We first met Frutco’s management during the 2015 IFU conference. Their goal was to find a reliable partner to help them enter the South American market with a banana processing plant, a business of which CFT could already boast several references and a long-standing local presence.

Frutco is a company that has been active in the tropical fruit processing market for almost 30 years. From the very first meetings it became clear that their attention to the quality of the finished product was perfectly in line with the spirit of CFT Group. With these conditions in mind, we designed a banana processing plant for Frutco to be installed in Colombia, in the new plant of their sister company FruBaTec.

The complete banana processing line

The plant created is a turn-key line that includes all the equipment necessary for the reception, washing, peeling, sorting, heating, extraction, sterilization and aseptic filling phases.

Among the many machines that make up the line, at least three are worthy of special attention:

Giubileo extractor and refiner

Giubileo is CFT Group’s extraction / refining unit designed to ensure high performance, maximum flexibility, and state-of-the-art functionality. Thanks to its versatility, the machine is able to process a wide range of products, including, but not limited to, whole fruits, with or without stones and various types of vegetables, obtaining finished products that meet the highest quality standards.

Some of its main features are:

- Elimination of pre-peeling in the processing of fruit without stones by means of cold extraction, which allows a significant reduction in the amount of waste and in oxidation of the products.

- Constant yield: for Mediterranean fruits such as pears and apples, Giubileo can obtain 97% of the finished product with only 3% waste.

- Possibility of de-stoning products with stones using a “rubber free” system in which the fruits never come into contact with parts that are not in stainless steel.

- Integrity of the seeds, stones and stalks, to avoid the alteration of the taste during heating and the presence of foreign bodies in the final purée.

- Possibility of inclination of the rotor blades, which allows fine adjustments of the machine according to product specifications.

- Reduction in waste moisture.

Olimpic TC + SR sterilizer

High performance and maximum reliability characterize the Olimpic sterilization system, designed for processing products with high consistency and viscosity values, intended for subsequent aseptic filling.

Some of its main features are:

- Patented heat exchanger technology, with hygienic design, no stress due to thermal expansion, fully drainable.

- Quick and easy maintenance, without the need for complete extraction of the internal bundle.

- Capacity from 1,000 up to 18,000 kg / hour.

- Maximum heat exchange efficiency and process uniformity.

- Viscosity of the product up to 10,000 cp.

- Reduced washing times thanks to the counter-current included in the cycle.

For this particular project, the Olimpic TC sterilizer was equipped with 5 scraped surface heat exchangers, to raise the temperature of the product by means of boiler steam.

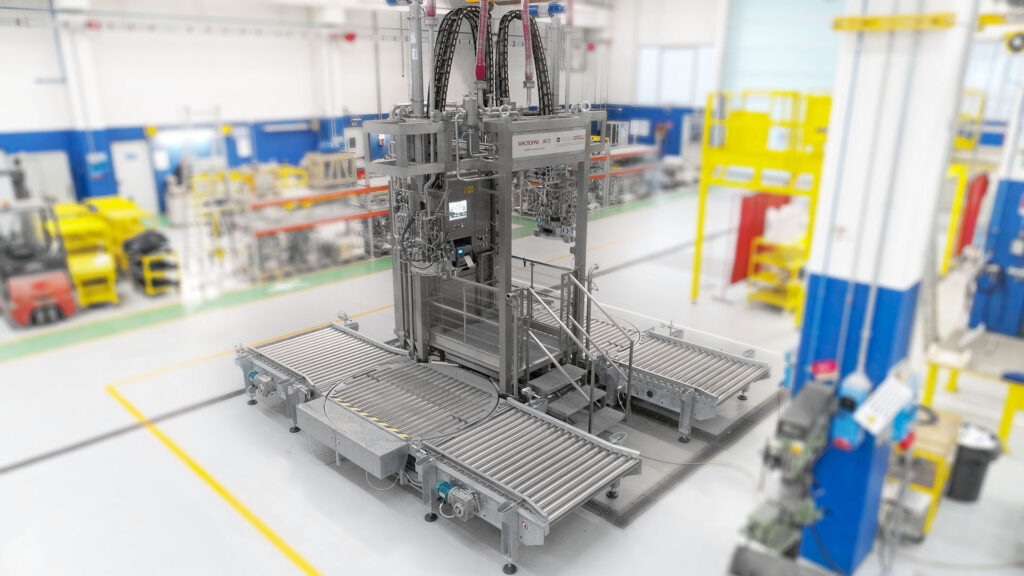

FDA certified Macropak aseptic filler

Macropak AF/2 is an innovative aseptic filler, capable of handling up to 3 different packaging formats.

Some of the key features of the machine are as follows:

- Designed for packing semi-finished or finished products, liquid or semi-liquid fluids, highly viscous products or products containing particulates.

- Products are aseptically filled into 200 litre or 1000 litre, pre-sterilized bags.

- Aseptic filling of 5 litre, 10 litre or 20 litre bags (pouches) is possible with the optional web fed kit, which can be easily mounted on the AF/2 when this format is necessary.

We requested and obtained the FDA certification for Macropak precisely with this project in mind, which has allowed the customer to obtain even more assurances regarding the quality and safety of the processing offered by CFT Group.

The most difficult challenge: the colour of the finished product

The final product obtained from this banana processing plant is an aseptic banana purée and pulp, which the customer then supplies to producers of fruit juices, baby food or other finished products.

Banana processing is a particularly challenging process from a quality point of view. For microbiological reasons, this fruit actually needs be treated at high temperatures, but at the same time it is necessary to maintain high standards for all the organoleptic properties.

Consequently, the characteristics of the finished product such as colour, taste and flavour must be as close as possible to the original ones, while at the same time guaranteeing a perfectly aseptic product.

Among these characteristics, colour is undoubtedly the most difficult to guarantee when dealing with this type of fruit: all the companies that process bananas actually know perfectly well that maintaining a natural colour is one of the key elements, and at the same time one of the most complicated of the whole process. One of our main challenges in this case was therefore obtaining an excellent result also from the point of view of colour.

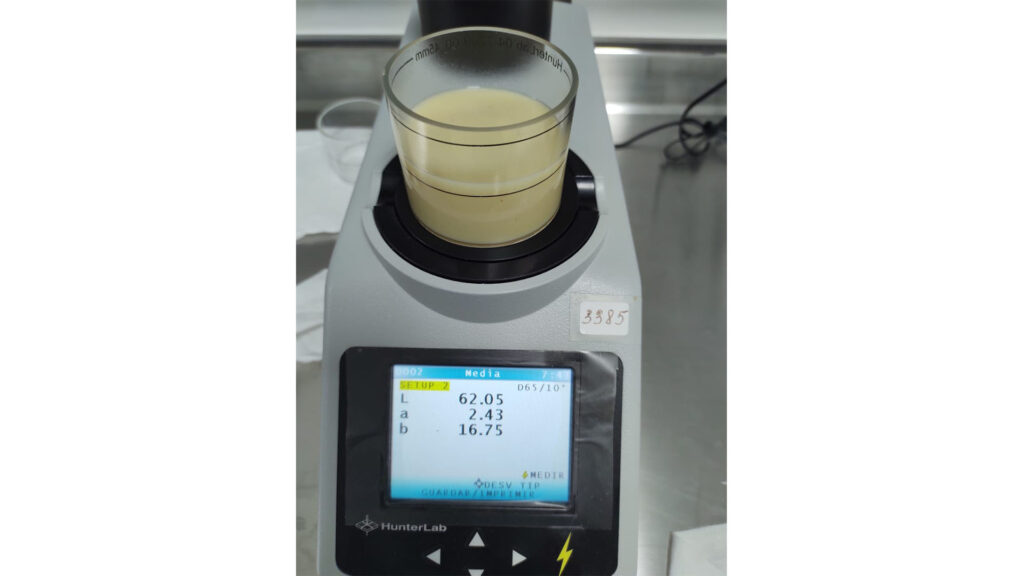

The reference system to which we refer for the measurement of colours is the HunterLab standard, composed of the three main values L (brightness), A (red gradient) and B (green gradient).

In general, each fruit, juice or purée is assigned ranges of values for each of the three HunterLab parameters, and the quality of the finished product is evaluated according to the range in which the measurement falls.

Although bananas have a tendency to easily turn pink with heat, thus moving away from their natural white / yellow colouring, the finished product made with our banana processing plant has been placed in the highest quality range for each of the three parameters L, A and B. Our customer was completely satisfied with this result, once again confirming the value of CFT Group design and technologies.

Next steps: lines for processing tropical fruits

Given the success of this project and the growing presence of CFT Group in the South American market, very favourable opportunities will be opening up in the coming years. The plant that is already installed will soon be expanded and dedicated to the processing of other tropical fruits such as passion fruit and mangoes, whose market is rapidly expanding.

In fact, according to a Reportlinker study, the global tropical fruit purée market will grow steadily over the next few years. In 2020, during the pandemic crisis due to COVID-19, it was estimated at $3.8 billion, and is expected to reach a size of $5 billion by 2027, with a CAGR of 4% over the 2020- 2027 period.

The CFT Team for this project:

- Mario Gozzi – Regional Sales Manager

- Fabio Tedeschi – R&D Processing Manager

- Lorenzo Annese – Technical Sales Engineer