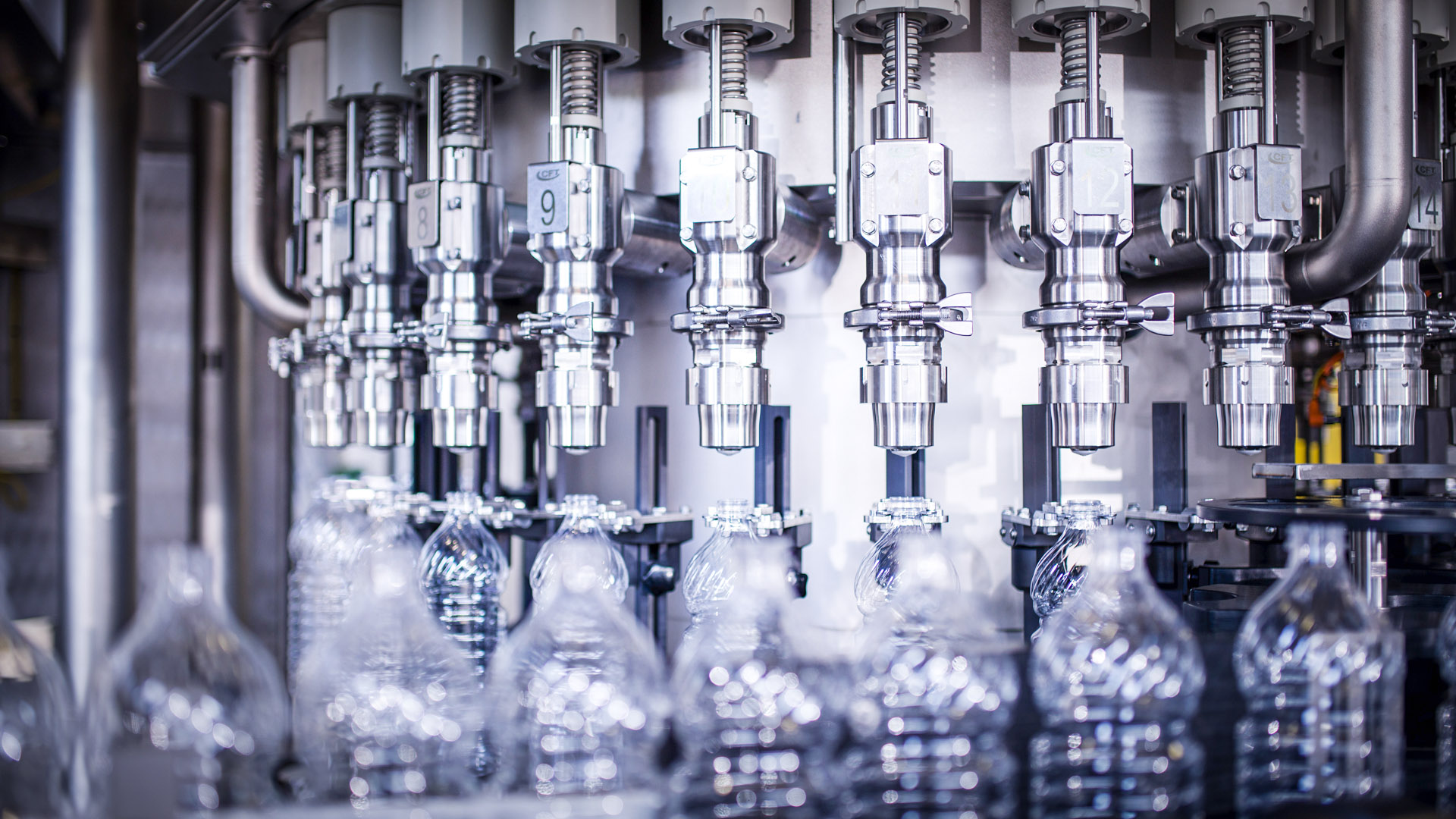

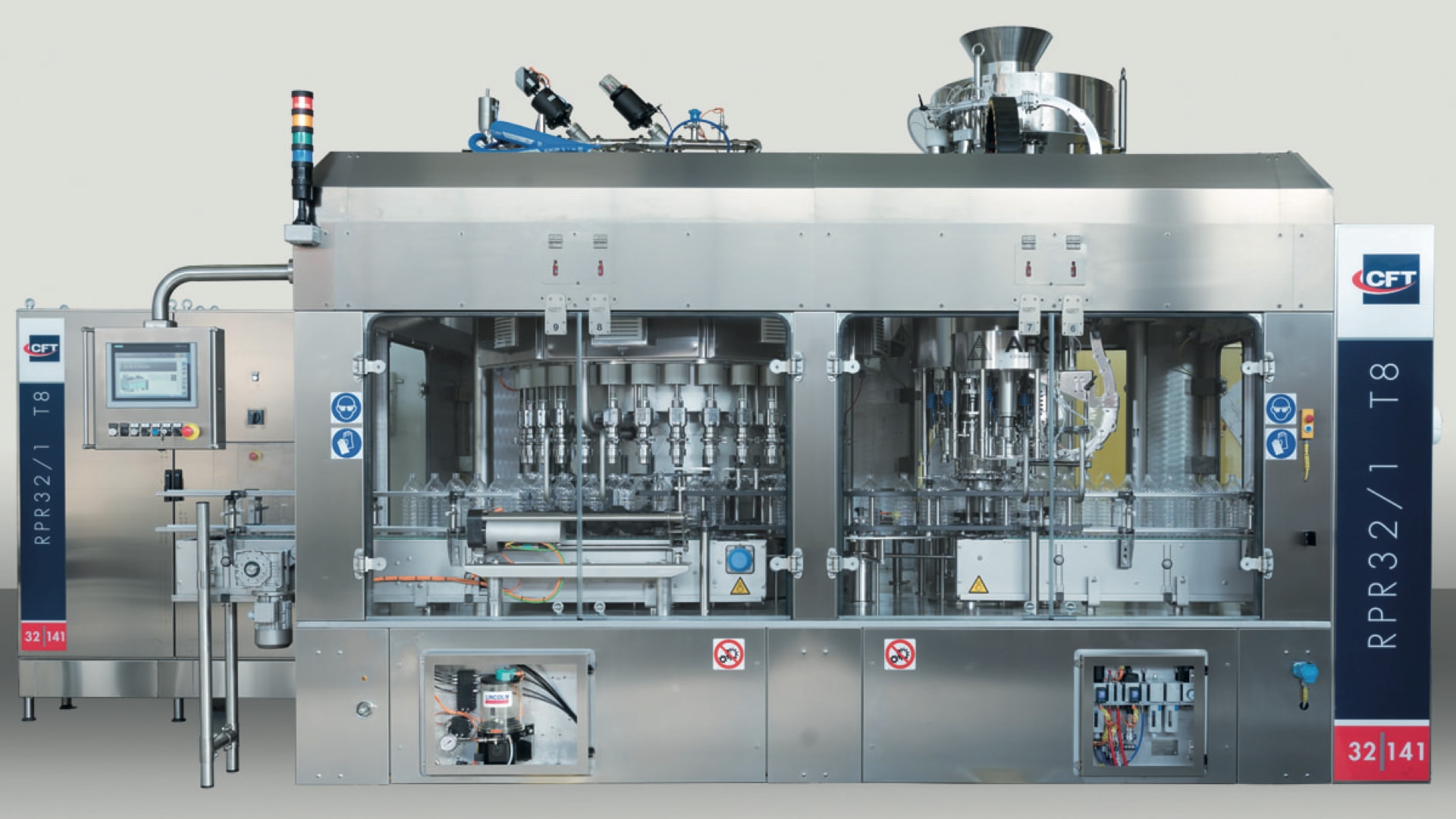

Master RS

-

Industries:

- Beverage

-

Min. Capacity:

- 3,000 containers/hour

-

Max Capacity:

- 70,000 containers/hour

-

Container:

- Bottles (Aluminum)

- Bottles (Glass)

- Bottles (PET)

-

Technology:

- Level

Benefits

The filling valves are constantly monitored by the PLC.

The special design makes it easy to maintain high standards of cleaning for all the components.

The valve is designed to gently treat the product, without altering its natural characteristics.

The machine can fill carbonated soft drinks, still drinks and beer.

Features

Features

- Multiple block configuration available

- Centralized decompression recovery system

- From 12v to 132v

- Filling valves controlled by PLC

Master C Tech

-

Industries:

- Beverage

-

Min. Capacity:

- 3,000 containers/hour

-

Max Capacity:

- 70,000 containers/hour

-

Container:

- Cans

-

Technology:

- Flow Meter

Benefits

The flow-meter technology guarantees a high precision in filling.

The Master C Tech is coupled with an electronic seamer for a perfect closure of cans.

Filling valves, chucks and rolls are designed and manufactured to guarantee the best performances.

Features

Features

- Up to 132 filling valves and 4 seaming heads

- Filling valves controlled by PLC

- Optional automatic dummy caps

Master C Block

-

Industries:

- Beverage

-

Min. Capacity:

- 3,000 containers/hour

-

Max Capacity:

- 15,000 containers/hour

-

Container:

- Cans

-

Technology:

- Flow Meter

Benefits

A very low percentage of oxygen pick up is guaranteed.

Downsized footprint with very high production standard: suitable for limited space and easy to install.

The flow-meter technology guarantees a high precision in filling.

Filling valves, chucks and rolls are designed and manufactured to guarantee the best performances.

Features

Features

- Up to 24 filling valves

- Filling valves controlled by PLC

- Optional automatic dummy caps

Magnum VF

-

Industries:

- Fruit

- Other Foods

- Tomato

- Vegetables

-

Min. Capacity:

- 3,000 containers/hour

-

Max Capacity:

- 70,000 containers/hour

-

Container:

- Cans

- Jars (Glass)

-

Technology:

- Volumetric

Benefits

The air inside the container is completely eliminated before filling.

The residual air above the product is removed with a steam jet before closing the containers.

This volumetric filling system is very reliable and needs a minimun maintenance effort.

Features

Features

- Height adjustment for size change with handwheel

- Complete with filter, steam valve, and condensation discharge

- Optional heating coil in stainless steel to maintain the liquid temperature inside the hopper

Magnum Clean PF

-

Industries:

- Ketchup, Sauces, Jams

- Milk & Dairy

- Tomato

-

Min. Capacity:

- 3,000 containers/hour

-

Max Capacity:

- 70,000 containers/hour

-

Container:

- Bottles (Glass)

- Cans

- Jars (Glass)

-

Technology:

- Volumetric

Benefits

The mechanical nature of this machine makes it very resistant and high-performance.

Suitable for liquid, viscous or dense food products.

The Master RS can be coupled with seamers or cappers depending on the production necessities.

Features

Features

- Range from 6 to 72 valves with 500 to 5,000 cc cylinders

- Centralized lubrication system

- Openable panels and electromechanical device for safety stoppage

Magic FW

-

Industries:

- Beverage

- Ketchup, Sauces, Jams

- Milk & Dairy

-

Min. Capacity:

- 5,000 containers/hour

-

Max Capacity:

- 70,000 containers/hour

-

Container:

- Bottles (Glass)

- Bottles (PET)

- Jars (Glass)

-

Technology:

- Flow Meter

Benefits

Constant filling accuracy whether dosing small or large volumes.

The machine can be synchronized with a seamer or a capper depending on the containers used.

The machine is designed to meet the highest requirements of hygiene, especially for beverage filling.

Features

Features

- Filling valves controlled by PLC

- Optional configuration for hot filling

- Optional dummy cans

- Quick size change-over and centralized lubrication system

No machine found. Please use fewer filters.