The evolution of evaporators: from conventional to hybrid

If there is a single thread running through the history of the CFT Group, it must be represented by tomato processing. Always a leader in the industry, CFT has developed complete, fully automated lines for making tomato concentrates and semi-concentrates using the Cold Break and Hot Break processes.

It is no coincidence therefore that the history of the Group is profoundly linked to the birth and evolution of evaporators. Starting with Rossi & Catelli’s original evaporator, patented in 1957, a vast range of evaporation technologies have been developed over the years for use in all areas of the food industry, especially in tomato processing, where the water must be removed from the raw material to assure a highly concentrated finished product.

In order to maximise energy efficiency and flexible production while maintaining the original organoleptic properties of the product, CFT has recently developed a number of hybrid evaporation solutions, in confirmation of its commitment to constant innovation.

This is a major advance in the history of evaporation, which would not have been possible without the fundamental developments preceding it, from the conventional Venus evaporator to the most recent Mixflow version.

How to apply these technologies to your plant?

The Venus evaporator

The Venus is a standard triple effect evaporator which employs the principle of forced downwards circulation of the product, with the heat exchanger mounted directly above the expansion chamber.

Thanks to its structural characteristics, the average temperature at which the product circulates is kept low, thus assuring excellent colour and consistency. The Venus is thus the best evaporator for the production of high viscosity tomato concentrates.

The Apollo MVR pre-evaporator

The Apollo MVR (Mechanical Vapour Recompression) falling film evaporator was launched in 2003: this was the first MVR technology applied to tomato concentration, with up to 98{46ec2a3493715af7728c32a403f8e2e213c1486a2b6674762cf12f27ee9af20a} steam savings thanks to its mechanical recompression of acidic vapours.

This evaporator can extract from 10 t/h to 80 t/h of evaporated water, and offers unbeatable reliability combined with delicate processing. The low dwell time and minimal ΔT between the heating steam and the product enables the machine to perfectly retain the original organoleptic characteristics of the product. In this way, the Apollo MVR considerably reduces running costs while improving production quality and capacity.

The Mixflow MVR evaporator

The Mixflow evaporator, one of the most recent series of evaporators designed and made by CFT, is a concentration unit which employs mixed circulation. It can be designed combined with a variety of multiple effect configurations: the double effect version is widely used for fruit purées, while the triple effect version is the most common one.

A new solution: the hybrid evaporator

Having reviewed the characteristics of CFT evaporators as separate units, we now look at their flexibility in use, especially in combination. Combining these technologies can be of great value in splitting the evaporation process to obtain high viscosity, high concentration and pulpy products in a convenient fashion. Furthermore, a hybrid solution which leverages the strengths of these separate technologies also offers excellent energy savings.

The hybrid evaporator: Apollo MVR – Mixflow MVR – Venus

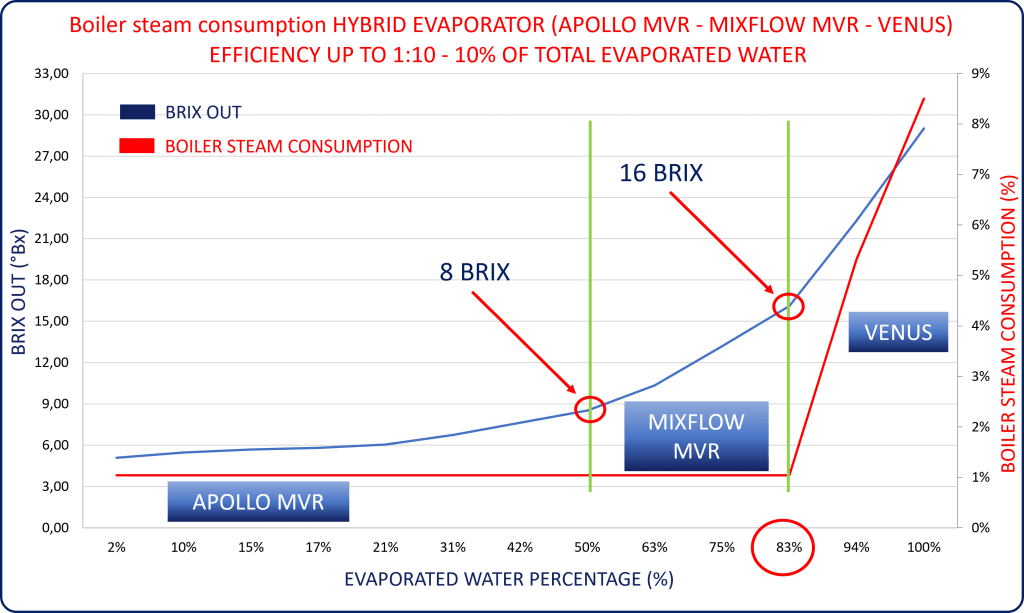

The hybrid evaporator par excellence is represented by the combined use of the Apollo MVR, Mixflow MVR and Venus. We can summarise the three elements of this combination as follows:

- The Apollo MVR is ideal for the pre-concentration stage (5° to 8-10° Bx) and maintaining the colour and flavour of the product;

- The Mixflow evaporator concentrates the product even further (up to 15-16° Bx);

- The final stage of concentration is then handled by the Venus, which is the only evaporator capable of achieving the maximum requested concentration.

Benefits

1. Energy efficiency

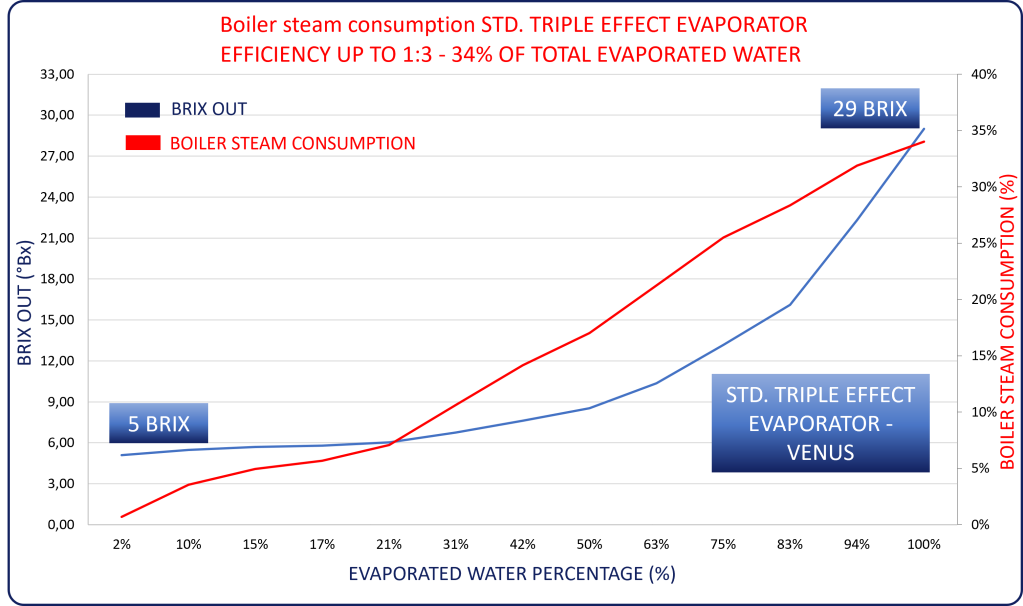

The MVR technology can be applied up to a maximum concentration of around 16° Bx, which corresponds to removing 83{46ec2a3493715af7728c32a403f8e2e213c1486a2b6674762cf12f27ee9af20a} of the total evaporated water, and considerably reduces the steam consumption curve in comparison to the Venus used by itself.

The efficiency of the Venus, when used alone, is much lower than that of the combination of these three technologies. Standard evaporation starts with an efficiency of 1:3, which represents the amount of steam (1 kg) required to evaporate 3 kg of water; the hybrid evaporation solution, on the other hand, achieves an efficiency ratio of more than 1:10, i.e. 1 kg of steam to evaporate around 10 kg of water. This reduction in the use of steam adds up to a drastic reduction in gas consumption.

Graphs 1-2. Boiler steam consumption: Standard vs Hybrid Evaporator

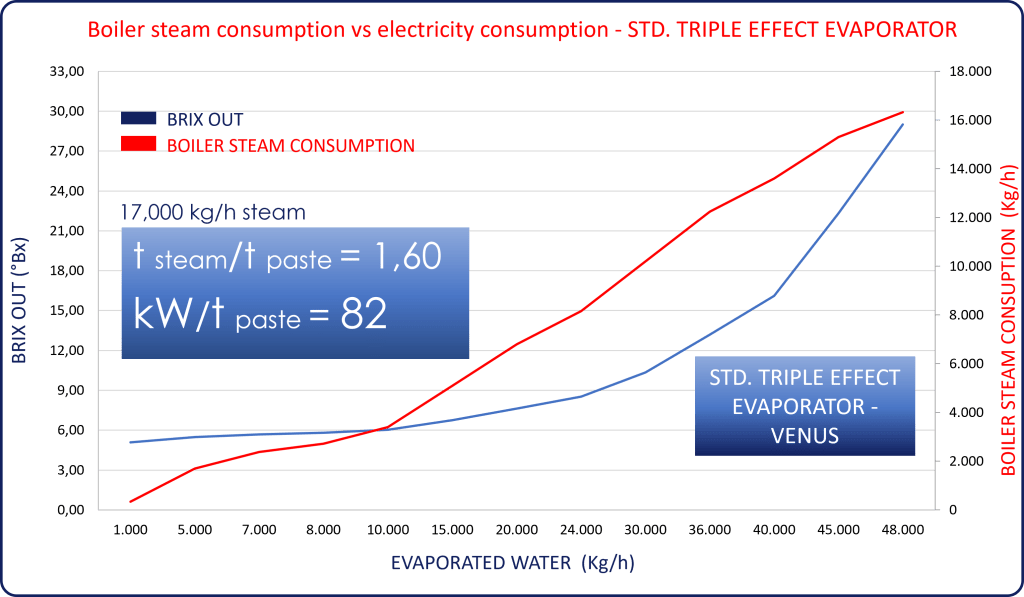

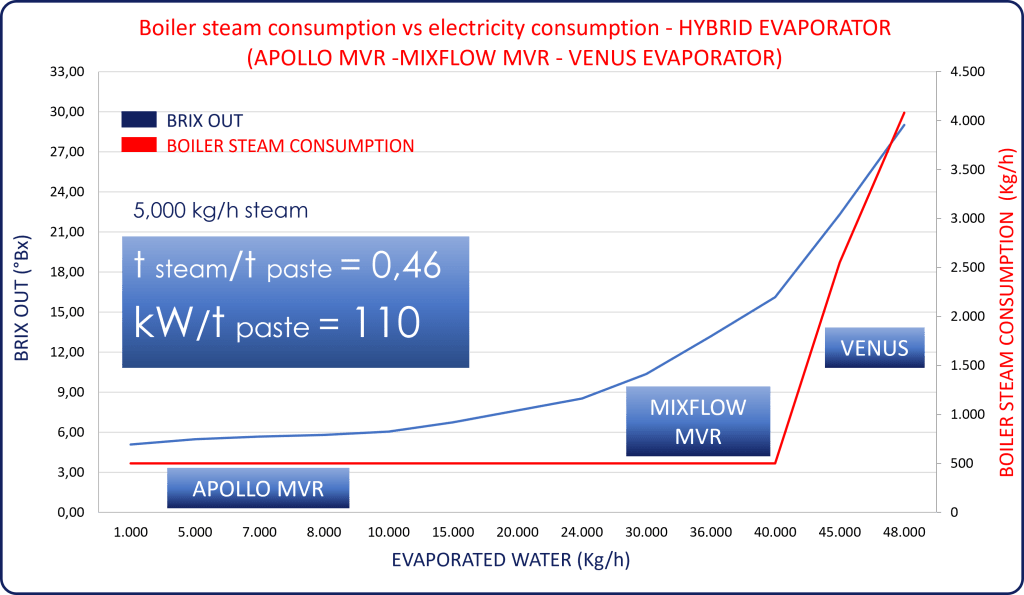

Although the MVR technology may consumes more electricity (in the case of using a compressor powered by an electric motor), the hybrid evaporator remains a clearly more energy efficient solution.

Graphs 3-4. Energy Efficiency: Standard vs Hybrid Evaporator

2. Tax and environmental benefits

Making your system more efficient by opting for a hybrid evaporator solution also has other, implicit benefits. In a world in which sustainability is the goal in every industry, one must consider not just the environmental benefits, but also the economic benefits of eco-friendly production. We are thinking of governmental incentives for companies that adopt technologies to reduce greenhouse gas emissions and, on the other hand, sanctions like the carbon tax on companies whose operations are not environmentally sustainable.

How to apply these technologies to your plant?

3. Reduced running costs

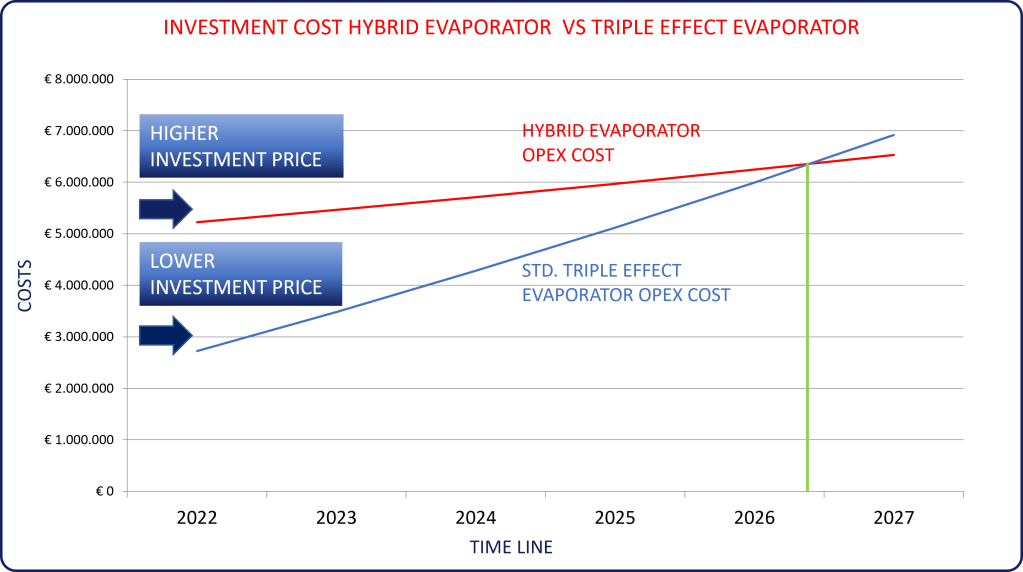

The very nature and complexity of the hybrid evaporator solution necessarily demands a higher initial investment than a triple-effect evaporator. However, this initially higher cost is recovered in under four years thanks to the greatly reduced running costs of a hybrid installation. The running costs of a standard evaporator, in contrast, increase exponentially over time, much faster than those incurred by the combined Apollo MVR – Mixflow MVR – Venus solution.

Graph 5. Investment and OPEX costs: Standard vs Hybrid Evaporator

Further combinations

The three evaporative concentration technologies in question, once installed, can be combined as explained in the previous paragraphs to obtain a highly concentrated product. What is more, the combined systems can be used in a variety of ways, not only all together but also individually or in pairs, to obtain products with different concentrations, like tomato purée and tomato sauces.

Roberto Montani – Primary Process Manager

Gabriele Botti – Product Specialist