Pasteurization, Cooling and Freezing Line for Mushrooms

Food requires respect, precision and culture, because “we are what we eat”. This is the philosophy with which Paolo Scapin founded Nova Funghi in 1980, creating a vast range of delicacies and a plethora of dedicated production lines, such as mushrooms, artichokes, olives, asparagus, grilled vegetables and vegetable creams.

Our collaboration with Nova Funghi, which began a few years ago, has recently resulted in a new project: a pasteurization, chilling and freezing line for mushrooms in thermoformed trays.

Among the founding values of the Veneto-based company are quality and the importance of safety in the food that it produces. At CFT, we have been committed to providing innovative solutions for food processing and preservation for over 75 years, aware of the importance of ensuring both a product’s microbiological safety and the preservation of its sensory and nutritional qualities. We are therefore proud to be able to actively support our customers in the practical application of these shared principles.

The pasteurization, cooling and freezing line for mushrooms in trays

Nova Funghi’s requirement was to be able to handle different heat treatments for mushrooms in trays of varying formats in an extremely quick and flexible manner.

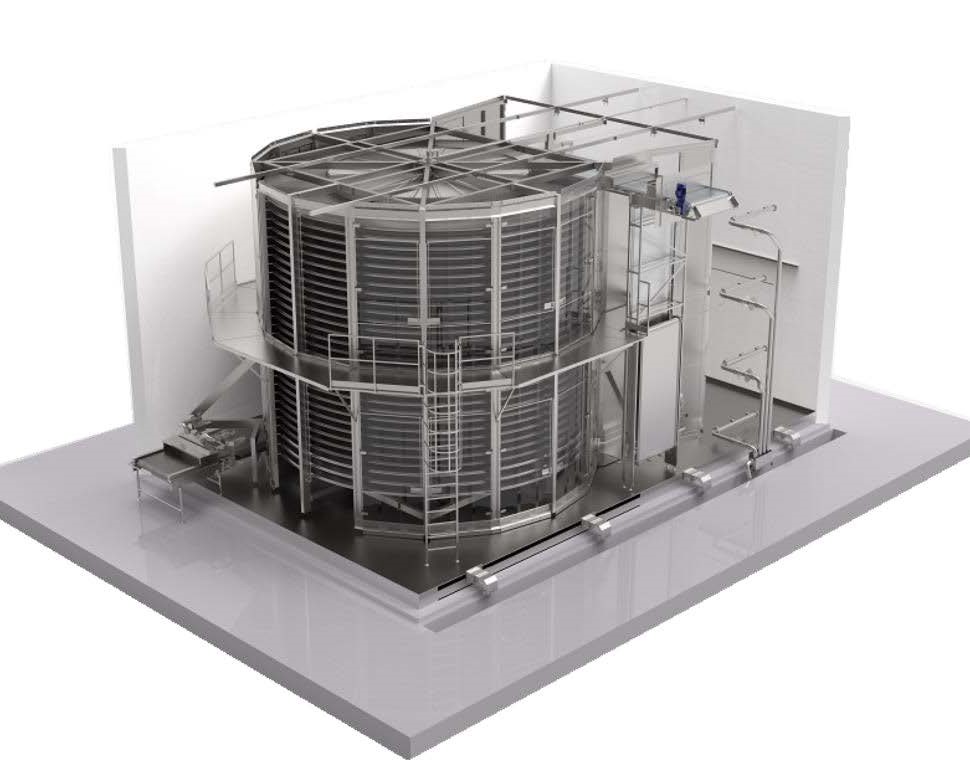

To meet this need, we supplied a line consisting of three different spiral machines:

1) MECspray – water pasteurizer with ascending spiral

2) MECspray – water coooler with descending spiral

3) SPIRAfreeze – air freezer with ascending spiral

CFT MECspray

CFT Spirafreeze

A single line for different product heat treatment cycles

The mushrooms in the tray, arriving from the filling machine, reach a divider that diverts the packages in order to exploit the width of the machine belt to the maximum.

At this point, our three spiral machines enable the customer to carry out three different heat treatment cycles depending on the desired end product, be it a chilled or frozen product:

Cycle 1: Pasteurization and chilling

With this type of treatment, the first MECspray water spiral acts as a pasteurizer, heating the product to approximately 93/95°C; the second MECspray spiral cools the trays to a temperature of 36°C, thus preparing them for the third stage. During this final stage, the SPIRAfreeze air spiral further cools the product down to 4°C.

Cycle 2: Pasteurization and freezing

In this case, the MECspray water pasteurizer performs the same function as the treatment described above, i.e. it heats the already packaged product up to approximately 93/95°C. What varies in this cycle are the temperatures of the second and third coils: the second MECspray water coil cools the trays down to a temperature of 12°C, while the third coil, the SPIRAfreeze air coil, freezes the product down to -18°C.

Cycle 3: Cooling and freezing

The third type of cycle makes it possible to use the first MECspray spiral as a cooler through the installation of an additional heat exchanger. The product at 60°C, in a closed container, coming from packaging is then cooled down to a temperature of 34°C. The second MECspray spiral allows further cooling of the pre-formed trays, down to 8°C. Lastly, the SPIRAfreeze air freezer brings the final product down to a temperature of -18°C.

Advantages of CFT spiral systems

1. Heat treatment flexibility: one line for three different cycles

The solution we proposed to Nova Funghi provides exceptional flexibility, allowing the first MECspray spiral to be used both as a pasteurizer and as a cooler, owing to two different exchangers (steam and water). In addition, all three spirals can be configured with different temperature settings to suit varying processing cycles.

All operations can be programmed directly from the control panel, allowing the type of cycle to be selected according to production requirements.

2. Adaptability in the handling of packages with different formats

The pasteurization, chilling and freezing line developed for Nova Funghi can easily be adapted to handle trays of different formats. The same machine can handle trays ranging from 200 grams up to 5 kg wholesale packs.

3. Specific advantages of continuous heat treatment

A continuous heat treatment system such as the spiral system has many advantages over a batch system:

- Energy efficiency: continuous heat treatment is much more energy efficient than a batch system where all cycles take place within the same machine.

- Production efficiency: continuous heat treatment enables continuous production, without interruptions or significant downtime.

- Increased food safety: continuous heat treatment allows the product to be processed instantly, guaranteeing greater food safety and uniformity of treatment across all production.

- Product quality: a continuous system can help maintain food quality over time. By using appropriate temperatures and processing times, it is possible to reduce nutrient degradation, preserve the appearance, flavour and texture of food and extend its shelf life.

- Cost reduction: the use of continuous heat treatment can lead to a reduction in production costs by minimizing waste and optimizing processes.

- Space optimization: spiral transport systems allow for the optimization of the available space, increasing the efficiency and handling capacity of products in a production environment.

Looking to the future

The global frozen food market size was estimated at $397.3 billion in 2022 and the frozen food market is expected to reach $607.2 billion by 2032, growing at an average annual rate of 4.4 per cent from 2023 to 2032. These estimates lay the foundation for fruitful future synergies.

Source: alliedmarketresearch.com