Tomato processing and packaging

The leader in processing for tomato paste, sauce, puree, diced tomato pulp and peeled tomatoes. Since 1945.

Reduce CO2 emissions, save up to 90% of natural gas costs, and preserve the quality of your product with the best technologies for tomato processing.

Benefits

Energy efficiency and carbon footprint savings

Minimized environmental impact by reducing greenhouse gas emissions and reduced fuel costs with our electrically powered evaporation and concentrsation technologies.

Gentle treatment

Perfect preservation of product organoleptic characteristics through minimal thermal stress.

Versatile and large-capacity lines

With a single line it is possible to process up to 3,000 t/24h of raw material and obtain products with different viscosity values.

High performance

Long uninterrupted production cycles and minimal production waste (about 2%).

Processing monitoring

Abitlity to track the performance of production lines in real time, from individual machines to complex factories with plants in different parts of the world.

Unparalleled expertise

Our on-field experience is evidenced by more than 1,100 tomato processing and packaging plants installed over the past 30 years.

Hydraulic Transport System

Hydraulic Transport System

Washing & Sorting

Washing & Sorting

Chopping

Chopping

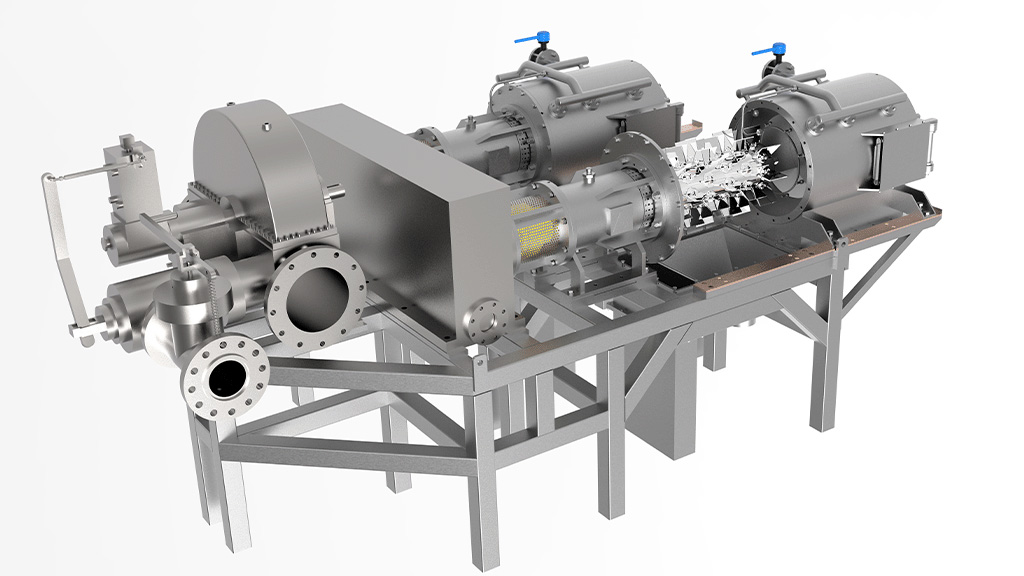

Enzyme Inactivation (Hot Break & Warm Break)

Enzyme Inactivation (Hot Break & Warm Break)

Enzyme Inactivation (Cold Break)

Enzyme Inactivation (Cold Break)

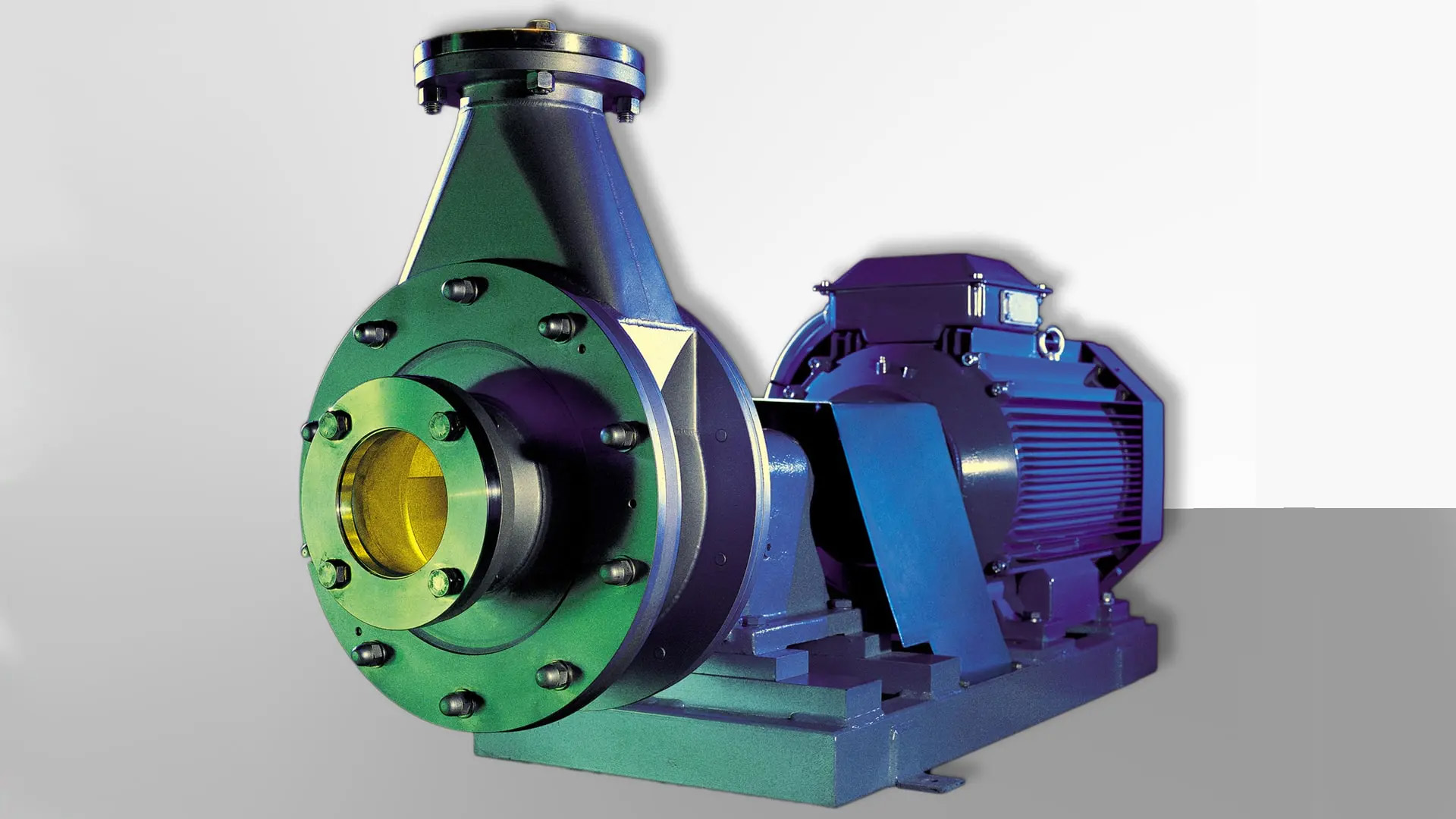

Juice Extraction

Juice Extraction

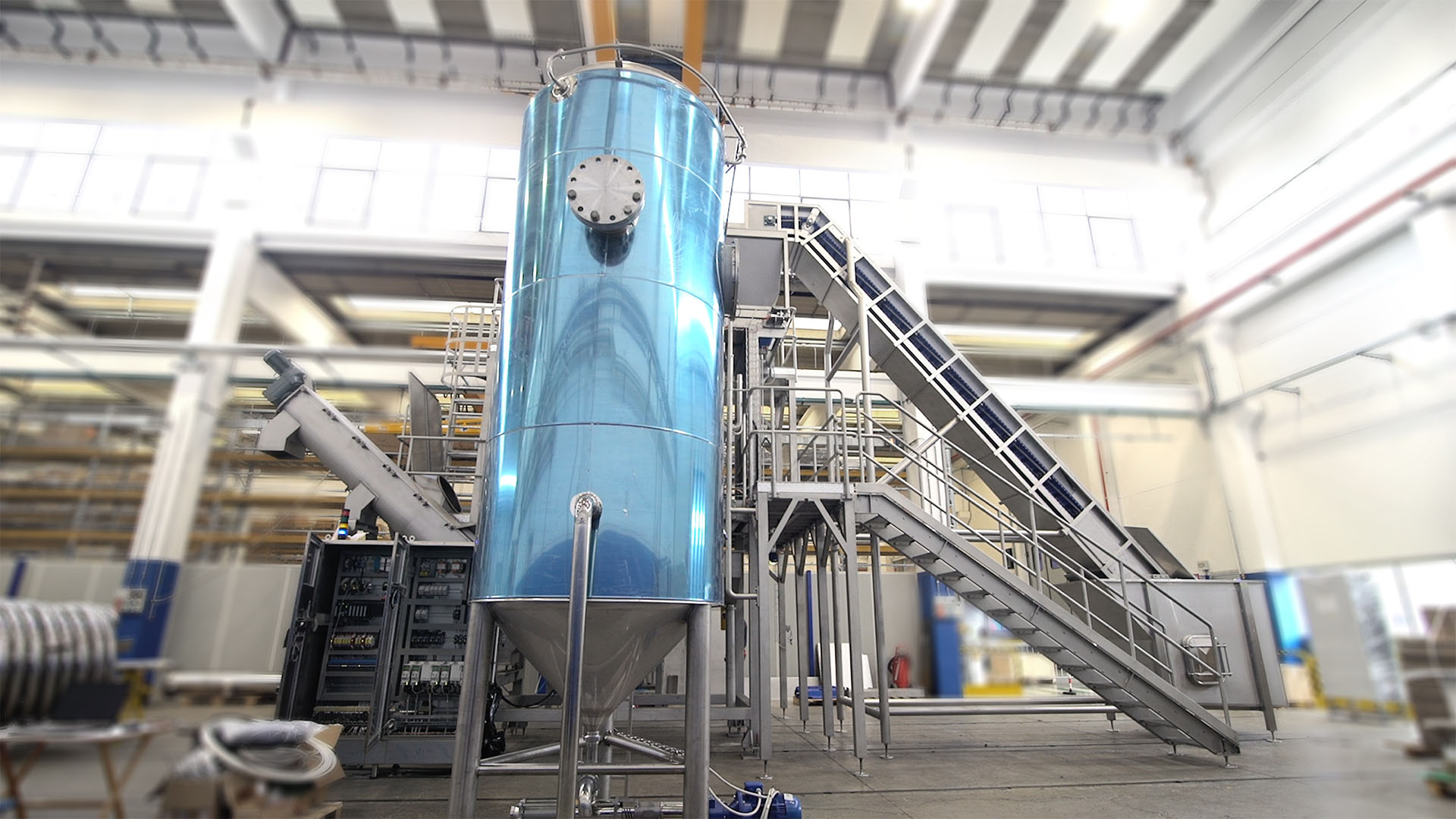

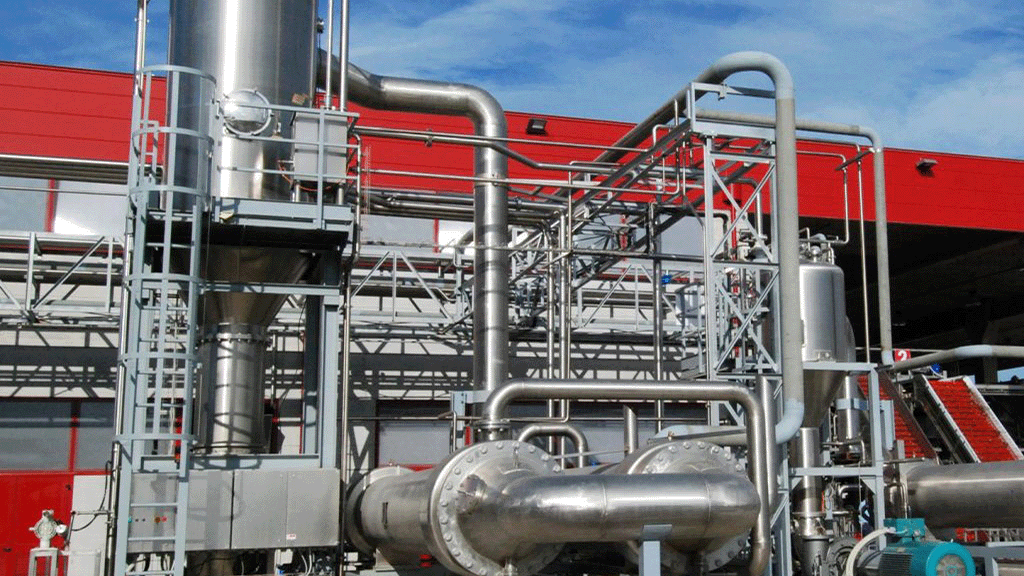

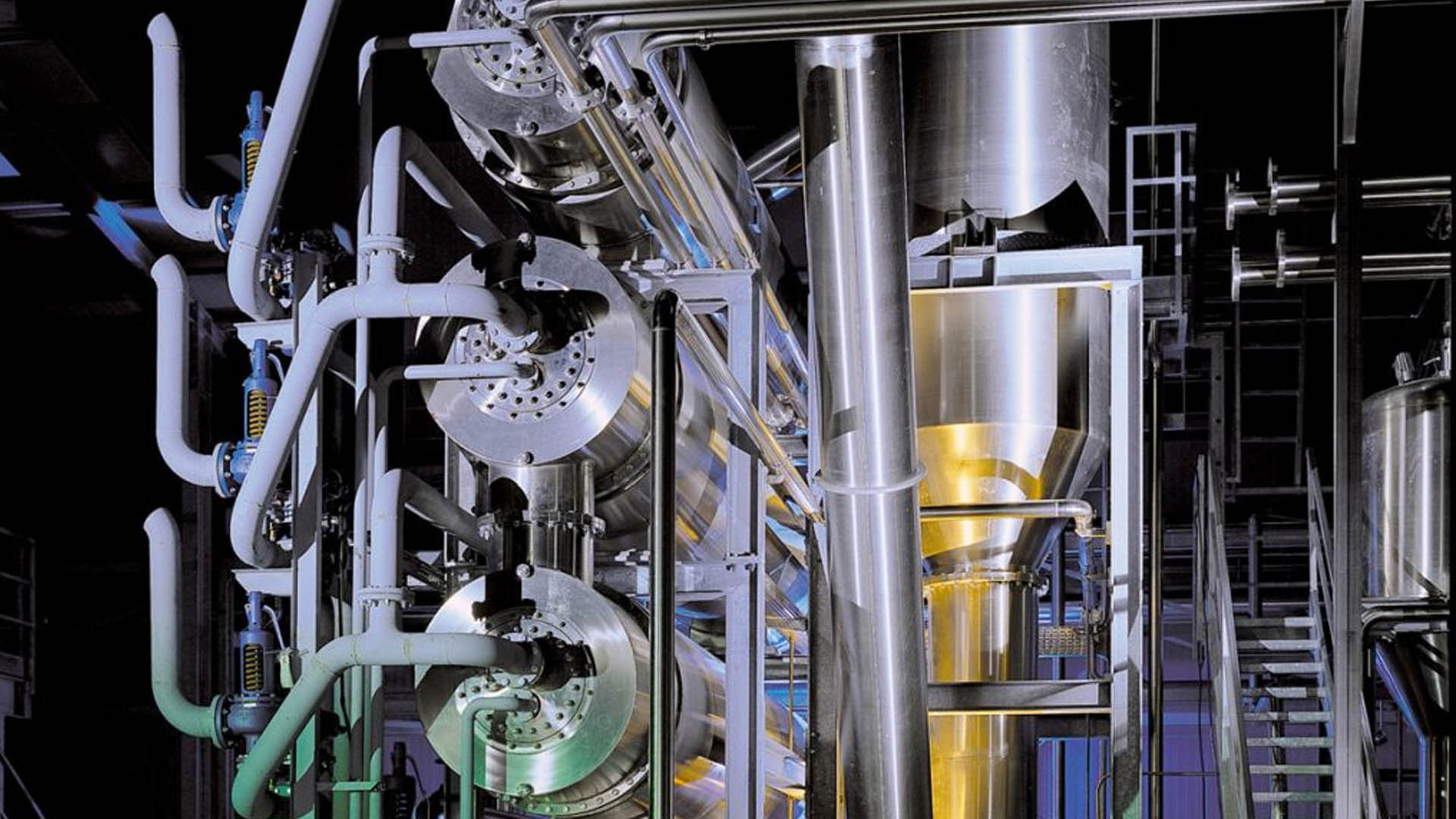

Concentration

Concentration

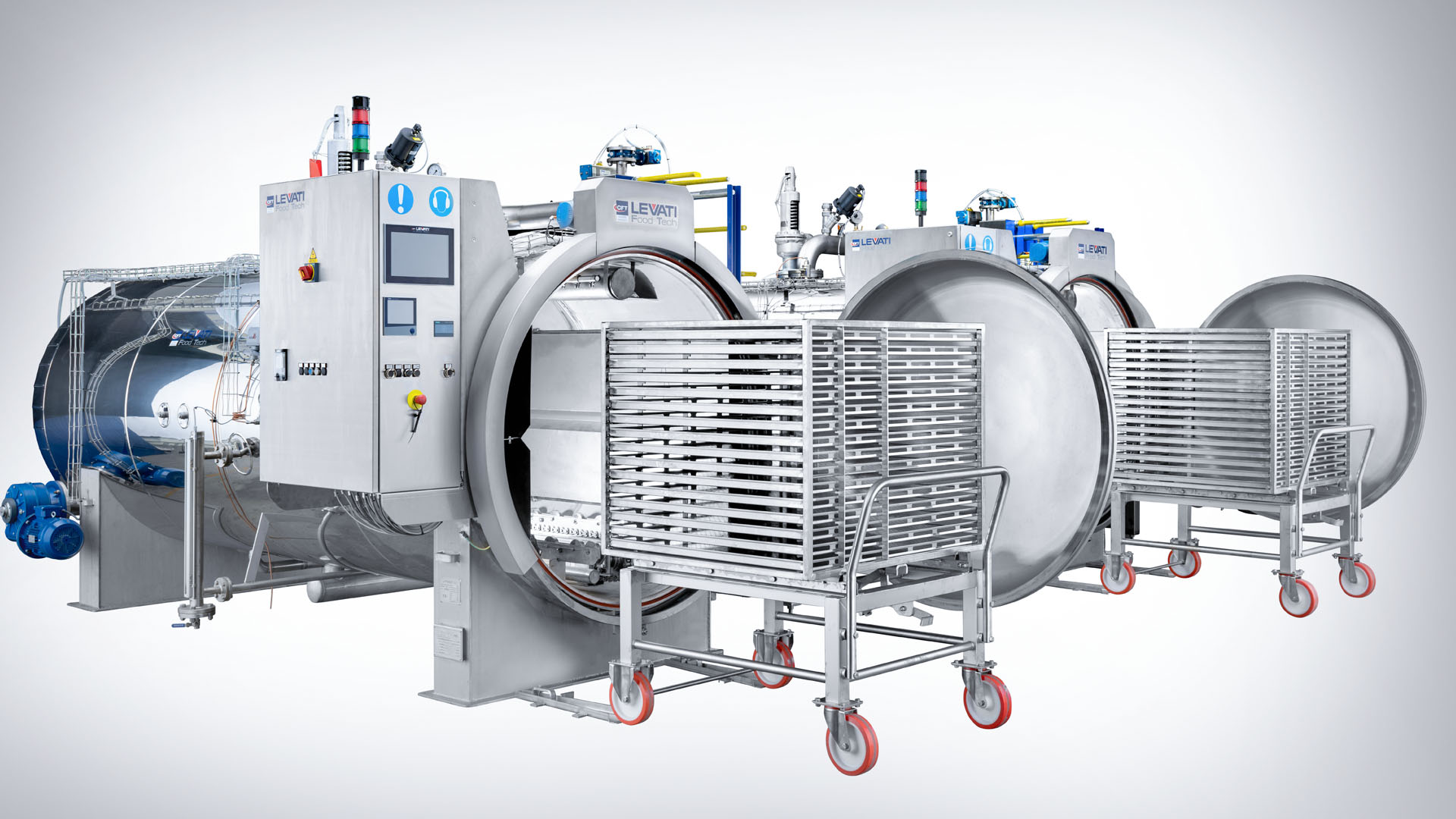

Sterilization & Cooling

Sterilization & Cooling

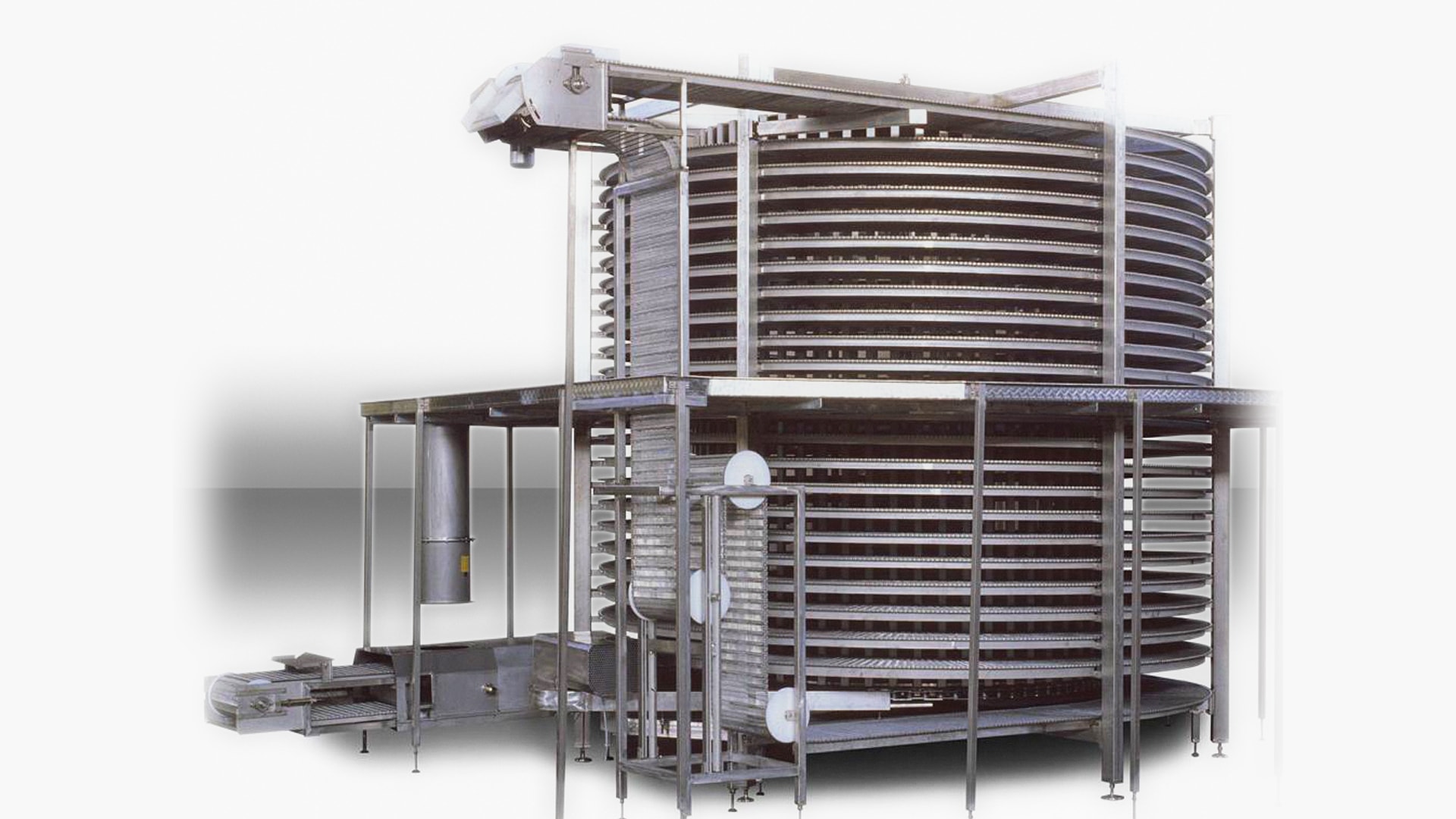

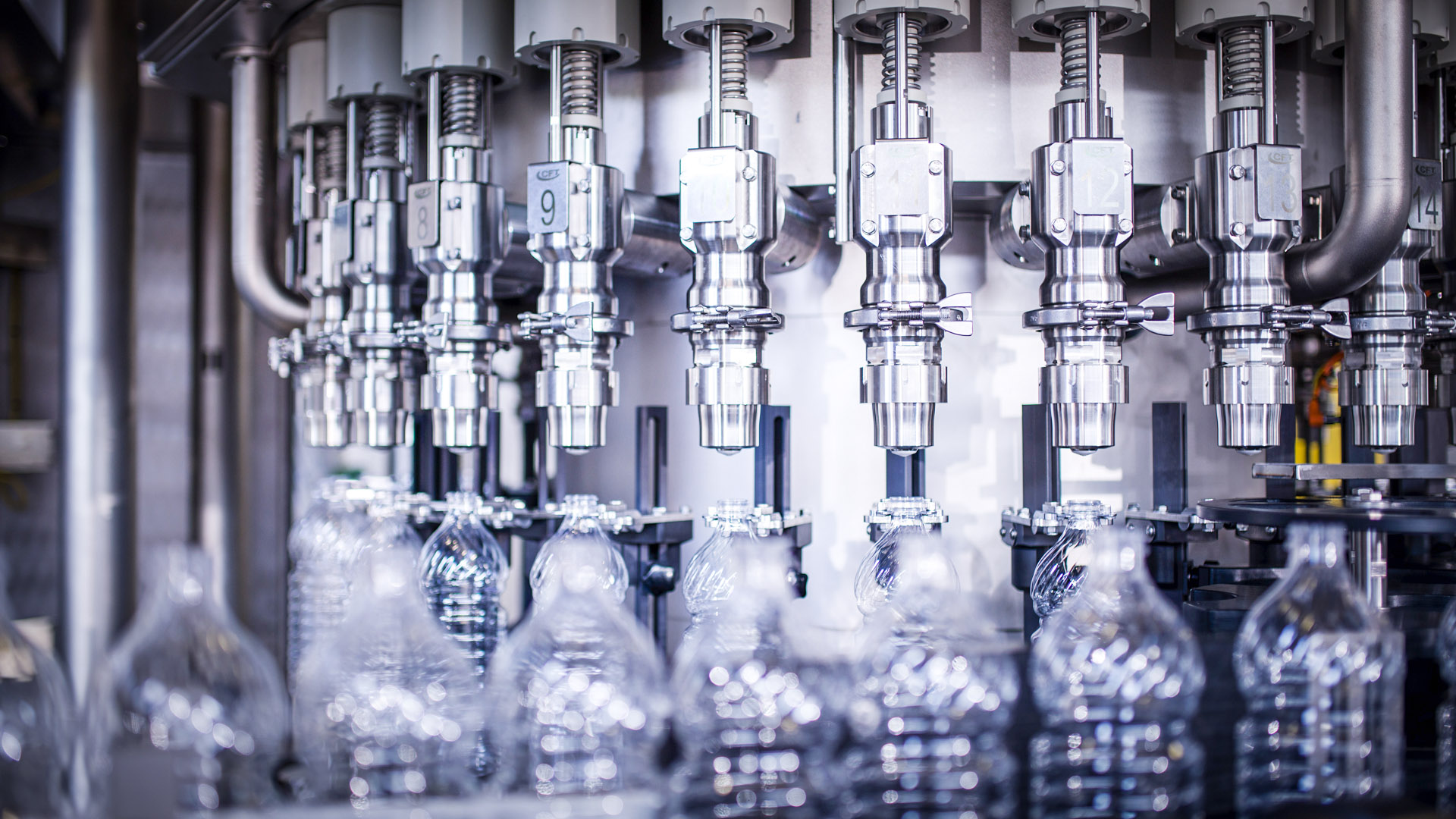

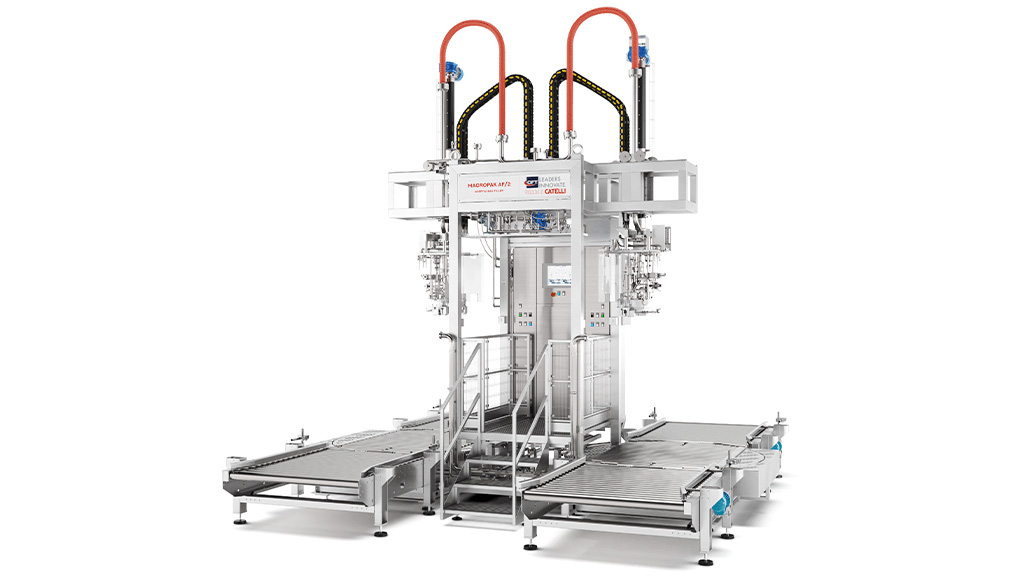

Aseptic Filling

Aseptic Filling