Mixers and Cookers

Processing systems for the production of fruit-based products, baby food and formulated products.

Mixing and cooking systems allowing us to offer a great production flexibility. These machines grant to process liquid and homogenized food as well as chunky foods and liquid food with particles.

Vulcano Cooker/Mixer

-

Industries:

- Fruit

- Ketchup, Sauces, Jams

- Tomato

-

Min. Capacity:

- 1,000 liters

-

Max Capacity:

- 3,400 Liters

Benefits

The unit is tailor made on the production necessities, providing an uncomparable quality of the final product.

A wide range of different operations can be performed with an outstanding level of quality.

The technology behind the Vulcano cooker is proprietary, resulting in an unmatched quality level.

Features

Features

- Simplicity meets versatility. One vessel for mixing, frying, cooking, and more, streamlining production

- Cooker’s unique heating ratio ensures swift cooking, reducing process time for heightened productivity

- Impeccable interior, innovative scrapers for easy cleaning, reducing time, maintaining hygiene standards

- Available sizes: 1000 – 1500 – 2000 – 3400 liters

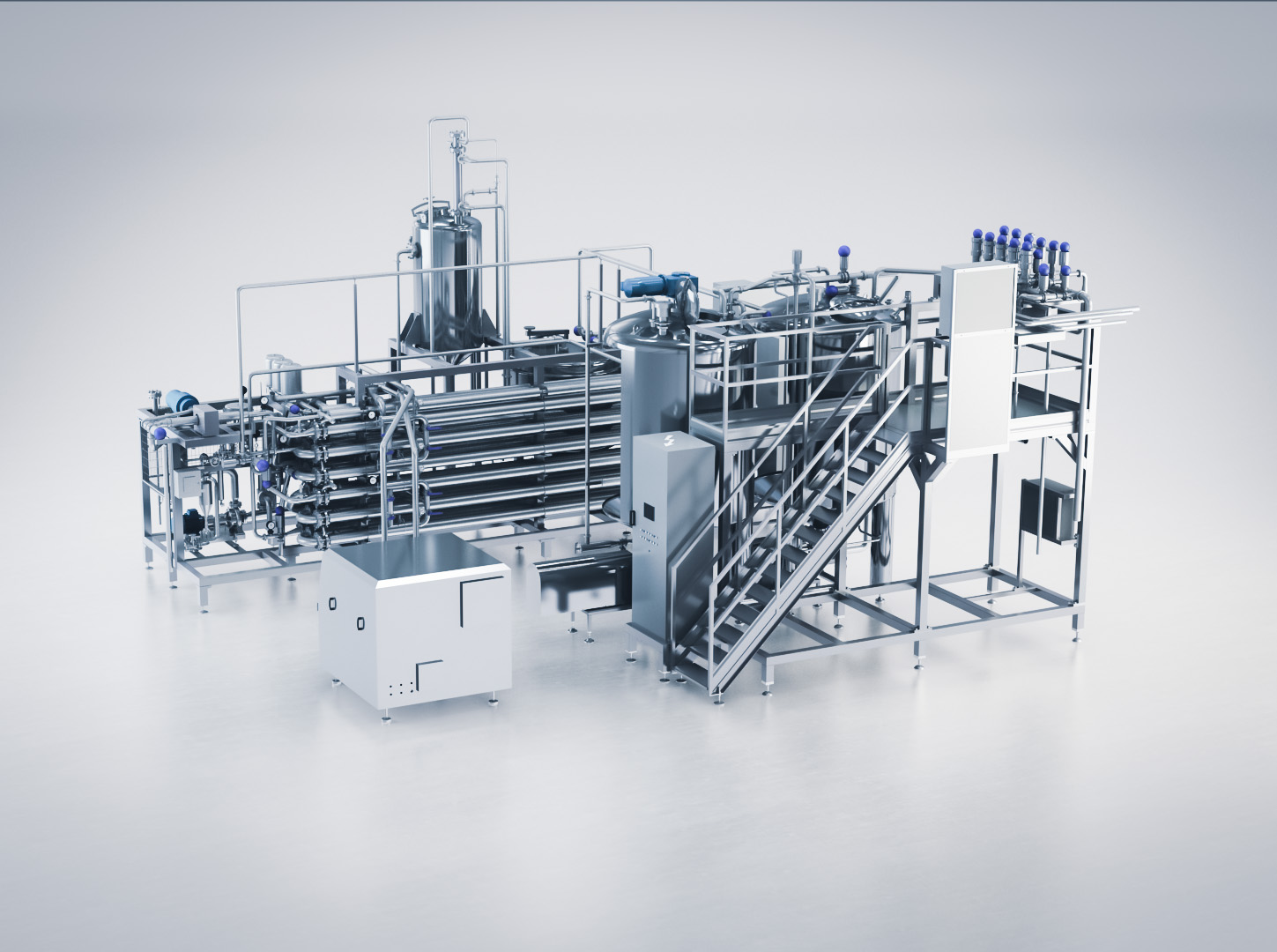

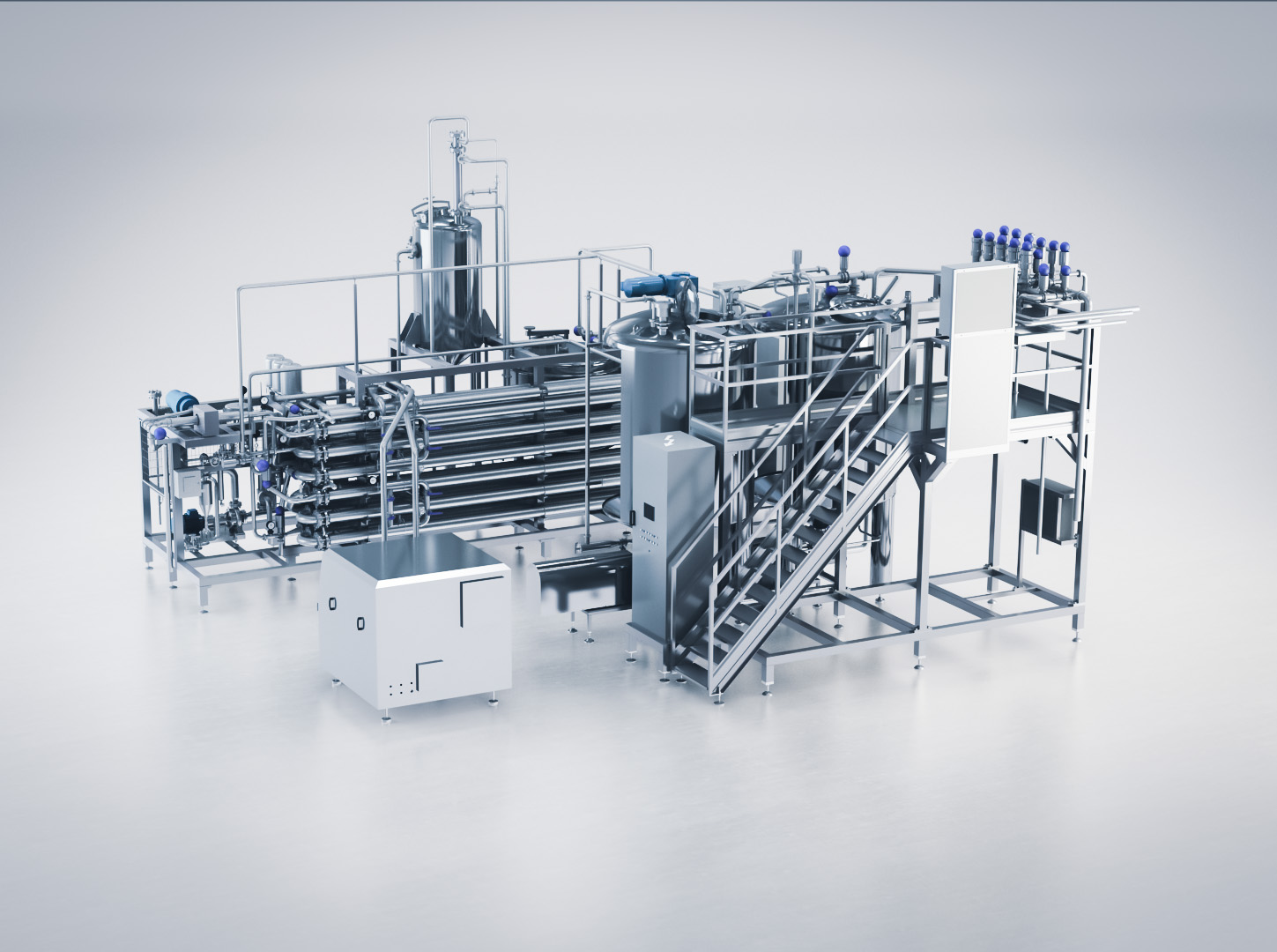

Titano Rotary Coil

-

Industries:

- Fruit

- Ketchup, Sauces, Jams

- Vegetables

-

Min. Capacity:

- 600 Liters

-

Max Capacity:

- 3,200 Liters

Benefits

Effective mixing and uniform heating temperature of the product with minimal damage to the integrity of particulates.

The internal rotary coil heat exchanger offers high flexibility for diverse recipe requirements.

Precise temperature control for consistent quality in fruit-based, bakery toppings, and sauces production.

Features

Features

- Excellent heat transfer coefficient thanks to the rotary coil heat exchanger

- Excellent cleaning and sanitation

- Available sizes: 600 – 1200 – 2400 – 3200 liters

Saturno Mixing Tank

-

Industries:

- Fruit

- Ketchup, Sauces, Jams

- Tomato

-

Min. Capacity:

- 500 liters

-

Max Capacity:

- 10,000 Liters

Benefits

Maintenance of product integrity and qualities containing diced fruit.

Saturno technology ensures homogeneous blending for consistent product quality.

Efficient storage/buffer system preserves freshness and minimizes product waste.

Features

Features

- Homogeneous and fast mixing

- Uniform temperature distribution

- Agitator speed modulation driven by frequency converter

Jupiter

-

Industries:

- Ketchup, Sauces, Jams

Benefits

CFT Jupiter ensures rapid and uniform blending, optimizing ketchup ingredients for consistent flavor.

High-speed stirring accelerates preparation, decreasing production cycles and enhancing overall efficiency.

Precision in mixing improves texture and taste, ensuring a superior and homogeneous ketchup product.

Features

Features

- Efficient agitator for thorough mixing

- Frame with adjustable brackets

- AISI 304 stainless steel parts for product contact

No machine found. Please use fewer filters.