As CFT Group, we can supply turn-key beer production systems starting from the raw material intake up to the finished beer for brew sizes from 10 HL up to 500 HL, as well as the appropriate filling and packaging solutions for beer in bottles, cans and kegs.

Beverage preparation & packaging

Efficiency in every drop:

our complete Beverage solutions.

Custom-made syrup rooms and highly precise fillers are part of our everyday business. We support small companies and international groups to design and install beverage preparation and beverage packaging solutions.

Benefits

Turn-key lines

Complete turn-key lines for beverage preparation and packaging, completely customized.

Integrated control system

Our HMI platforms Memento, Illuminate and FACTS can monitor machines and lines performance in a simple and intuitive way.

Hygienic design

Compliance with European and international guidelines.

Easy maintenance

Easy and cost-effective maintenance thanks to long-life wear components.

Unmatched quality

Technologies that guarantee an excellent product quality.

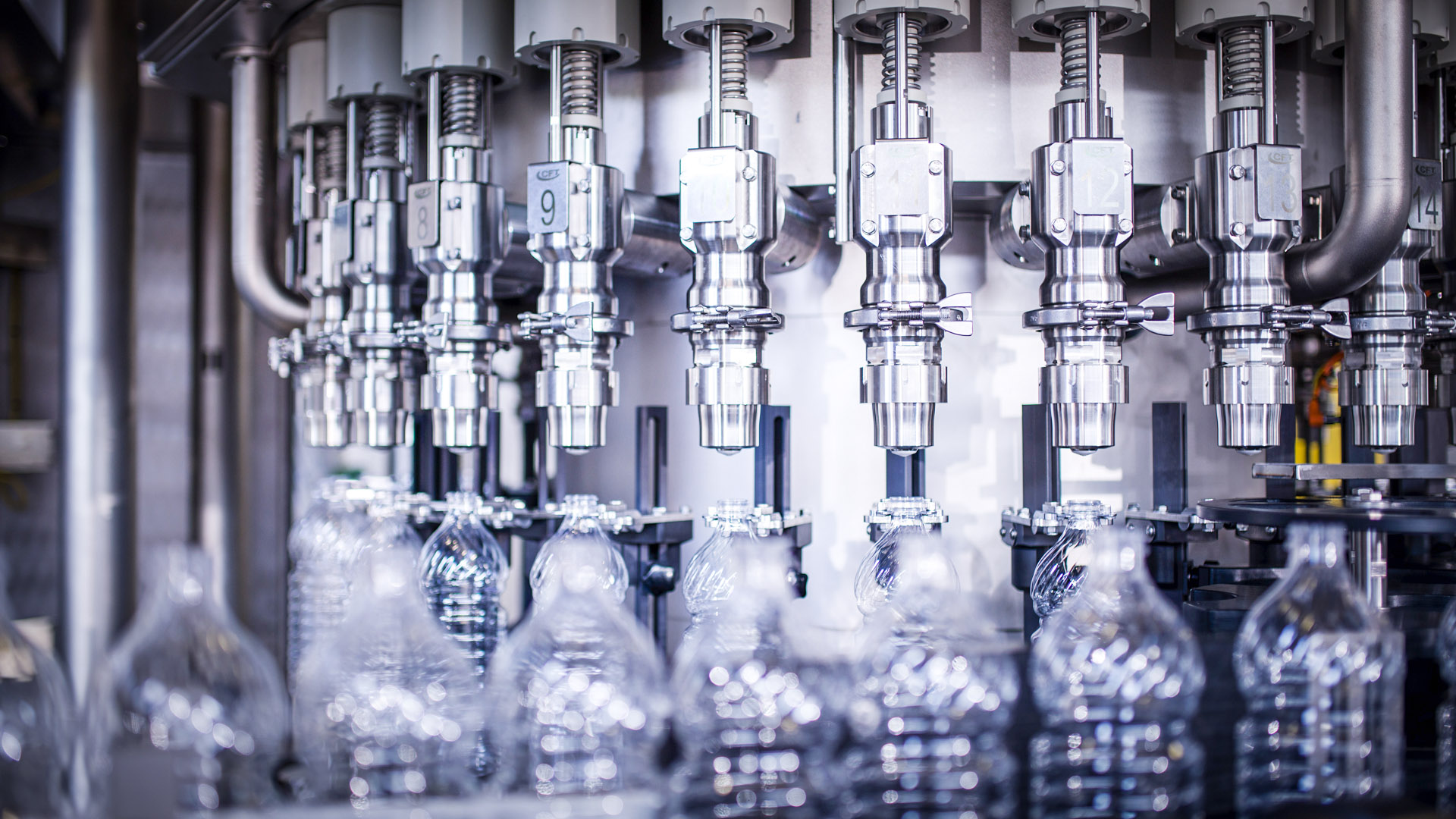

Filling precision

The swirl unit inside the filling valve is capable of operating perfect deflections on almost all containers on the market.

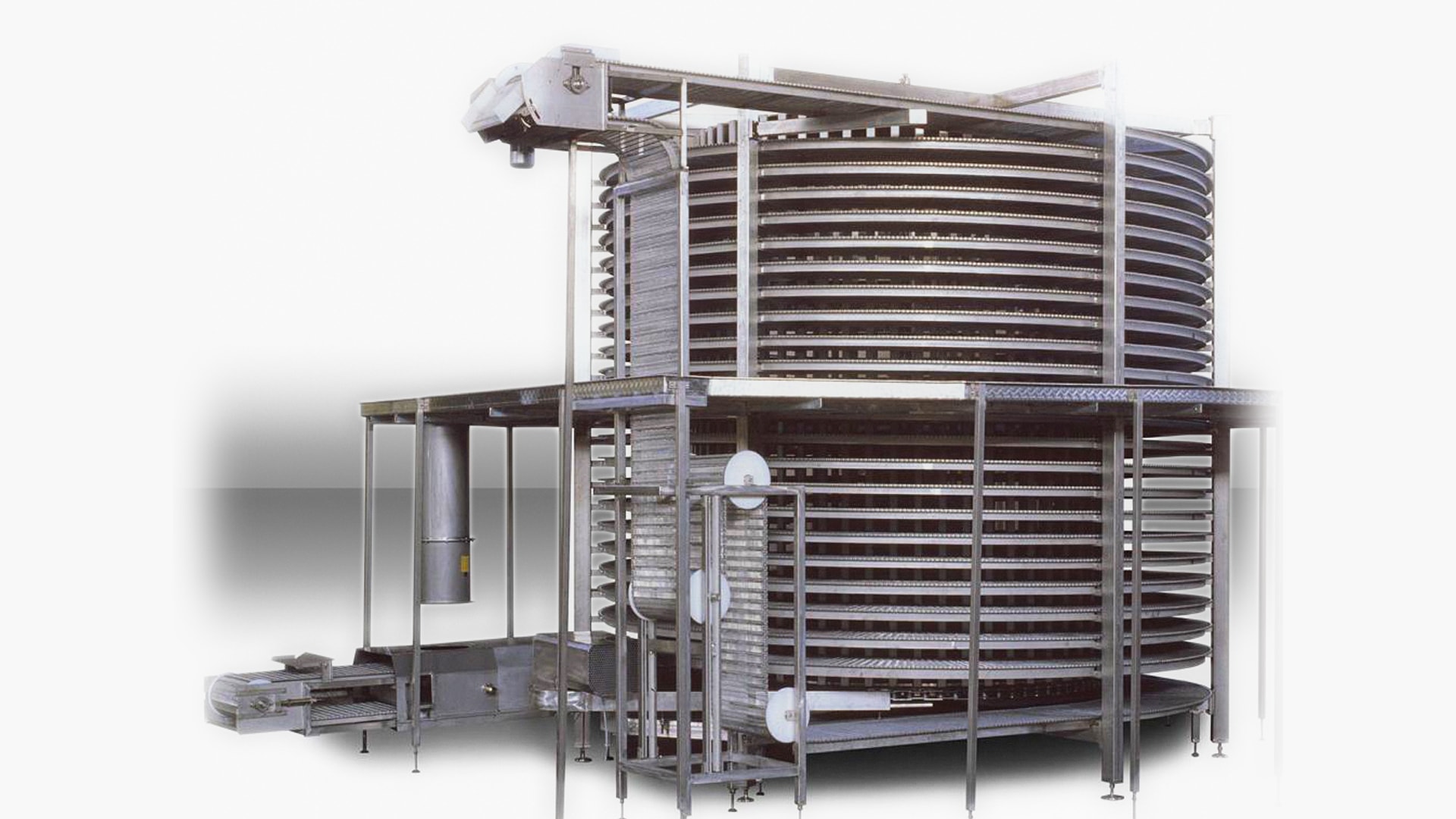

Ingredients storage & Preparation

Ingredients storage & Preparation

Water storage

Water storage

Blending

Blending

Deaeration and carbonation

Deaeration and carbonation

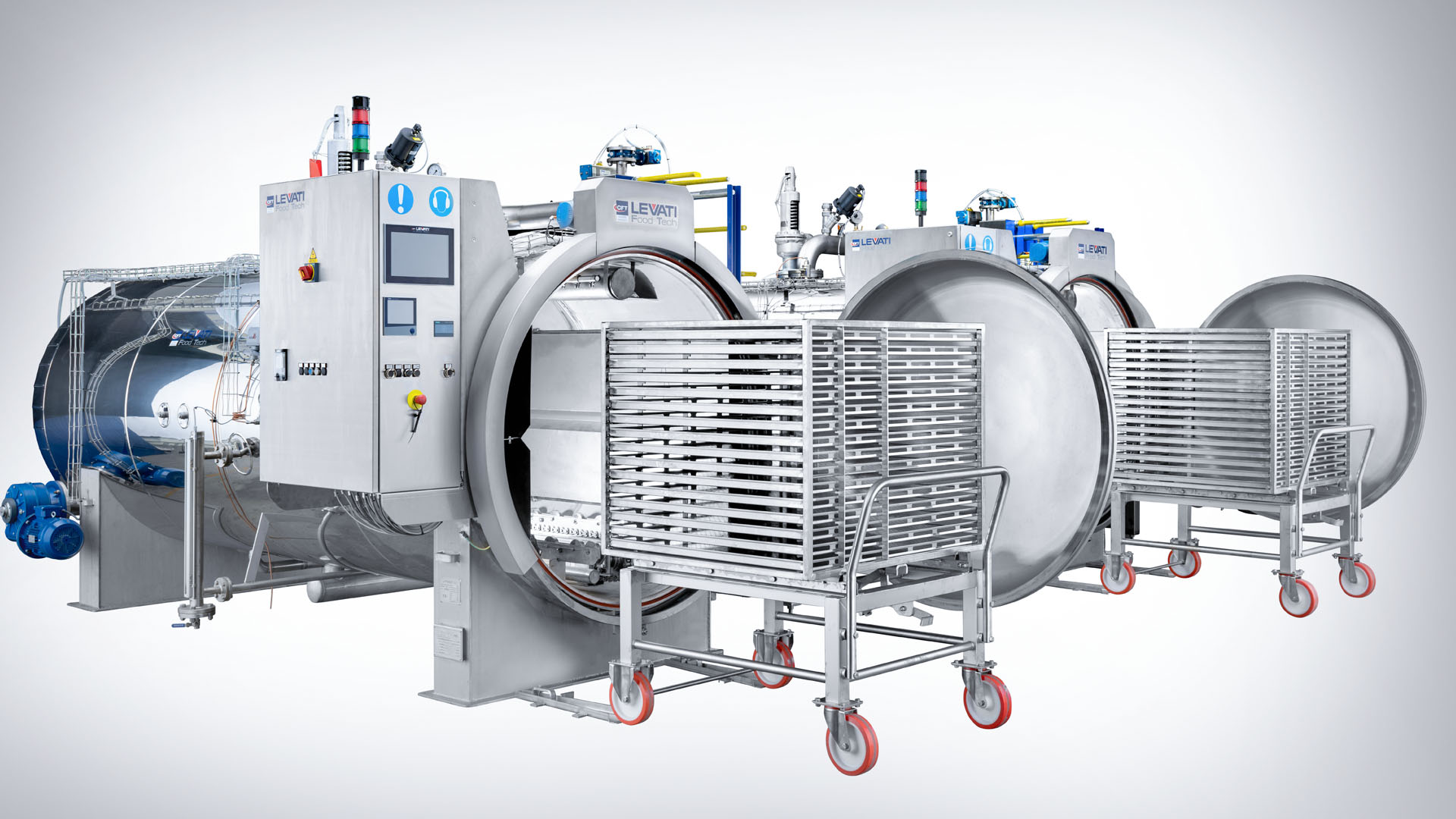

Pasteurization

Pasteurization

CIP Unit

CIP Unit